Multi-cylinder internal combustion engine and method for operating such a multi-cylinder internal combustion engine

A technology of internal combustion engines and cylinders, applied in the direction of engine components, engine ignition, machines/engines, etc., can solve problems such as energy defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

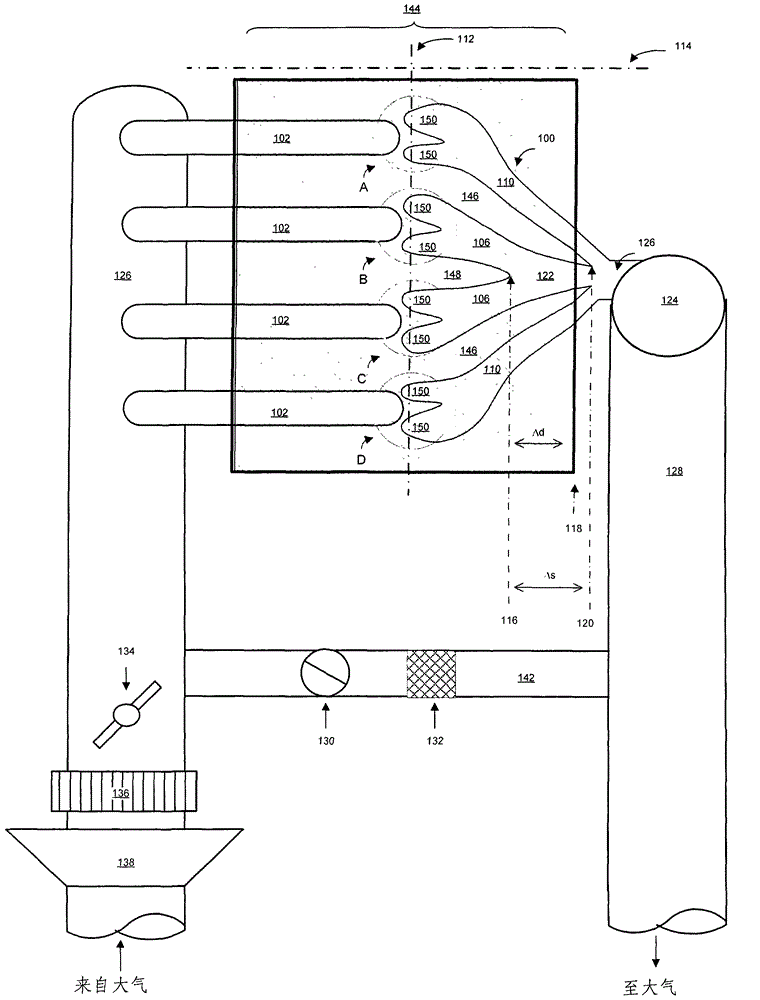

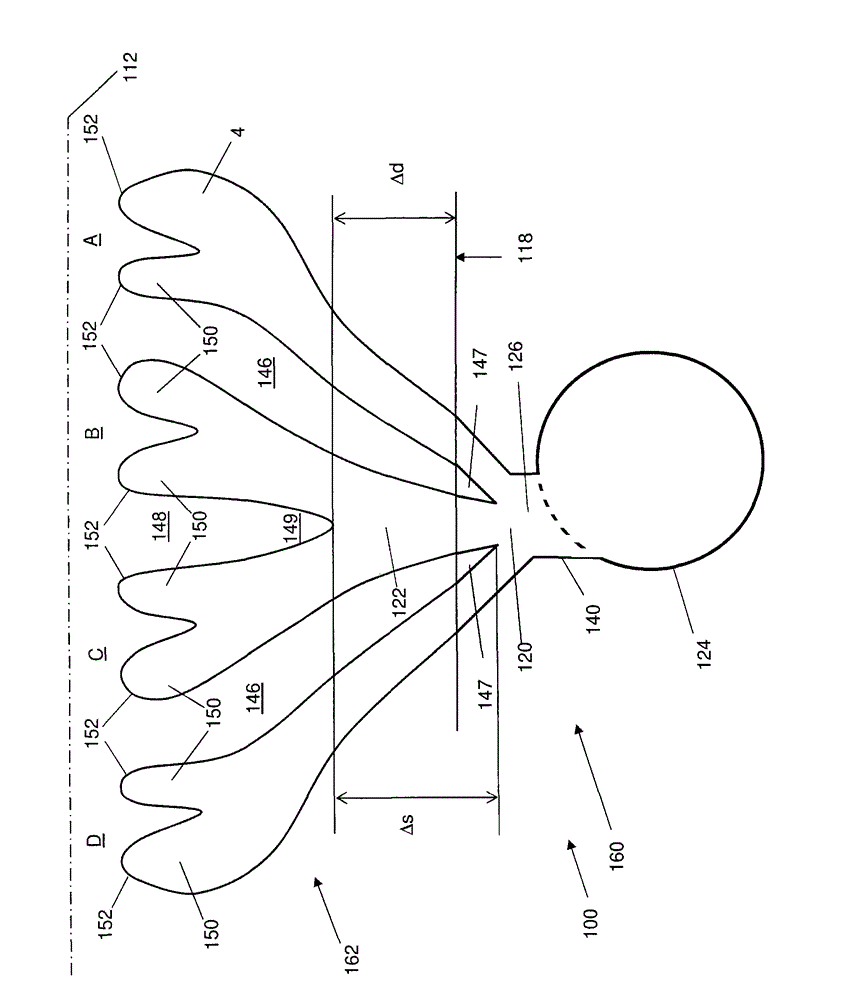

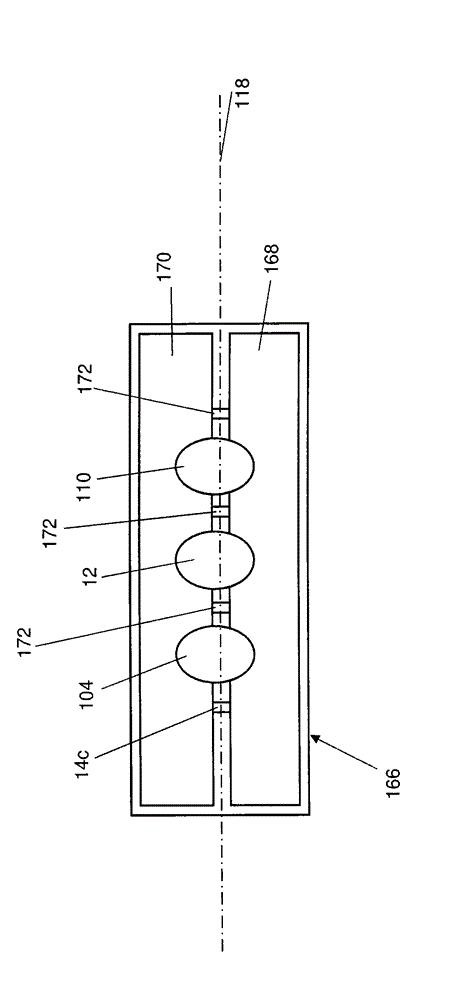

[0012] In an engine, the cylinder head is often used to hold the valve train. To control charge changes, engines often use control elements and actuators to actuate the control elements. Against the background of charge changes, combustion gases are expelled through the exhaust port and fresh mixture or fresh air is introduced through the intake port, filling the combustion chamber. To control charge changes, reciprocating valves are used as control elements in almost all four-stroke engines. The reciprocating valves undergo an oscillating reciprocating motion during engine operation and thereby open and close the intake and exhaust ports. The valve train is the valve actuation mechanism that moves the valves. Valve actuation devices often include a camshaft on which a plurality of cams are arranged.

[0013] The function of the valve gear is to open and close the intake and exhaust ports of the cylinder at just the right time, where the purpose is to quickly open a flow cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com