Anisotropic conductive adhesive, conductive film, and electrical connection method

An anisotropic, conductive adhesive technology, applied in the field of electrical connection, can solve problems such as inability to apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

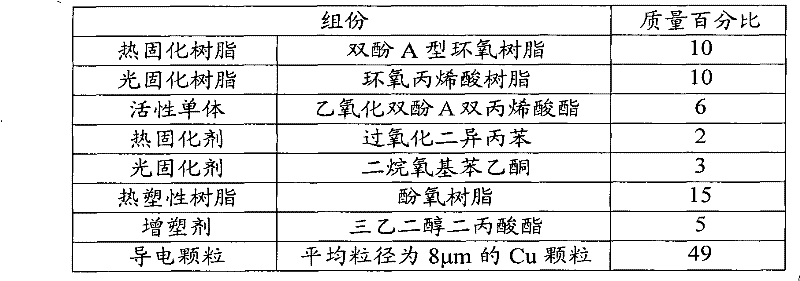

[0048] The components contained in the anisotropic conductive adhesive 2 made into the dry film in this embodiment and their respective mass percentages (relative to 100w% dry film conductive adhesive) are shown in Table 1:

[0049] Table 1

[0050]

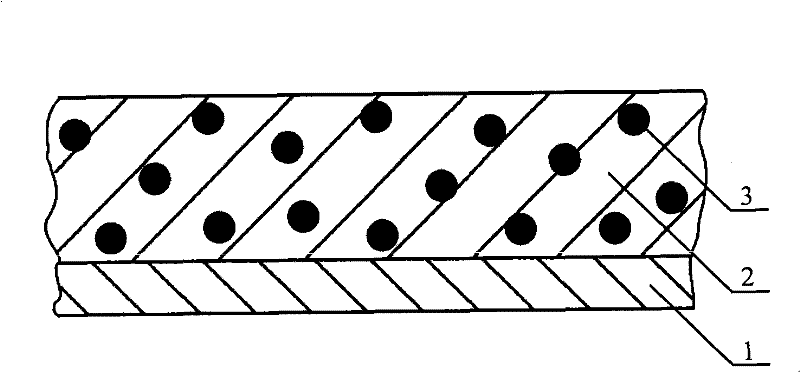

[0051] The anisotropic conductive adhesive 2 was coated on the PET protective base tape 1 with a thickness of 15 μm to form a dry film, and the thickness of the dry film was 40 μm.

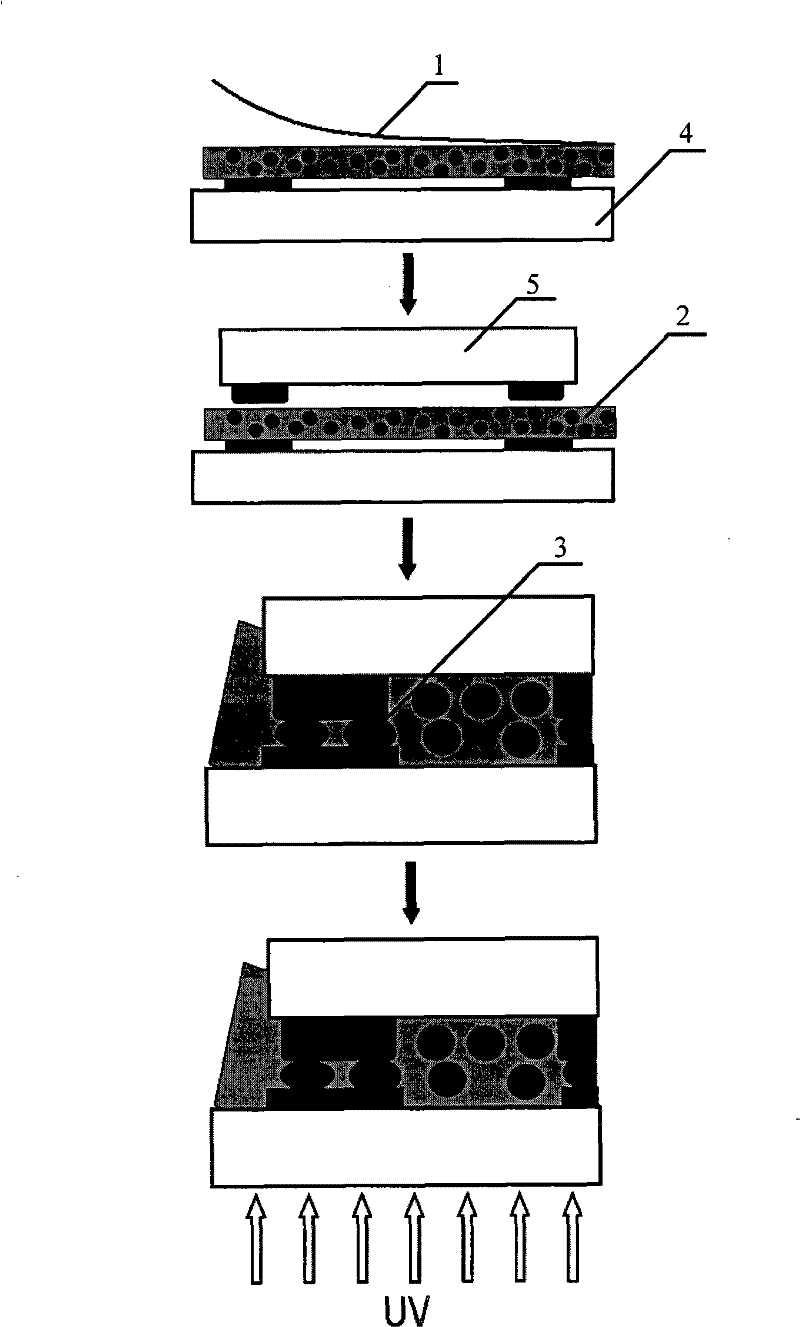

[0052] Use the anisotropic conductive film in the present invention for electrical connection:

[0053] Step 1: Cut a certain length of anisotropic conductive film as required, press it on the electrode terminal of the glass substrate 4 at 40°C, peel off the protective base tape 1, and form anisotropic conductive adhesive 2 on the electrode terminal ;

[0054] Step 2: Precisely align the 5 electrodes of the flexible circuit to be electrically connected with the 4 electrodes of the glass substrate, and then perform pre-pressing;

[0055] Step 3:...

Embodiment 2

[0057] The components contained in the anisotropic conductive adhesive 2 made into the dry film in this embodiment and their respective mass percentages (relative to 100w% dry film conductive adhesive) are shown in Table 2:

[0058] Table 2

[0059]

[0060] The anisotropic conductive adhesive 2 is coated on a 20 μm thick PET protective base tape 1 to form a dry film, and the dry film thickness is 30 μm.

[0061] Use the anisotropic conductive film in the present invention for electrical connection:

[0062] Step 1: Cut a certain length of anisotropic conductive film as required, press it on the electrode terminal of the glass substrate 4 at 50°C, peel off the protective base tape 1, and form anisotropic conductive adhesive 2 on the electrode terminal ;

[0063] Step 2: Precisely align the 5 electrodes of the flexible circuit to be electrically connected with the 4 electrodes of the glass substrate, and then perform pre-pressing;

[0064] Step 3: Carry out pressure on th...

Embodiment 3

[0066] The components contained in the anisotropic conductive adhesive 2 made into the dry film in this embodiment and their respective mass percentages (relative to 100w% dry film conductive adhesive) are shown in Table 3:

[0067] table 3

[0068]

[0069] The anisotropic conductive adhesive 2 is coated on a 25 μm thick PET protective base tape 1 to form a dry film, and the dry film thickness is 45 μm.

[0070] Use the anisotropic conductive film in the present invention for electrical connection:

[0071] Step 1: Cut a certain length of anisotropic conductive film as required, press it on the electrode terminal of the glass substrate 4 at 55°C, peel off the protective base tape 1, and form anisotropic conductive adhesive 2 on the electrode terminal ;

[0072] Step 2: Precisely align the 5 electrodes of the flexible circuit to be electrically connected with the 4 electrodes of the glass substrate, and then perform pre-pressing;

[0073] Step 3: Carry out pressure on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com