Method for mounting spherical rib-ring-shaped rope vault structure by geometric method

A cable dome, rib ring technology, applied in the direction of roof, building components, building structure, etc., can solve problems that are difficult to master and require high computing technology, and achieve the effect of clear concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

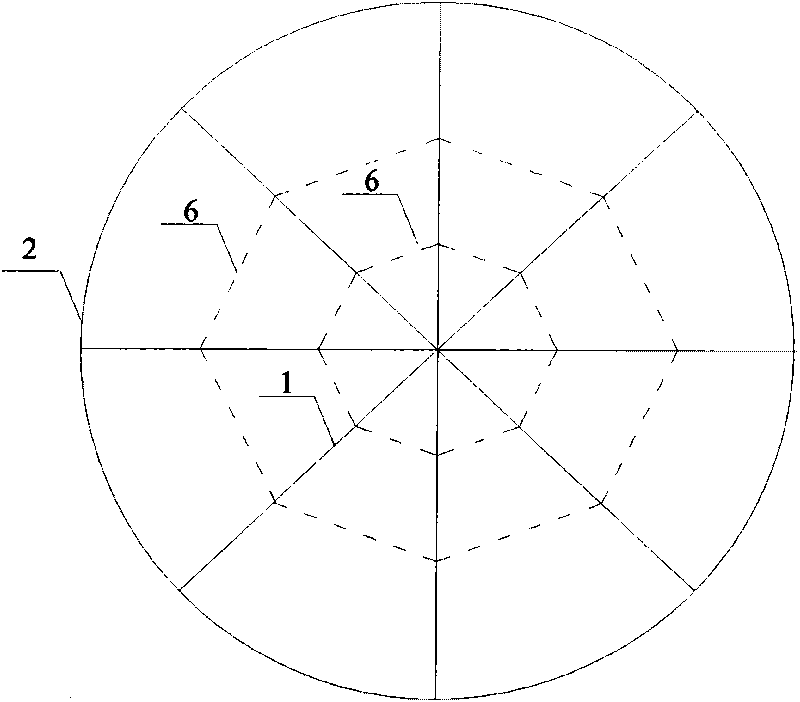

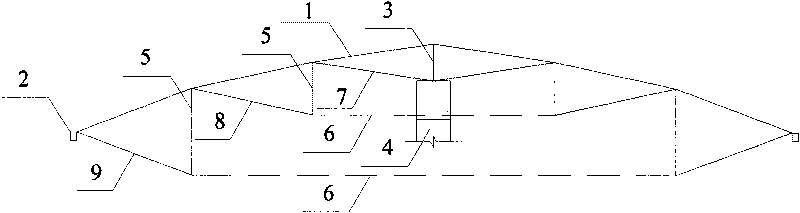

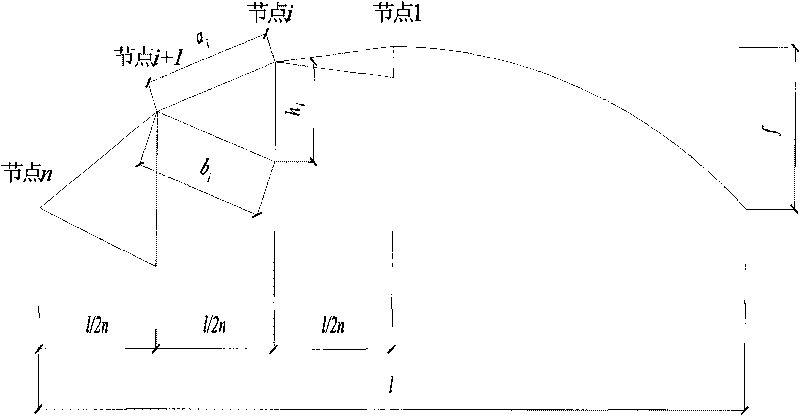

[0020] The method of installing the spherical rib ring cable dome structure with the geometric method is: firstly, the ridge cable 1 is connected and suspended on the compression ring beam 2, and then the ridge cable 1 is connected with one end of the central vertical compression rod 3, and the lower part is a temporary installation scaffold 4, and Lift the central vertical strut 3 to the design elevation, and its elevation point is the apex elevation of the cable dome, then one end of the central oblique cable 7 is connected to the ridge cable 1, and the other end of the central oblique cable 7 is connected to the other end of the central vertical strut 3, and then From the inside to the outside, connect one end of the vertical compression rod 5 with the ridge cable 1, the ring cable 6 with the other end of the vertical compression rod 5, one end of the diagonal cable 8 with the ridge cable 1, and the other end of the diagonal cable 8 with the other end of the vertical compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com