Method for determining pile spacing of anti-liquefying vibrating-impacting crushed-stone piles

A technology of vibrating crushed stone piles and pile spacing, which is applied in the fields of instrumentation, calculation, electrical digital data processing, etc., can solve the problem that the pile spacing is too safe, the total investment of the project is increased, and the drainage and shock absorption effects of the crushed stone piles are not considered. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings.

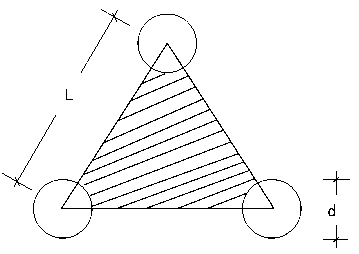

[0056] The present invention is based on the test pile area of a 220 kV substation foundation site, and the effective pile diameter of the vibrating gravel piles is 0.9m, the pile distance is 2m, the pile length is 10.5m, and the piles are arranged in an equilateral triangle.

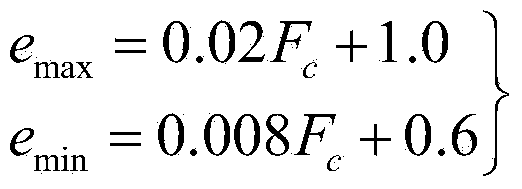

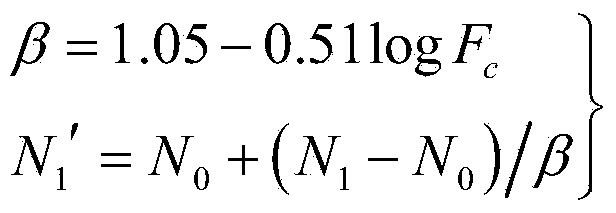

[0057] The method of determining the spacing between gravel piles is divided into three steps: judging the degree of liquefaction of the foundation soil according to the in-situ test, determining the dry density of the foundation soil between the piles required to eliminate liquefaction, and determining the pile spacing of the gravel piles. The details are as follows:

[0058] (1) Judging the degree of liquefaction of the foundation soil according to the in-situ test: the liquefaction judgment method of the foundation soil can adopt the following three methods or one of them;

[0059] 1) Crit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com