Motor device of top opening barrel washing machine for accurately halting and positioning

A front-loading washing machine and a top-opening technology, which is applied to washing devices, other washing machines, stopped devices, etc., can solve the problems of complex, difficult, and inability to accurately locate, and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

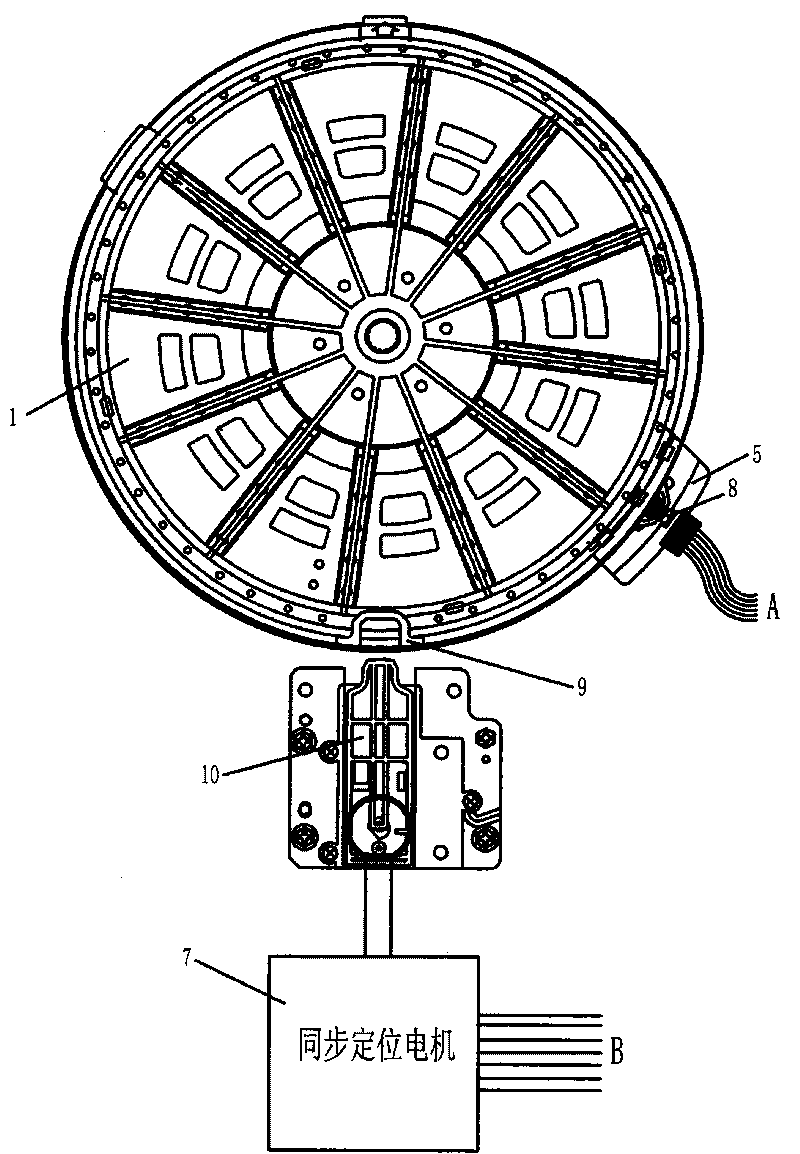

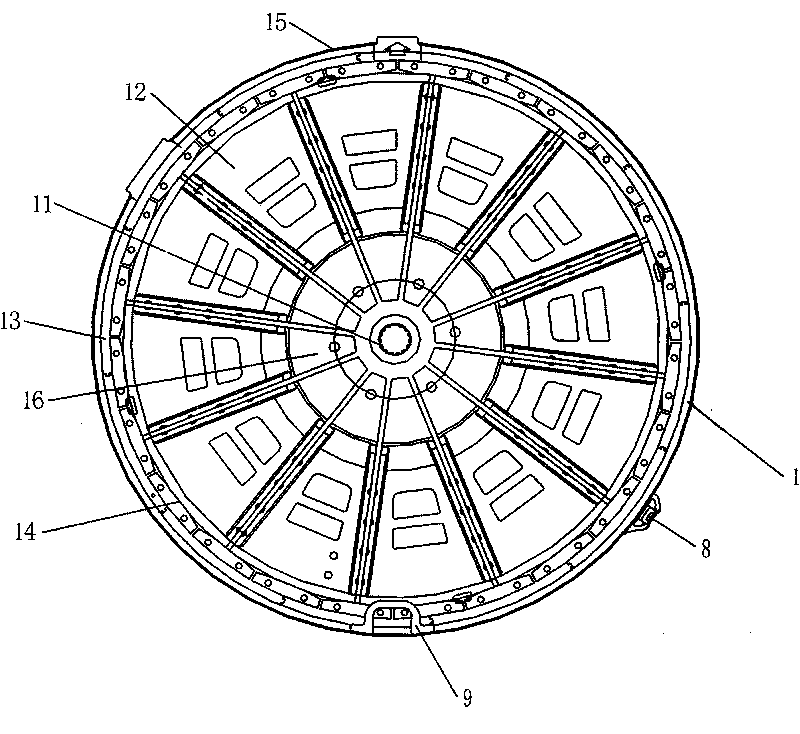

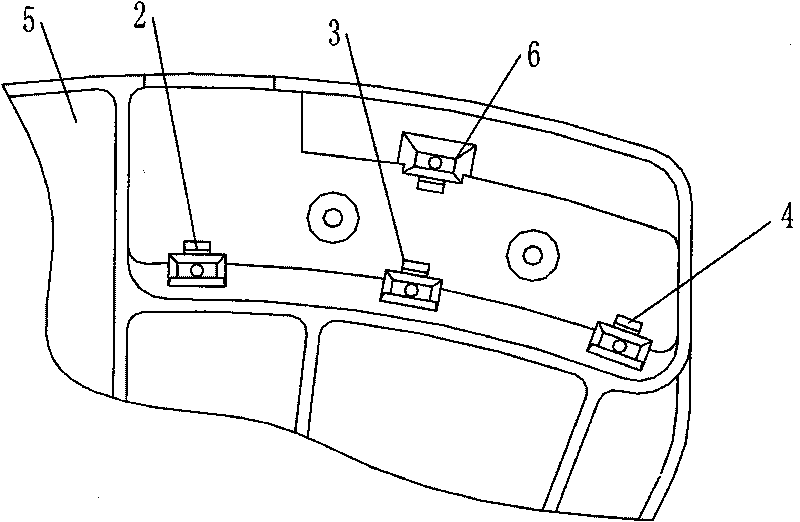

[0015] A motor device for accurate shutdown positioning of a top-loading drum washing machine. The washing tub of the washing machine is composed of an outer cylinder on the outer layer and an inner cylinder inside the outer cylinder. Both the inner and outer cylinders are located in the shell of the washing machine, and the motor is installed on the The side of the inner cylinder drives the inner cylinder to rotate, the inner wall of the outer cylinder is provided with a locking piece, and the motor is provided with a controller for controlling the locking piece to be in a locked position, and the controller controls the inner cylinder to make the inner cylinder Stay in position for loading or unloading laundry. The position where the clothes are put in or taken out refers to the position where the inner cylinder is at the position where the opening direction of the inner cylinder door faces upward. In the present invention, when the machine is shut down, the opening position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com