Modified fixing mechanism of riser and front fork vertical bar

A fixed mechanism, improved technology, applied in steering mechanism, transportation and packaging, bicycle accessories, etc., can solve the problem of not being suitable for men or women, and achieve the effect of humanized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

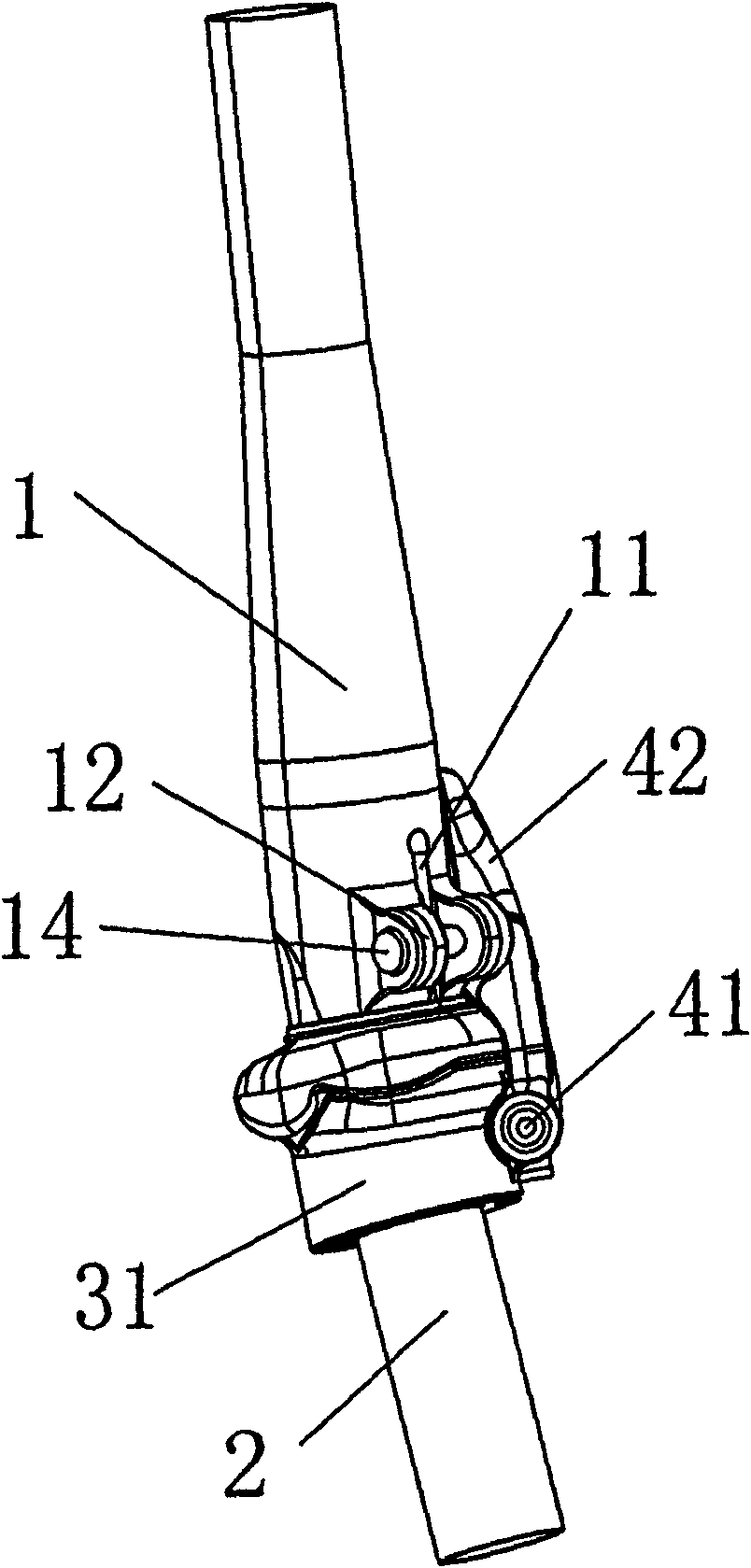

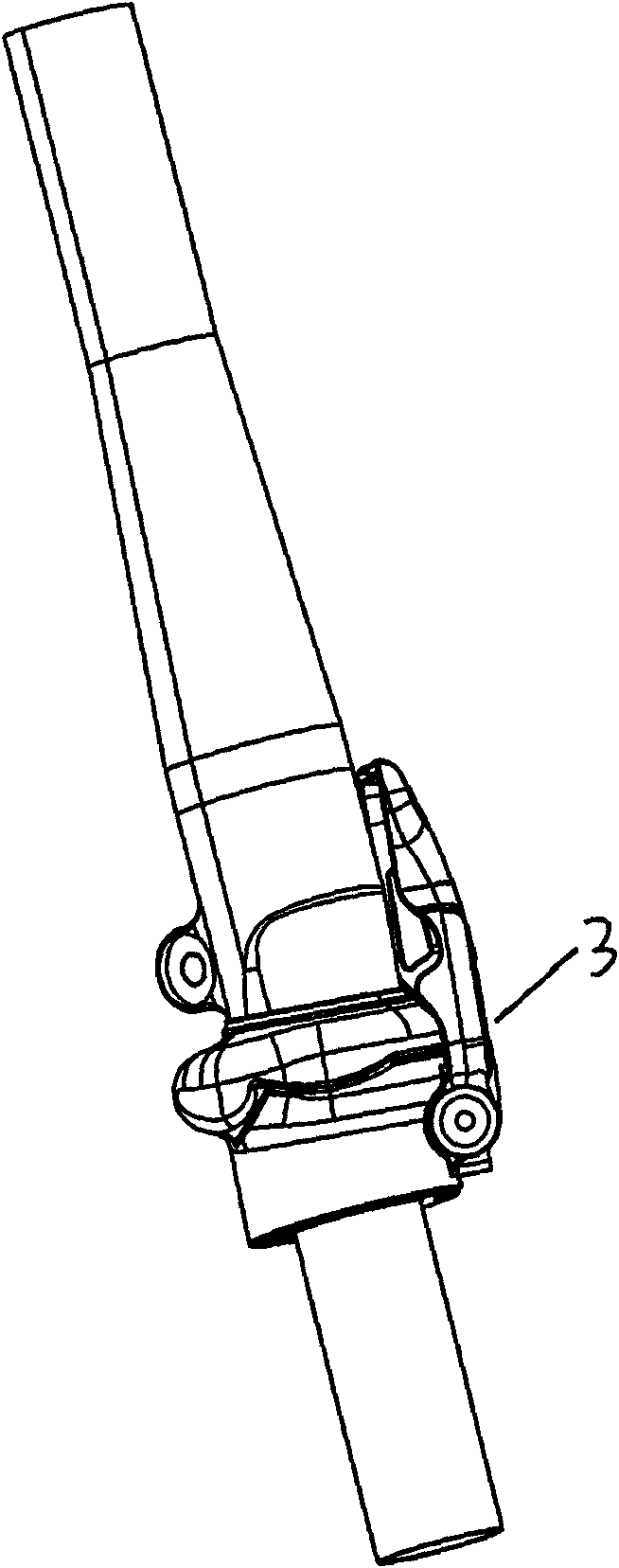

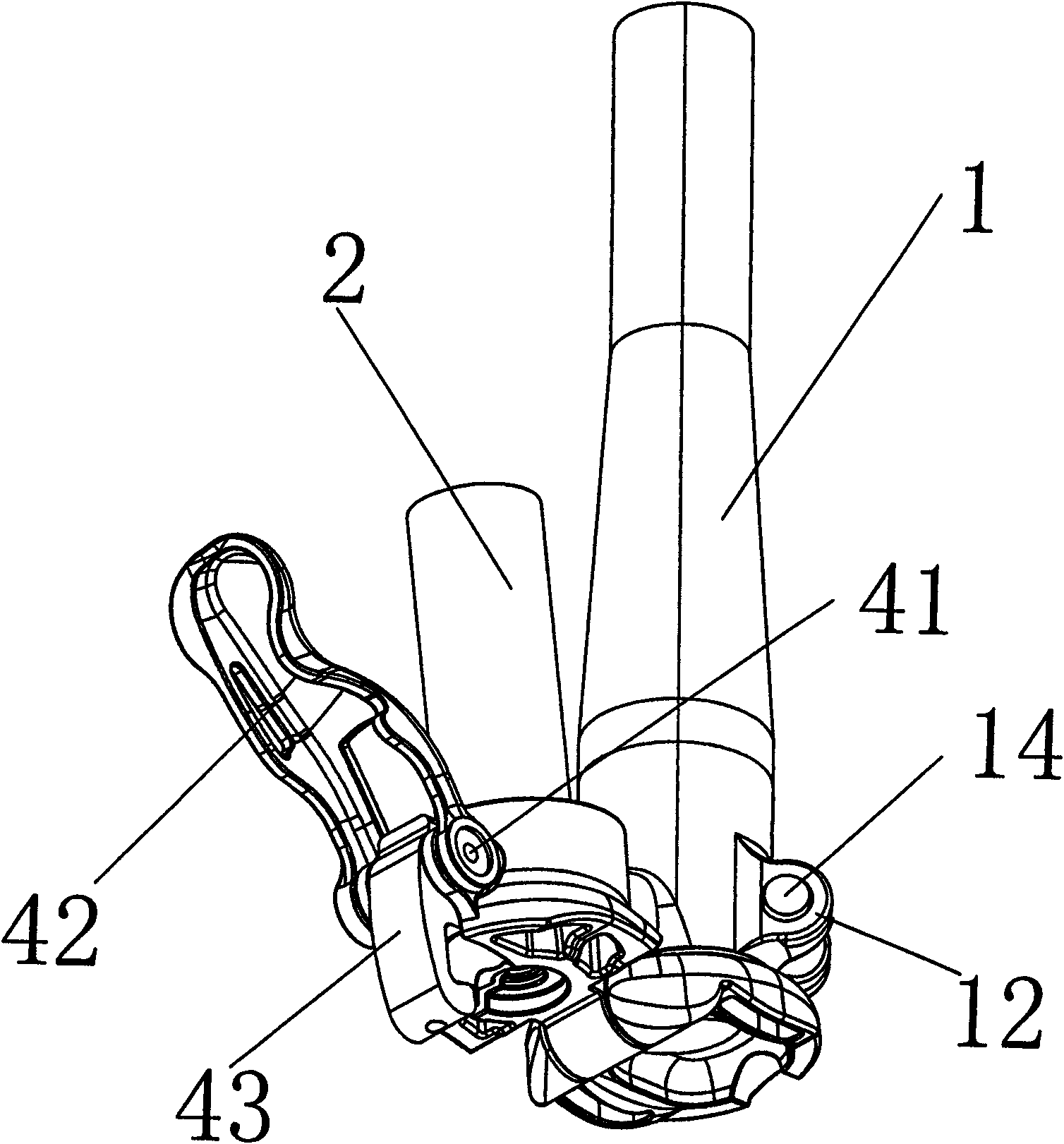

[0015] combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , as further described below:

[0016] A fixing mechanism for a standpipe and a front fork vertical bar, which is composed of a standpipe 1, a front fork vertical bar 2 and a folding joint 3 connecting the standpipe and the front fork vertical bar. The folding joint 3 is connected by a side hinge. The other side is composed of an upper folding seat and a lower folding seat that are folded and fixed by a quick release assembly. The upper folding seat is integrally formed with a positioning column 32 that can extend into the standpipe 1. The lower folding seat is integrally formed and can be placed on the front The lower casing 31 of the fork vertical bar 2, when the upper folding seat and the lower folding seat are fastened, an angle is formed between the central axis of the positioning column 32 and the central axis of the lower casing 31, and the lower casing The mouth of the 31 pipe is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com