Take-up winder

A winding machine and spinning technology, which is applied in the direction of filament generation, textile and papermaking, and conveying filamentous materials, etc. It can solve the problems of the number of guides, the lack of reference to the bending angle of the filament, and the deterioration of the filament quality, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]

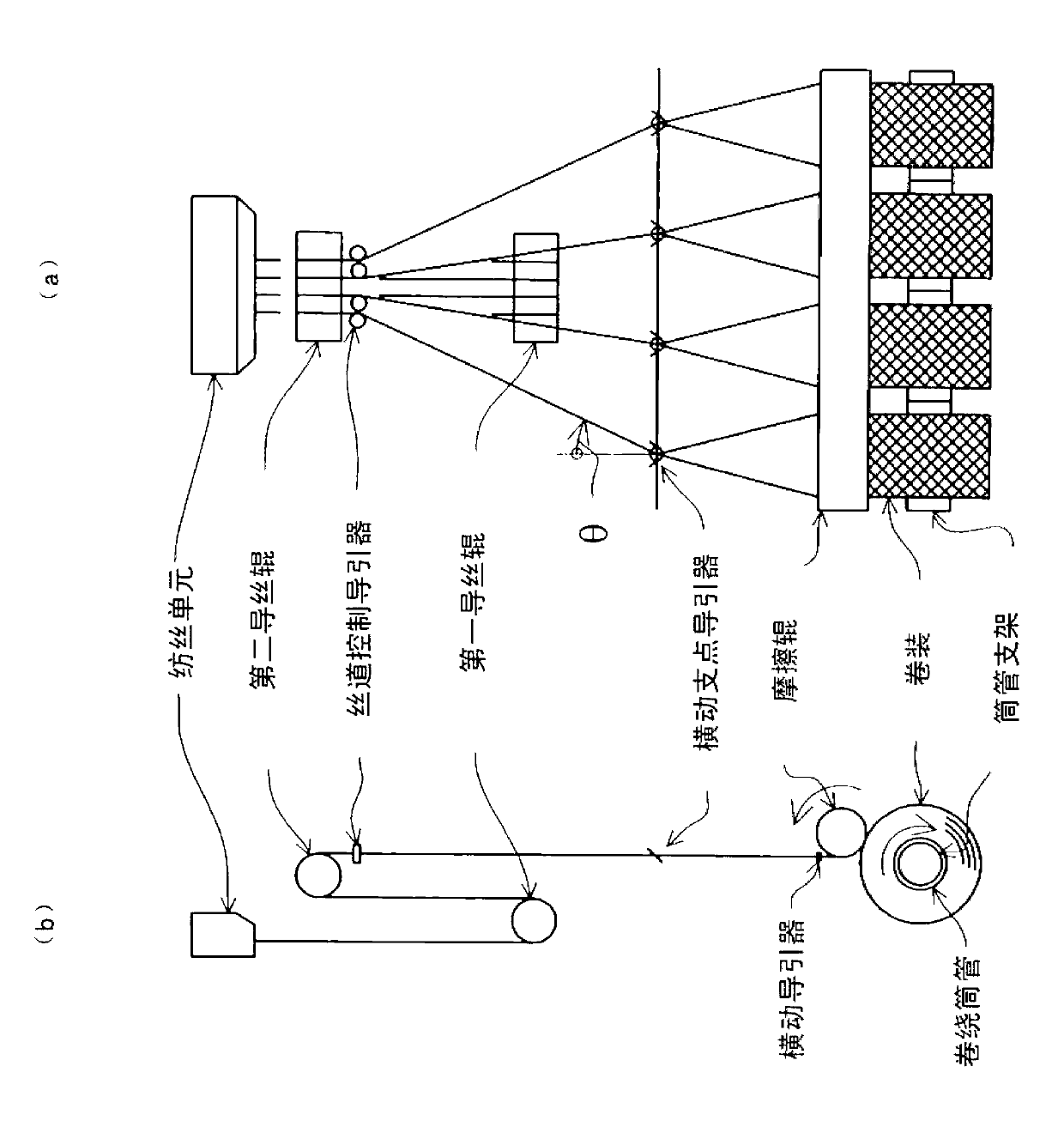

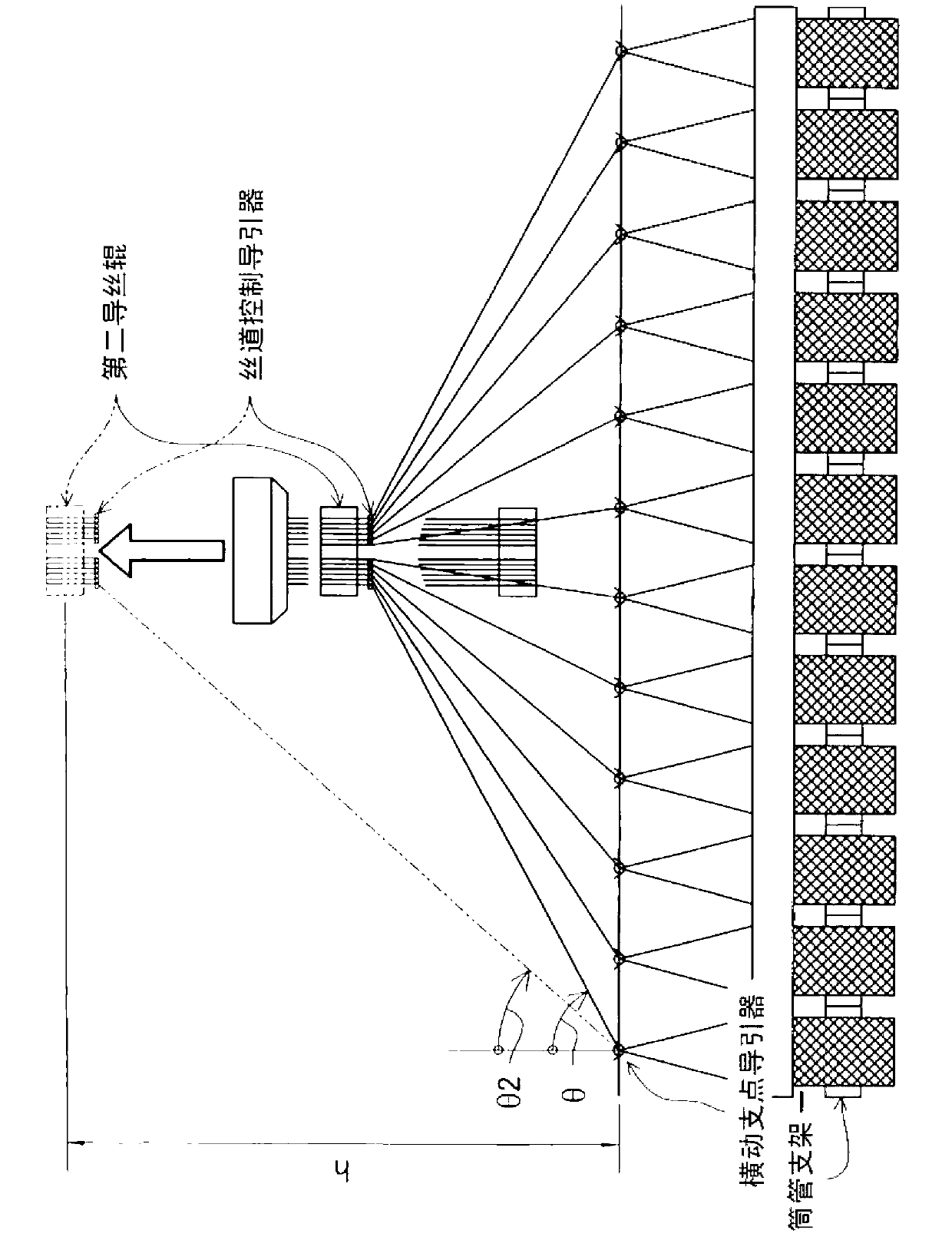

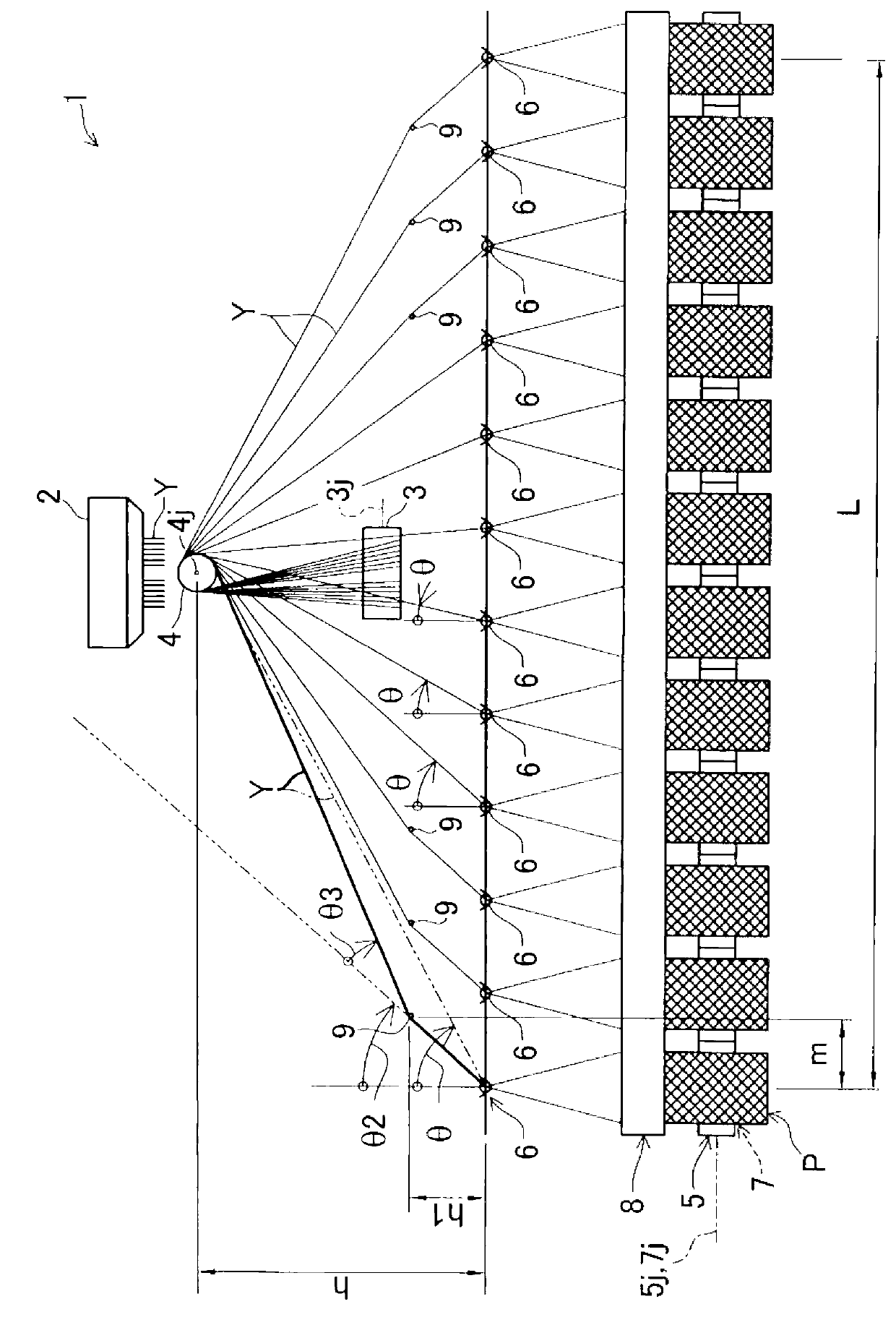

[0028] A first embodiment of the present invention will be described below with reference to the drawings. image 3 It is a front view of the spinning winder according to the first embodiment of the present invention. Such as image 3 As shown, the spinning winder 1 of this embodiment has a spinning unit 2, a first godet roll 3 and a second godet roll 4, a bobbin holder 5, and a traverse fulcrum guide 6 as main components.

[0029] The above-mentioned spinning unit 2 spins a plurality of yarns Y. In this embodiment, the yarn Y is a synthetic fiber yarn. In the present embodiment, the above-mentioned spinning unit 2 is configured to spin out 12 yarns Y at the same time.

[0030]The first godet roll 3 and the second godet roll 4 are sequentially arranged along the yarn path of the yarn Y spun by the spinning unit 2 to draw the yarn Y.

[0031] In detail, the first godet roll 3 is arranged vertically below the spinning unit 2 so that its axis direction 3j is aligne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com