Laterally emitting device and method of manufacturing same

A side and injection surface technology, which is applied in the field of side injection devices, can solve problems such as deterioration reliability, reduction, and unstable beam quality, and achieve the effect of reducing the number of parts and reducing the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

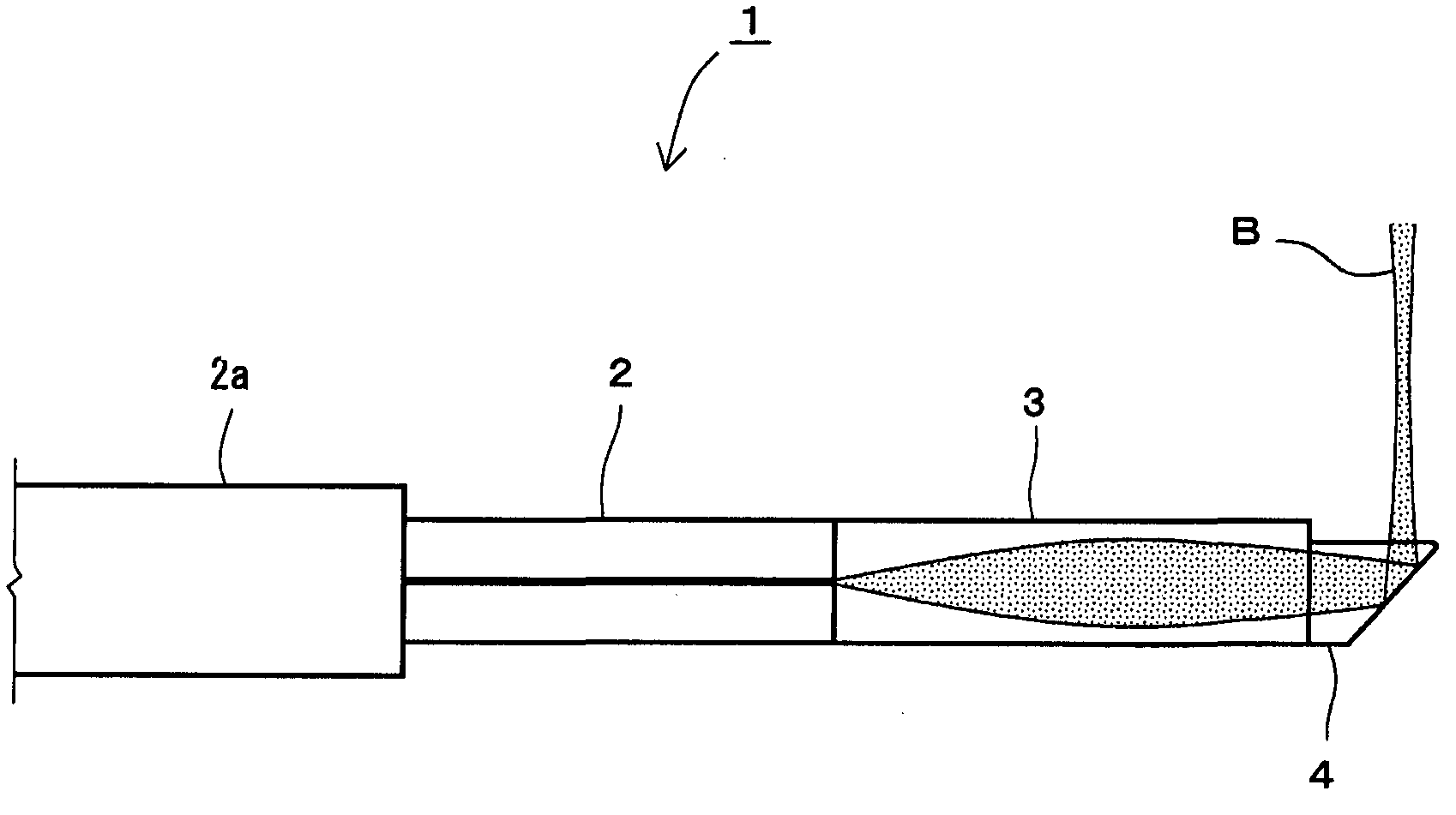

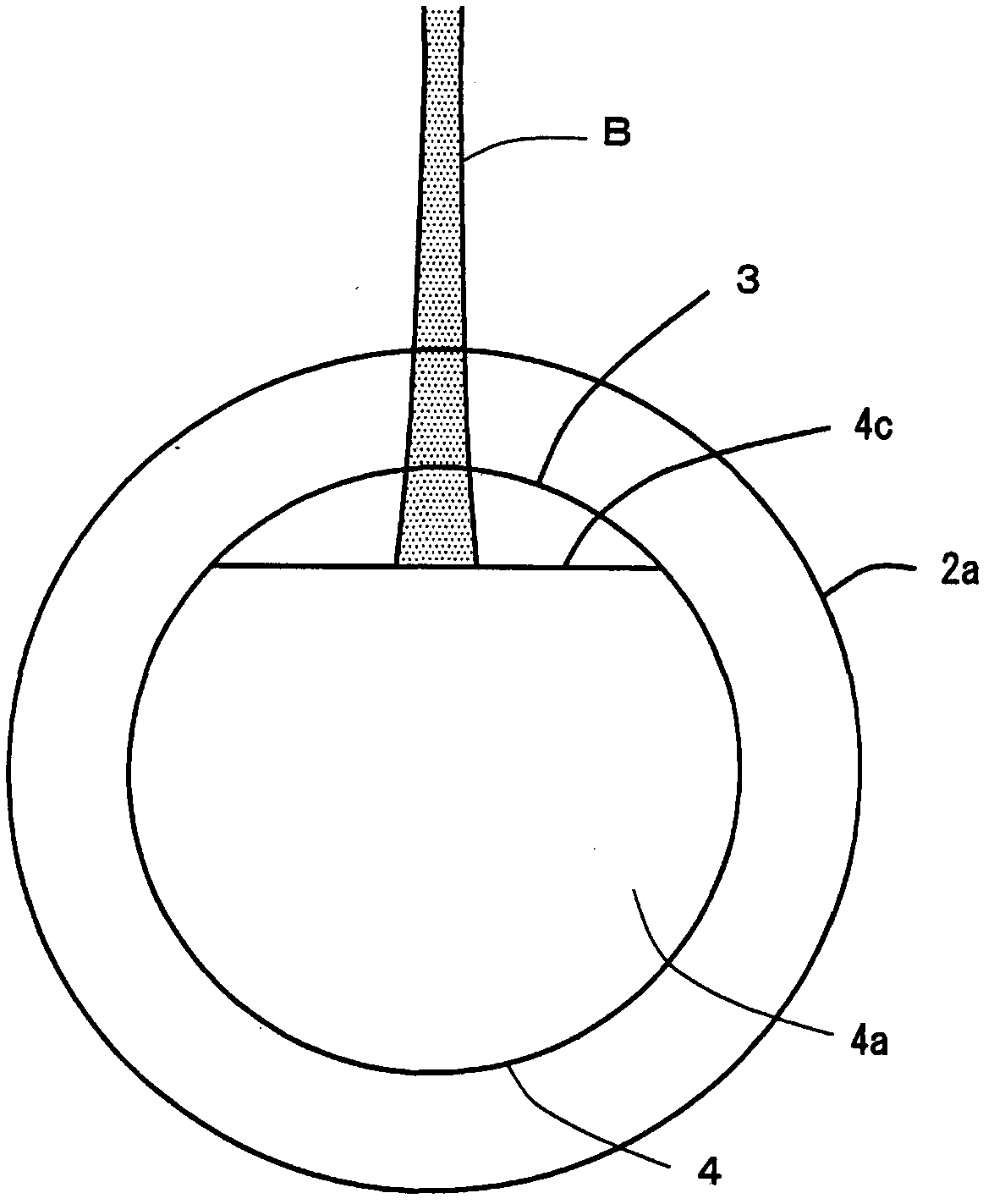

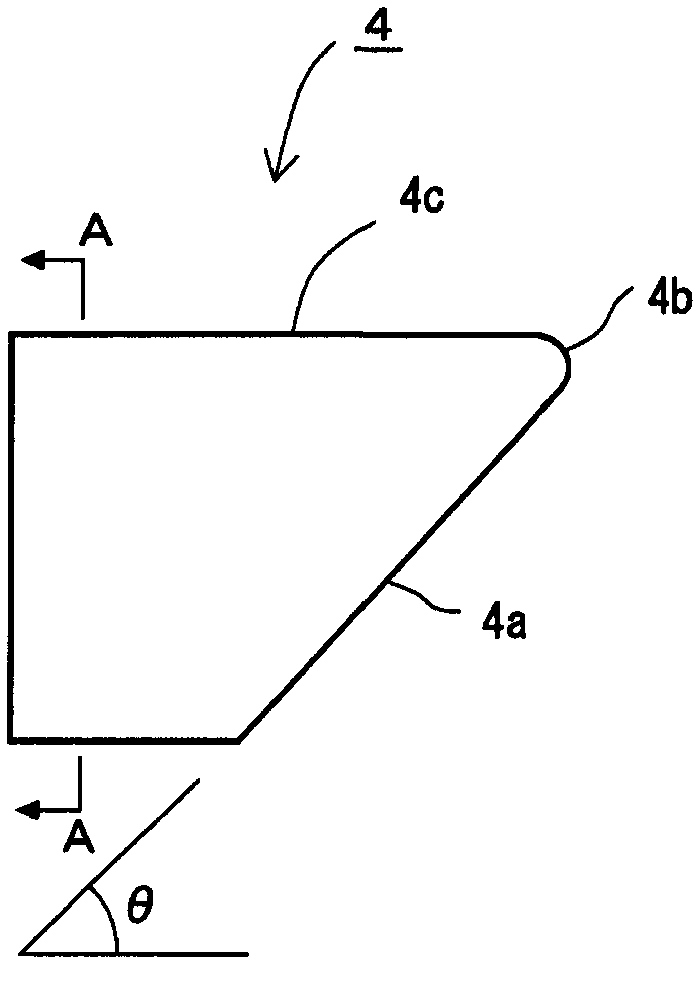

[0084] Figure 1~4 The side injection device 1 related to the embodiment, figure 1 is the side view, figure 2 is the front view, image 3 is the enlarged side view of prism 4, Figure 4 yes image 3 The A-A line profile.

[0085] The side emission device 1 is composed of an optical fiber 2 , a rod lens 3 , and a prism 4 .

[0086] The optical fiber 2 is a single-mode optical fiber with an outer diameter of 125 μm, and the coating portion 2 a at the front end is removed, and the rod lens 3 is welded to the front end.

[0087] The rod lens 3 is a GRIN lens with an outer diameter of 125 μm made of quartz glass, and the axes of the optical fiber 2 and the rod lens 3 are automatically aligned by the self-alignment effect during welding.

[0088] The prism 4 is quartz glass, and a part of the outer circumference of a cylinder with a diameter of d=125 μm is cut off for g=11 μm, and the remaining h=114 μm to form the basic shape of a planar exit surface 4c parallel to the axis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com