Speed reducer having function of stepless speed regulation

A technology of stepless speed regulation and reducer, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., and can solve the problems of high technical requirements of on-site maintenance engineers, poor reliability of high-voltage frequency converters, and harmonic interference control engineers. Trouble and other problems, to achieve the effect of improving speed regulation accuracy and speed regulation stability, easy manufacturing and installation, and solving shaft end sealing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

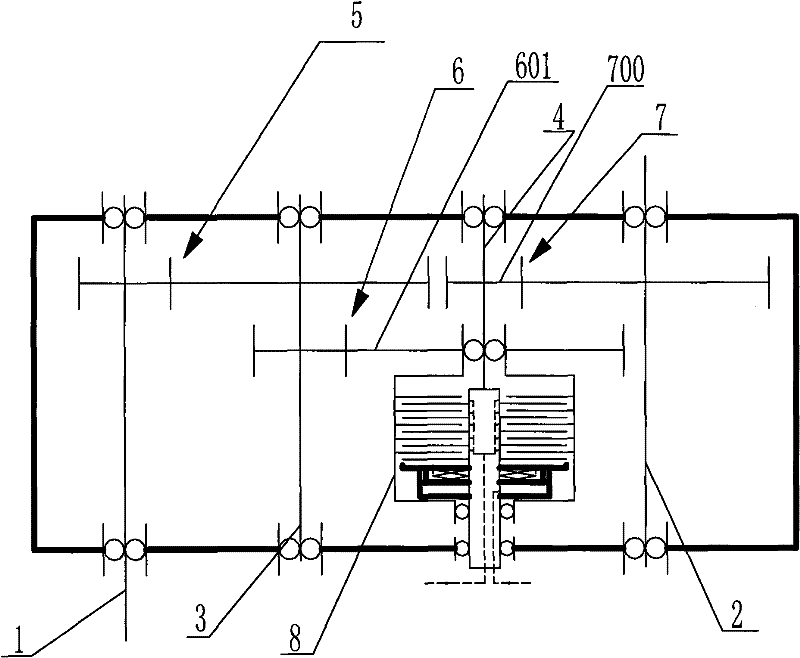

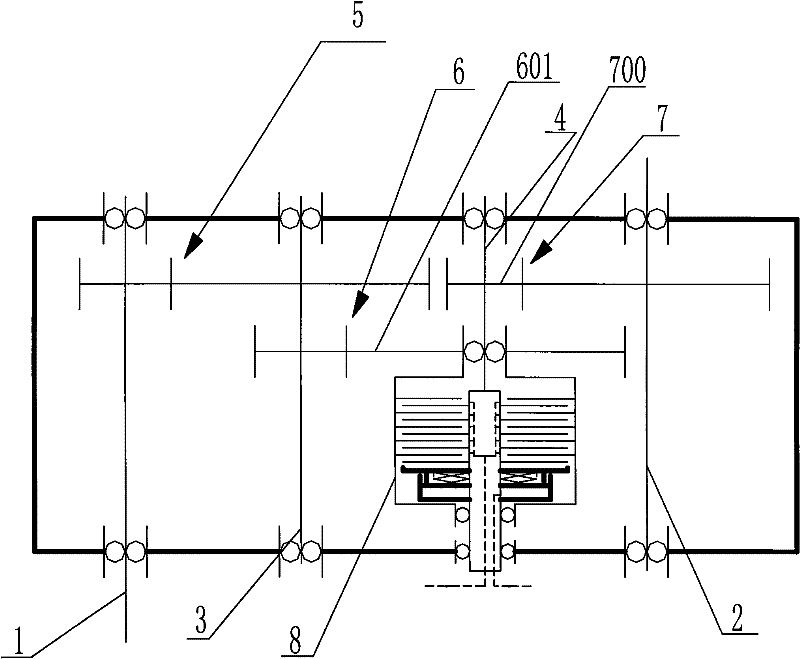

[0026] combine figure 1 , a reducer with stepless speed regulation function, including a casing, a high-speed input shaft 1 and a load output shaft 2, the axis line of the high-speed input shaft 1 and the axis line of the load output shaft 2 are arranged parallel to each other. Between the high-speed input shaft 1 and the load output shaft 2, the No. 1 intermediate transition shaft 3 and the No. 2 intermediate transition shaft 4 are sequentially arranged, and the axes of the No. 1 intermediate transition shaft 3 and the No. 2 intermediate transition shaft 4 are also connected The axis lines of 1 are arranged parallel to each other. The high-speed input shaft and the No. 1 intermediate transition shaft are connected through the first reduction gear pair 5, the No. 1 intermediate transition shaft 3 and the No. 2 intermediate transition shaft 4 are connected through the second reduction gear pair 6, and the No. 2 intermediate transition shaft The shaft 4 is connected to the load...

Embodiment 2

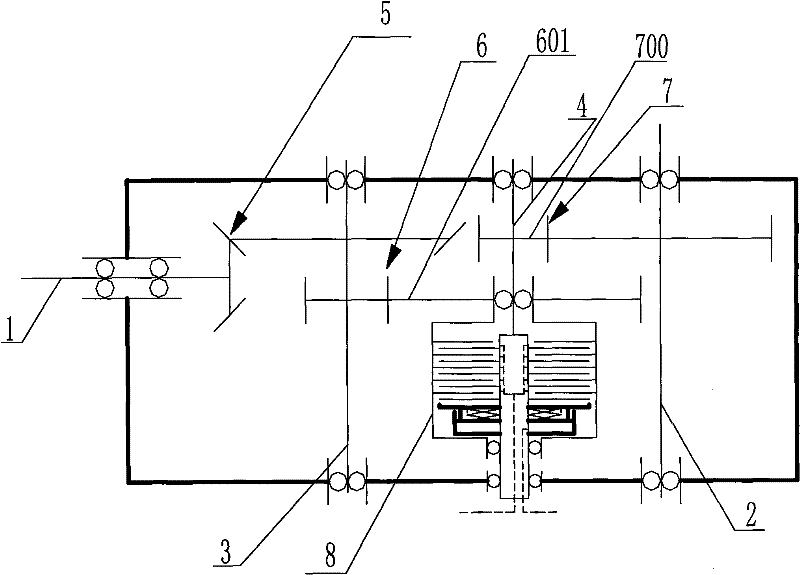

[0028] combine figure 2 , a reducer with stepless speed regulation function, including a casing, a high-speed input shaft 1 and a load output shaft 2, the axis line of the high-speed input shaft 1 and the axis line of the load output shaft 2 are arranged perpendicular to each other. Between the high-speed input shaft 1 and the load output shaft 2, the No.1 intermediate transition shaft 3 and the No. The axis lines are arranged parallel to each other. The high-speed input shaft and the No. 1 intermediate transition shaft are connected through the first reduction gear pair 5 (bevel gear pair), and the No. 1 intermediate transition shaft 3 and the No. 2 intermediate transition shaft 4 are connected through the second reduction gear pair 6 The second intermediate transition shaft 4 is connected to the load output shaft 2 through the third reduction gear pair 7 , and an oil film clutch 8 is arranged on the second intermediate transition shaft 4 . If the intermediate transition s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com