Intermittent drying system and method of multifunctional fluidized bed for freezing, spraying and pelleting

A freezing spray and drying system technology, applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of limited functions, high investment cost, inflexible operation, etc., to reduce quality degradation, mixed distribution Uniform, widely applicable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

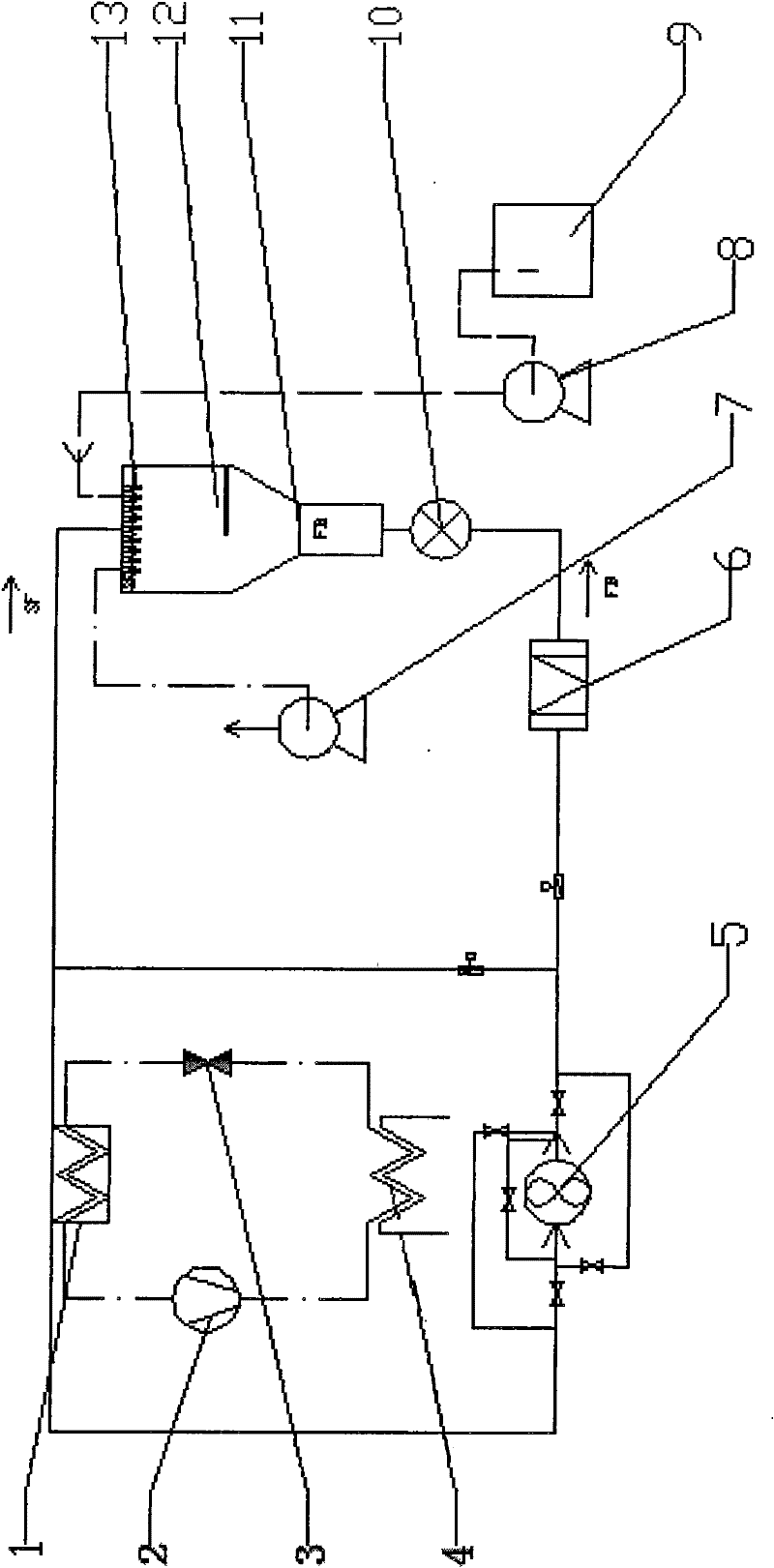

[0057] First method of the present invention is:

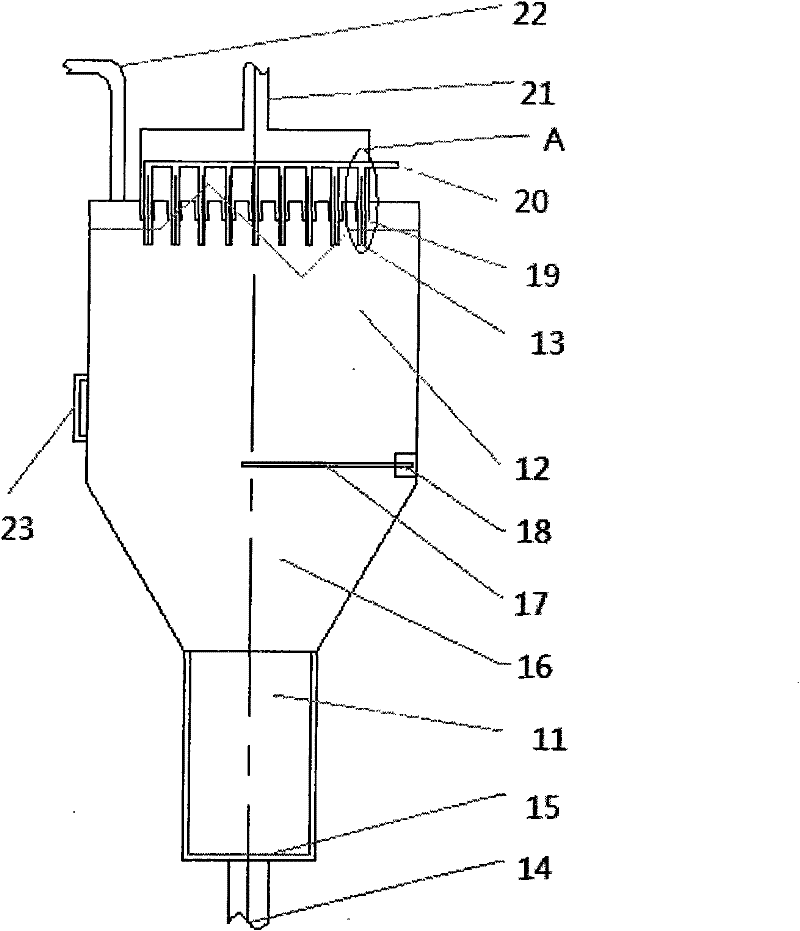

[0058] 1) Turn on the vacuum pump 7 to form the vacuum environment of the closed-loop system, and the vacuum degree is 0.01MPa. Then turn on the heat pump evaporator 1, heat pump compressor 2, heat pump throttle valve 3, heat pump condenser 4, fan and wind direction reversing device 5, and the cold air enters from the top of the drying chamber 12, reducing the overall temperature in the system to -50°C to -60°C; (The temperature can also be -53°C or -55°C or -58°C)

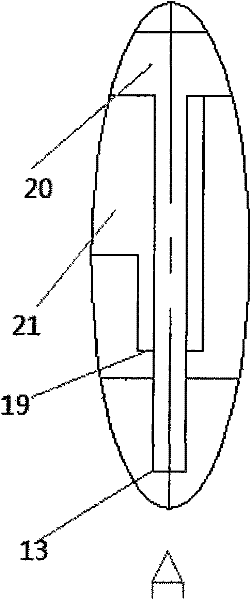

[0059] 2) Turn on the metering pump 8, use the atomizer 13 to atomize the solution into fine mist droplets, and the freezing medium around the atomizer: -50°C to -60°C (the temperature can also be -52°C or -54°C or - 58°C) low-temperature air or inert gas or one or more combinations of the following solvents: ethanol, toluene, methanol, n-butanol, tert-butanol, etc.; flow down with the mist droplets, and quickly freeze the mist droplets into fine particles Solid...

Embodiment 2

[0065] Second drying method of the present invention is:

[0066] 1) Turn on the heat pump evaporator 1, heat pump compressor 2, heat pump throttle valve 3, heat pump condenser 4, fan and wind direction reversing device 5, the cold air enters from the top of the drying chamber 12, and the overall temperature in the system is reduced to -50 °C to -60°C (the temperature can also be -53°C or -55°C or -58°C);

[0067] 2) Turn on the metering pump 8, use the atomizer 13 to atomize the solution into fine mist droplets, and the freezing medium around the atomizer: -50°C to -60°C (the temperature can also be -52°C or -54°C or - 58°C) low-temperature air or inert gas or organic solution (for example) flows down with the mist droplets, and the mist droplets are quickly frozen into fine solid particles, and the solid particles settle in the fluidization cylinder 11;

[0068] 3) After the set time (depending on the amount of material to be processed), when the solid particles in the flui...

Embodiment 3

[0073] The third drying method of the present invention is:

[0074] 1) The material to be dried is put into the fluidized cylinder 11 through the hand hole of the drying chamber 12, and the vacuum pump 7 is turned on to form a vacuum environment of a closed-loop system, and the vacuum degree is 0.01MPa. Then open electric heater 6, heat pump evaporator 1, heat pump compressor 2, heat pump throttle valve 3, heat pump condenser 4 and blower fan and wind direction reversing device 5;

[0075] 2) The low-temperature hot air of 60°C to 80°C (the temperature can also be 65°C or 70°C or 75°C) enters from the bottom of the drying chamber 12. When the low-temperature hot air passes through the wet material, it will take out the moisture in the material. Increase;

[0076] 3) When the hot air passes through the heat pump evaporator 1, the air is cooled to 0°C, the humid air reaches saturation, and the moisture in it condenses out to achieve the purpose of dehumidification, and then en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com