Calibration method of low-temperature temperature element

A low-temperature temperature and calibration method technology, applied in thermometer testing/calibration, thermometers, measuring devices, etc., can solve the problems of high experimental cost and small number of temperature-sensing elements, and achieve the goals of improving calibration efficiency, increasing the number of installations, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

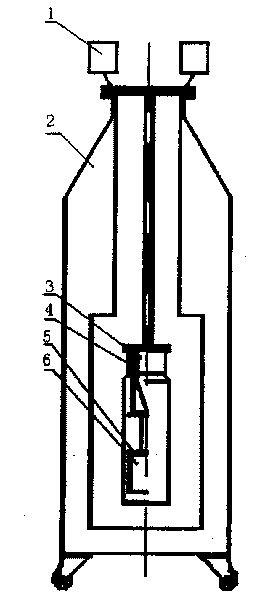

[0034] A kind of cryogenic temperature element calibration method of the present invention is introduced below in conjunction with accompanying drawing and embodiment:

[0035] like image 3 As shown, a low temperature temperature element calibration method mainly includes the following steps:

[0036] (1) Connect the temperature sensing element

[0037] According to the low temperature element calibration specification, install the standard sleeve platinum resistance thermometer and the temperature sensing element into the thermostatic copper block of the low temperature thermostat; the specific steps are as follows:

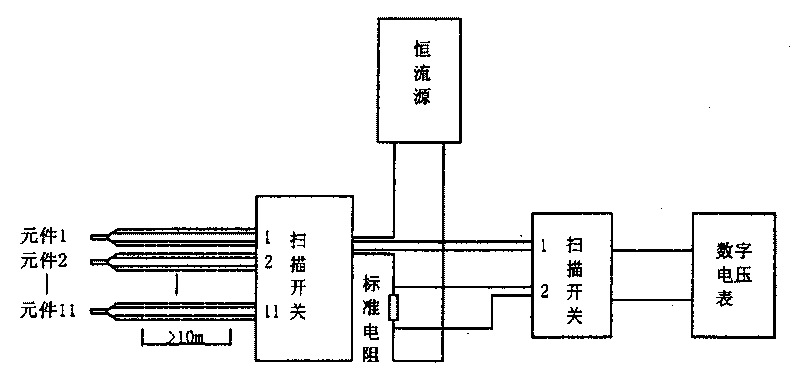

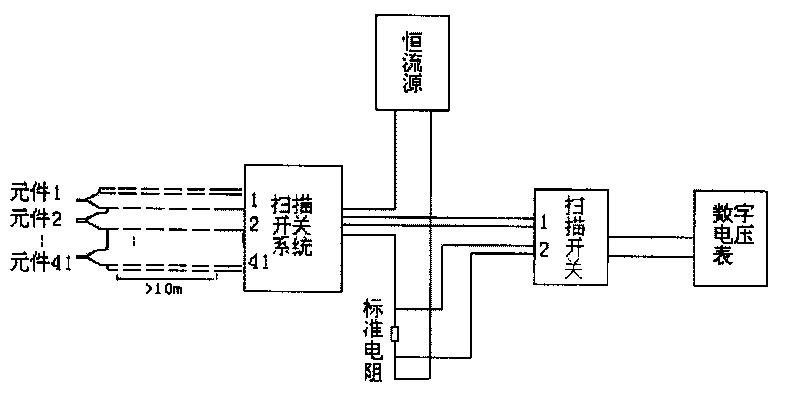

[0038] The temperature sensing element is connected to the constant temperature copper block terminal of the low temperature thermostat through 2 pins. There are 48 constant temperature copper block terminals in total. Thermometer connection terminals;

[0039] One pin of temperature sensing element 1 is connected to terminal 1 and terminal 2, the other pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com