System for monitoring auxiliary engine state

A technology of equipment status and monitoring system, applied in the field of measurement and control systems, can solve problems such as labor-intensive, difficult to ensure the reliability of industrial field equipment, equipment maintenance, and increase labor costs, so as to avoid data loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

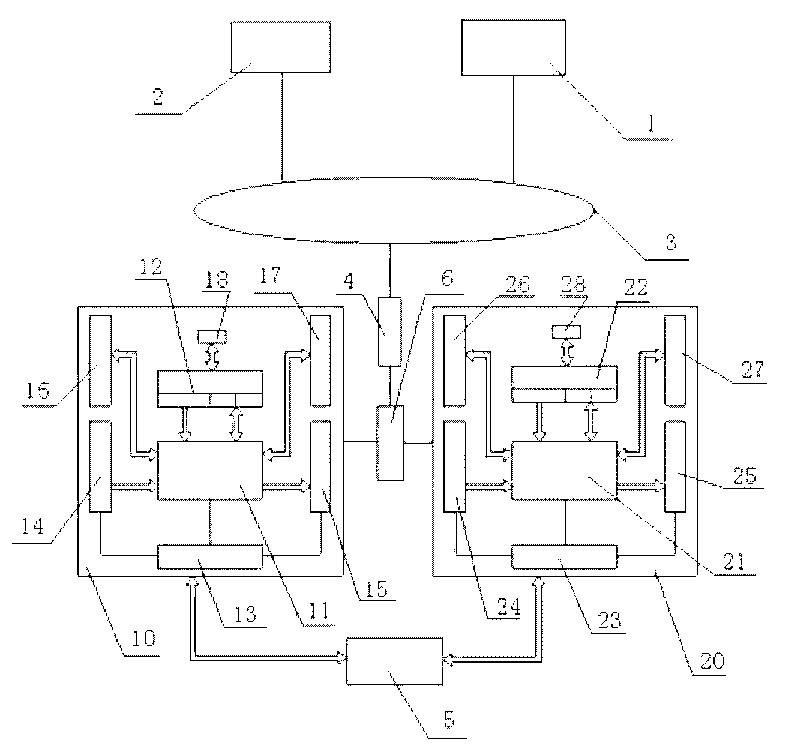

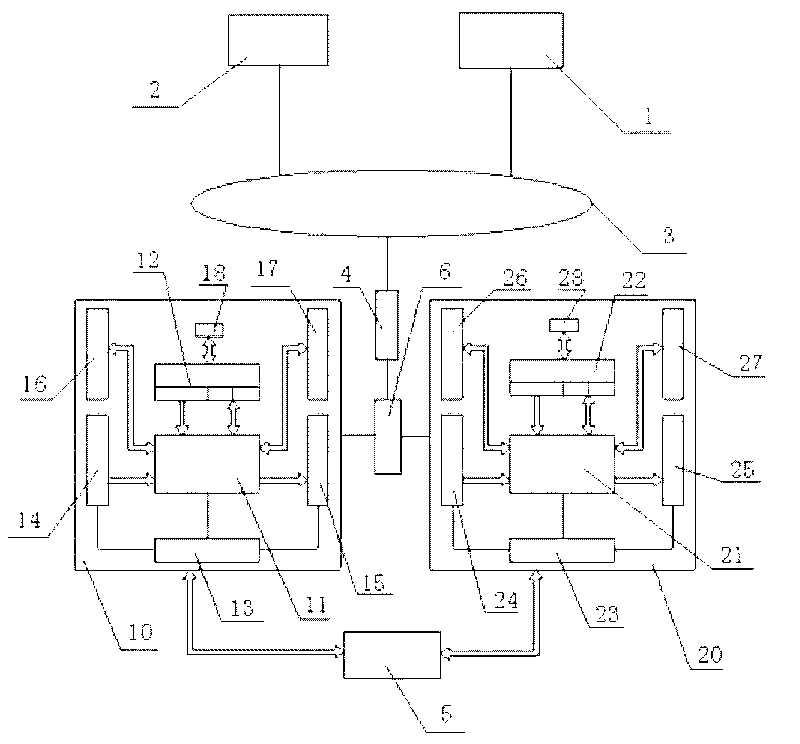

[0014] Embodiment one: if figure 1 As shown, a state monitoring system for auxiliary equipment includes: a computer 1, a data server 2, an Ethernet 3, a network switch 4, an active / standby switching device 6, a first programmable controller 10 and a second programmable controller 20 , both the first programmable controller 10 and the second programmable controller 20 are connected with the main / standby switching device 6, the main / standby switching device 6 is connected to the Ethernet 3 through the network switch 4, and is connected to the computer 1 and the computer connected to the Ethernet 3 The data server 2 is connected, and both the first programmable controller 10 and the second programmable controller 20 are connected with the industrial field auxiliary equipment 5 .

[0015] Because the main-standby switching device 6 has multiple serial ports and Ethernet ports, it is connected with two sets of programmable controllers with serial ports and Ethernet ports respective...

Embodiment 2

[0040] Embodiment 2: The difference from Embodiment 1 is that there is no active-standby switching device 6 as one of the hardware in the system, the first programmable controller and the second programmable controller are connected to the network switch, and are connected to the Ethernet through the network switch , to connect with computer and data server. The active / standby switching of two sets of programmable controllers is realized through logic programs in the two sets of programmable controllers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com