Electrostatic capacitance coupling type touch panel

A technology of electrostatic capacitance and coupling method, which is applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of overall thickness, surface static electricity is difficult to change, and position cannot be detected, etc., and achieves the effect of excellent display performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

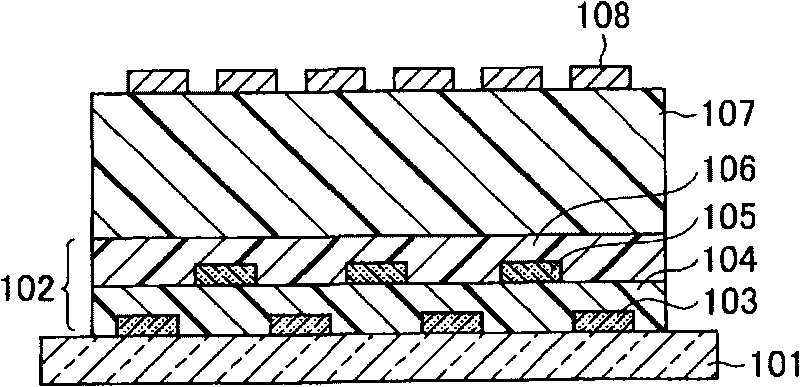

[0067] Made with the following conditions figure 1 The touch screen device of Embodiment 1 shown in the sectional view of FIG.

[0068] In the touch screen device of this embodiment, a coordinate detection circuit layer 102 for detecting position coordinates is formed on one side of a transparent substrate 101 . In this circuit layer, transparent electrodes serving as coordinate electrodes 103 and 105 are arranged via insulating films 104 and 106 .

[0069] As the transparent substrate 101, a glass substrate such as alkali glass such as soda glass or borosilicate glass, non-alkali glass, or chemically strengthened glass is suitable. In addition, transparent polyethylene terephthalate films, polyester films such as polyethylene naphthalate, and polyimide films with high heat resistance and transparency are also known, and such films can also be used. Transparent resin substrate.

[0070] As the transparent electrodes serving as the coordinate electrodes 103 and 105 , oxide t...

Embodiment 2

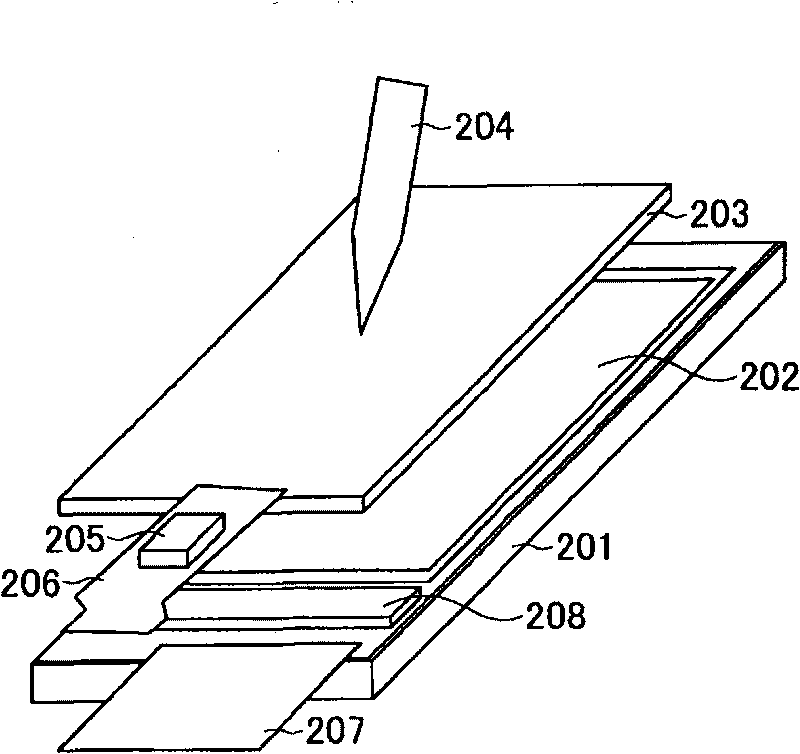

[0096] Made with the following conditions figure 2 The liquid crystal display device with a touch screen of the shown embodiment 2.

[0097] On the surface of the liquid crystal display device 201 facing the liquid crystal display area 202, it is superimposed and fixed on the first embodiment ( figure 1 ) obtained in the touch screen 203. The touch panel 203 is connected to a flexible printed wiring substrate 206 on which an IC 205 for controlling the position detection circuit of the touch panel is mounted. The flexible printed wiring board 206 connects the touch panel 203 and the liquid crystal display device 201 to input signals to the liquid crystal display device 201 . The liquid crystal display device 201 is mounted with a control IC 208 for liquid crystal display and connected to a flexible printed circuit board 207 . The flexible printed wiring board 207 plays a role of transmitting display image signals to the liquid crystal display device 201 by being connected t...

Embodiment 3

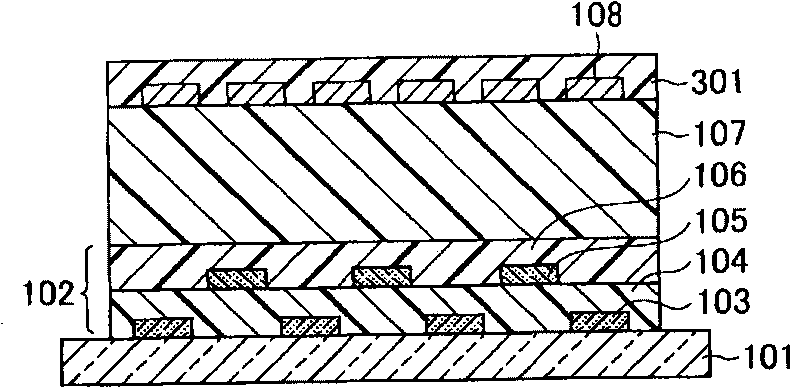

[0101] Made with the following conditions image 3 The touch screen device of Embodiment 3 is shown.

[0102] In Example 1 ( figure 1 ) formed a surface protection layer 301 on the outermost surface of the touch screen obtained in ).

[0103] As a material of the protective layer, the insulating film material having light transmission used in the insulating films 104 and 106 of Embodiment 1 is suitable.

[0104] In addition, not limited to the above-mentioned photosensitive materials, thermosetting materials obtained by combining acrylic resins, acrylic epoxy resins, and silicone resins as matrix polymers only with thermosetting materials are also suitable.

[0105] Furthermore, it can be bonded to a glass substrate such as alkali glass such as soda glass or borosilicate glass, non-alkali glass, or chemically strengthened glass, and used as the surface protection layer 301 . It can also be used with transparent resins such as transparent polyethylene terephthalate film, pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com