Apparatus and method for detecting contact position of robot

A contact position and robot technology, applied in the field of contact position devices, can solve the problems of low operation efficiency and large delay in contact position detection, and achieve the effect of efficient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

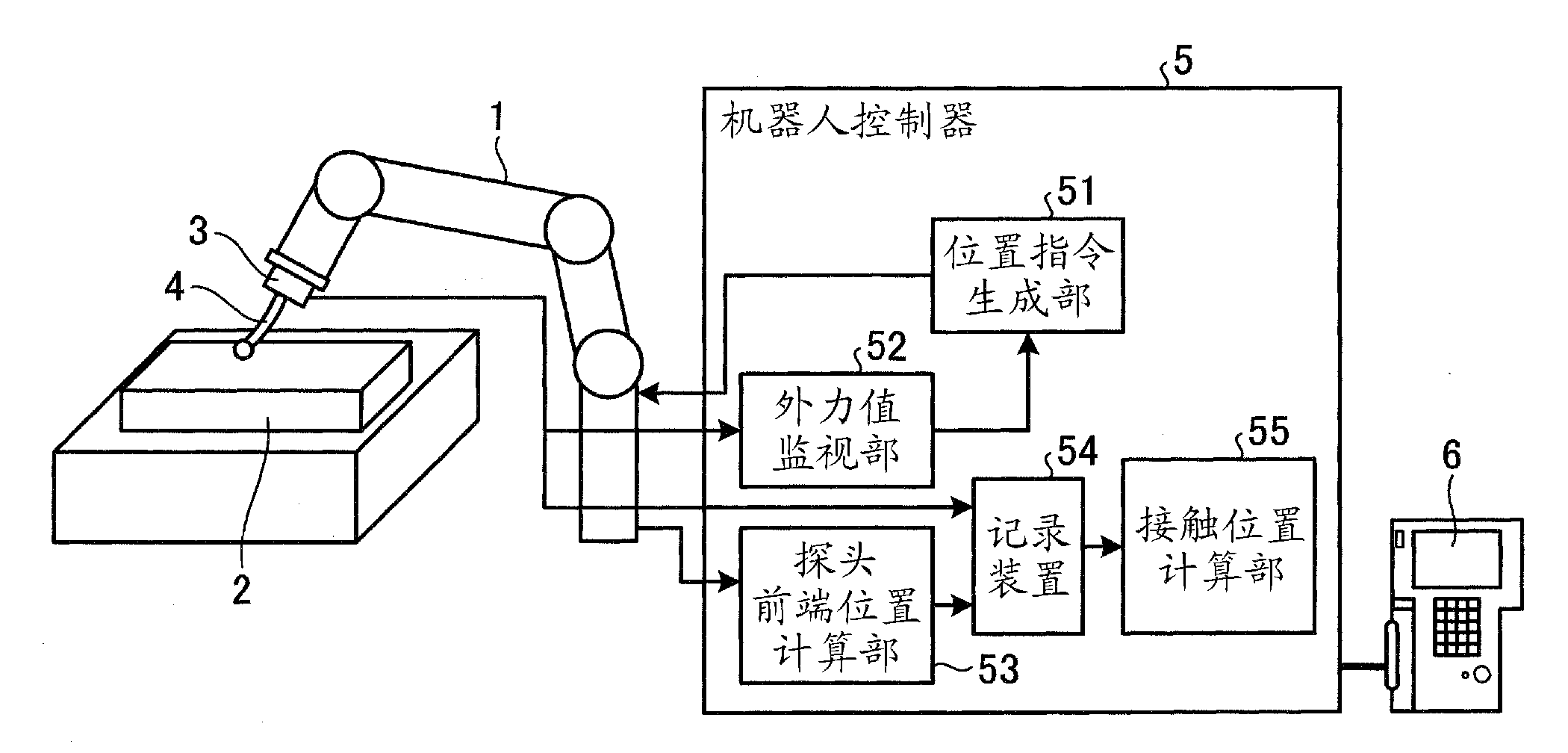

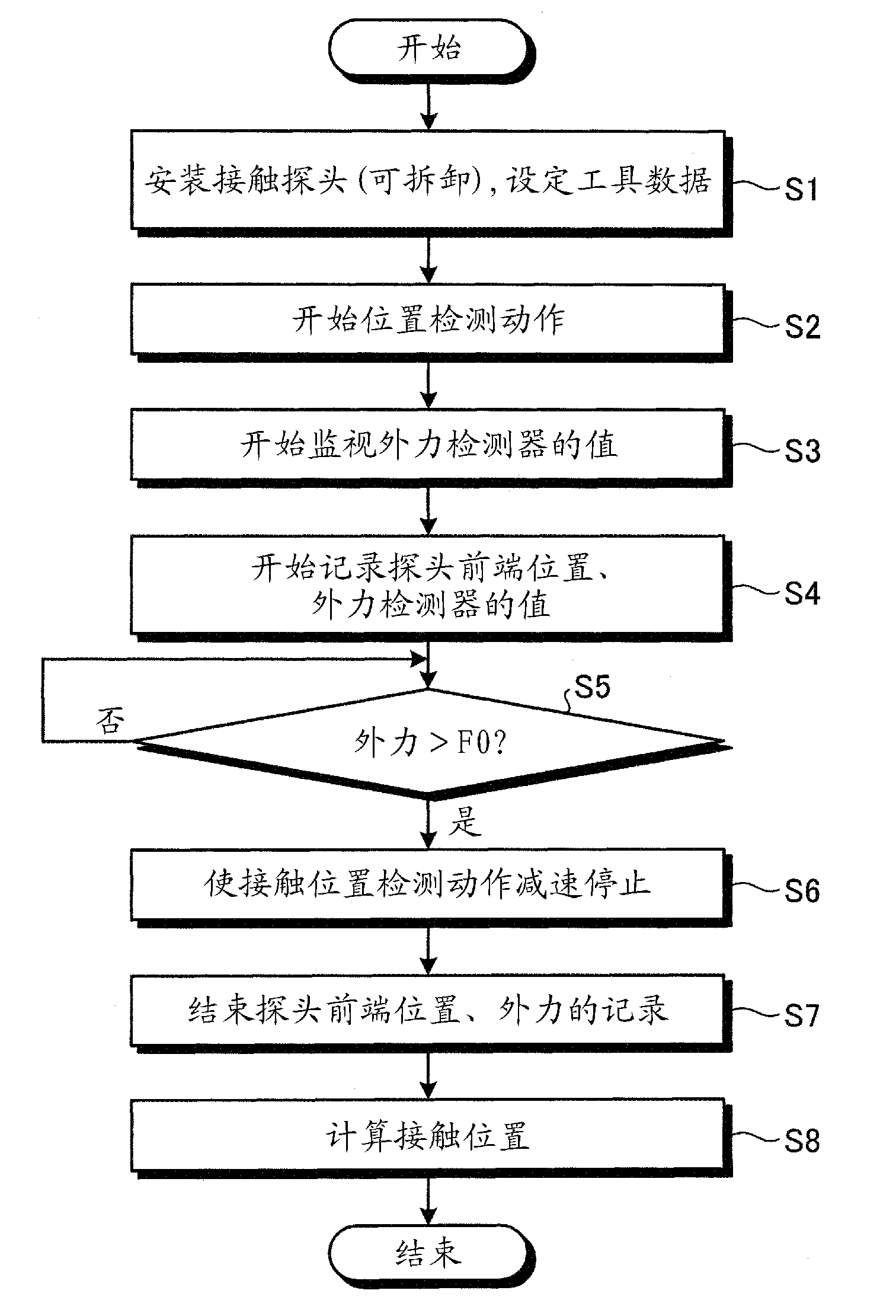

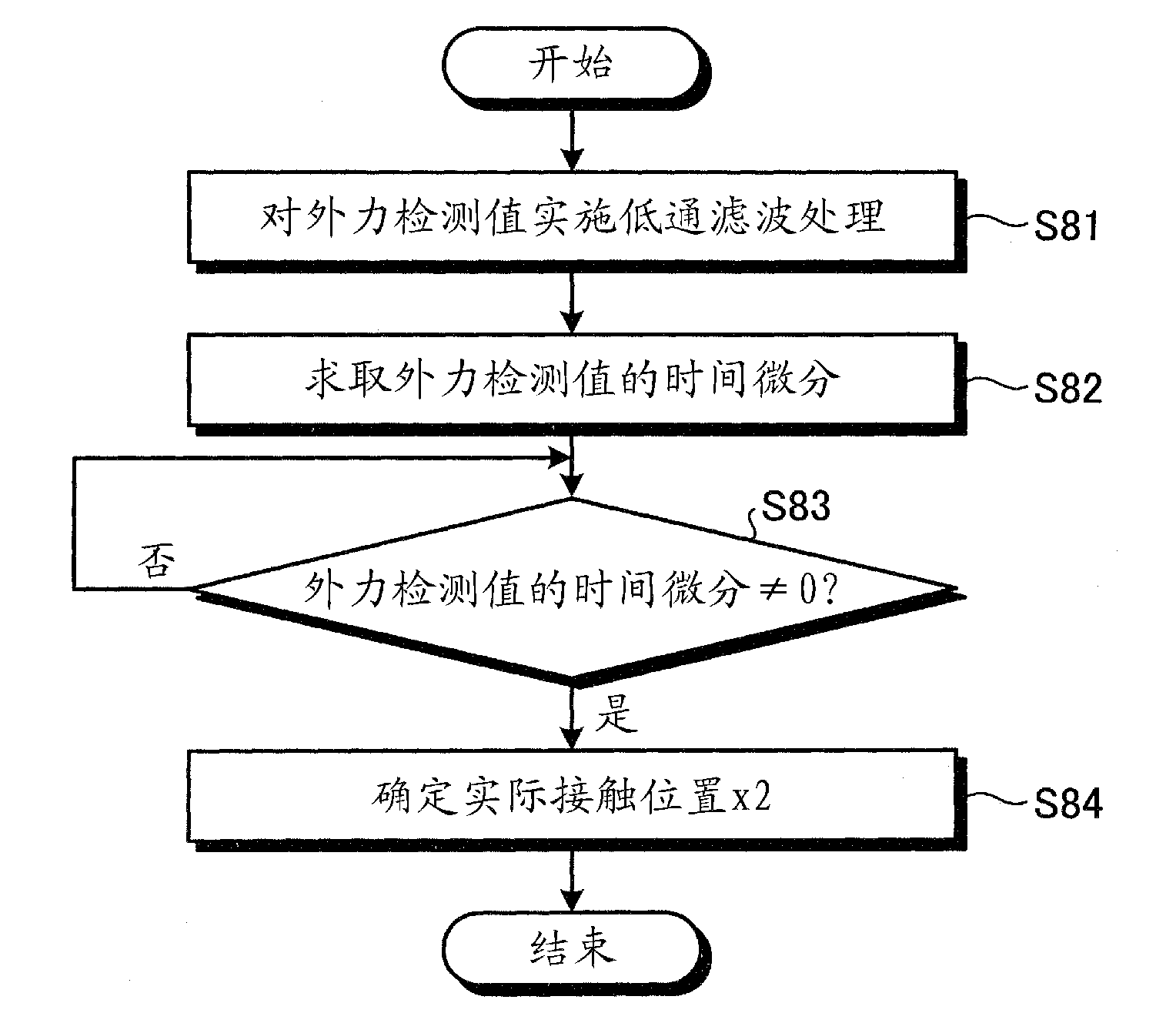

[0025] A device according to an embodiment is a device for detecting a contact position where a robot contacts an object, and includes a probe, a probe position calculation unit, a contact detection unit, and a contact position calculation unit. A probe is mounted on the robot capable of elastic displacement in the direction of contact with the object. The probe position calculation unit calculates the position of the probe with respect to the robot in operation. The contact detection unit detects a state in which the probe is in contact with an object. When the contact state of the probe is detected, the contact position calculation unit derives the contact position from the calculated position of the probe. Preferably, the device further includes a deceleration stop unit that decelerates and stops the robot when the contact state of the probe is detected.

[0026] The probe of the embodiment may have any structure as long as it can elastically displace in the direction in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com