Bearing system for printing press and printing press

A technology for printing machines and flexographic printing machines, applied in printing machines, general parts of printing machinery, rotary printing machines, etc., can solve problems such as adverse effects on printing quality and achieve high shape stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

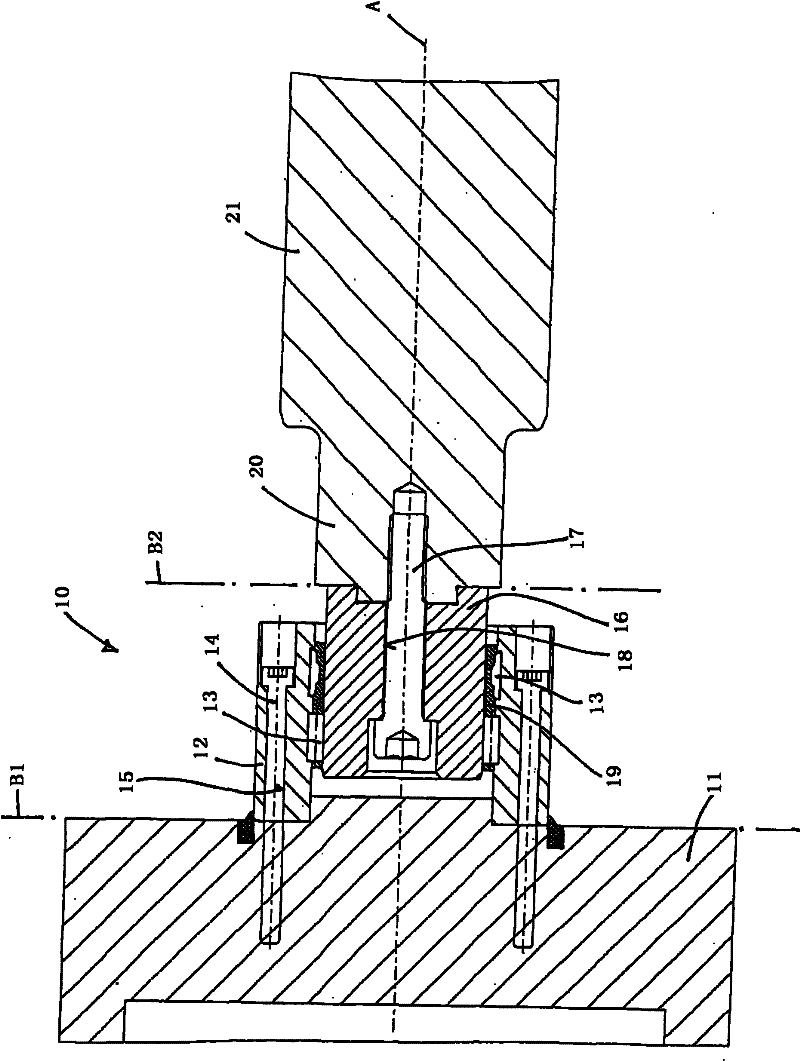

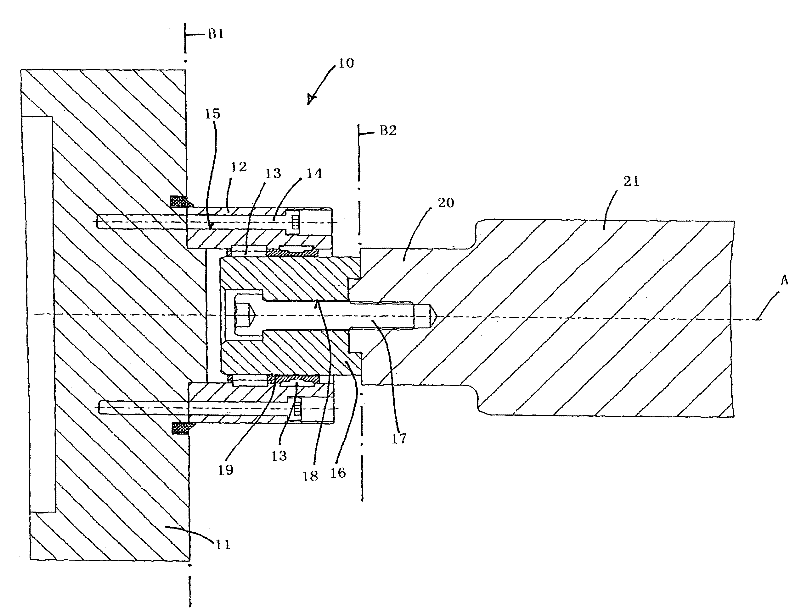

[0016] The shown bearing system 10 includes a bearing housing 11, and the outer ring 12 of the rolling bearing is flanged in the axial direction and connected to the bearing housing 11 on the fixed plane B1. Because the rolling bearing outer ring 12 is axially flanged on the bearing housing 11 , machining-induced tolerances of the components have no effect on the bearing play of the bearing system. Fixing screws 14 are provided for fixing the fixed bearing outer ring 12 to the bearing housing 11 . Boreholes 15 running parallel to the longitudinal axis A of the drum or roller are provided on the rolling bearing outer ring 12 at the same radial distance from the longitudinal axis A of the drum or roller to accommodate the fastening bolts 14 . However, based on the thick-walled structure, the outer ring has high shape stability. The outer ring 12 carries rolling bodies 13 guided by a retaining ring on the inner circumferential side, the rolling bodies 13 having a cylindrical des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com