Liquid metal-sliding bearing

A technology of liquid metal and sliding bearings, applied in bearings, bearing components, shafts and bearings, etc., can solve the problems of reduced performance of medical imaging systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

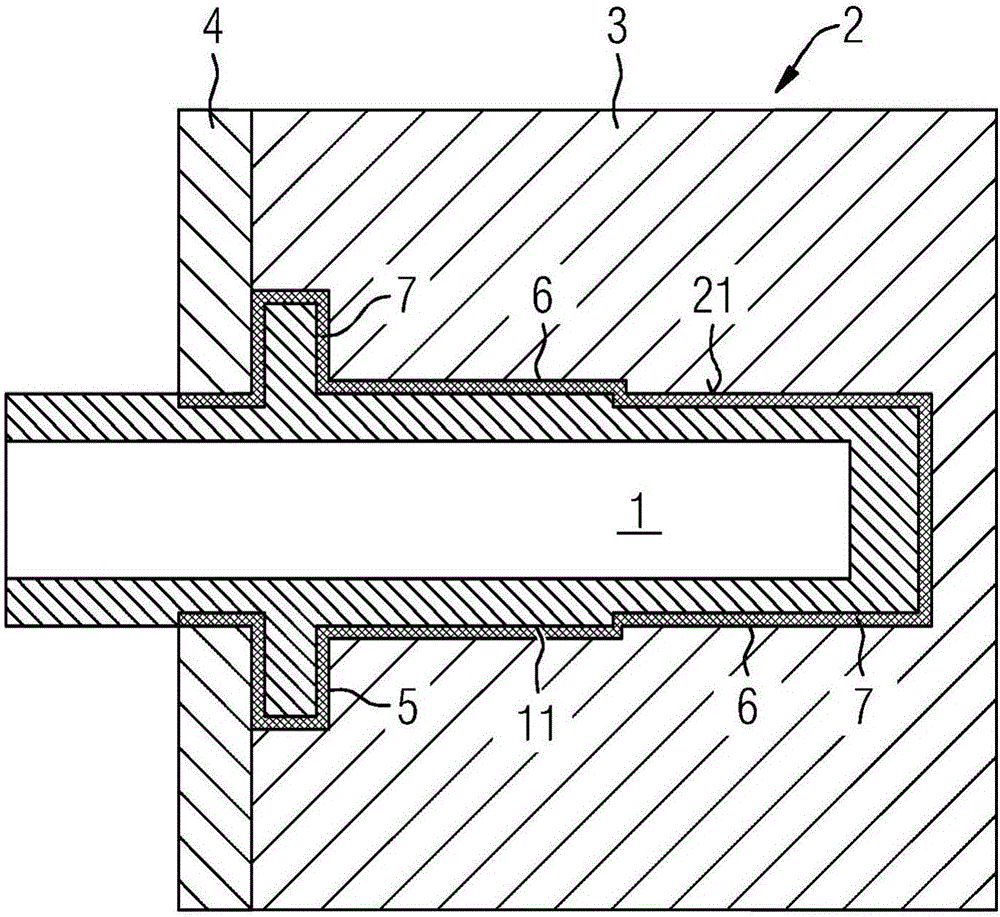

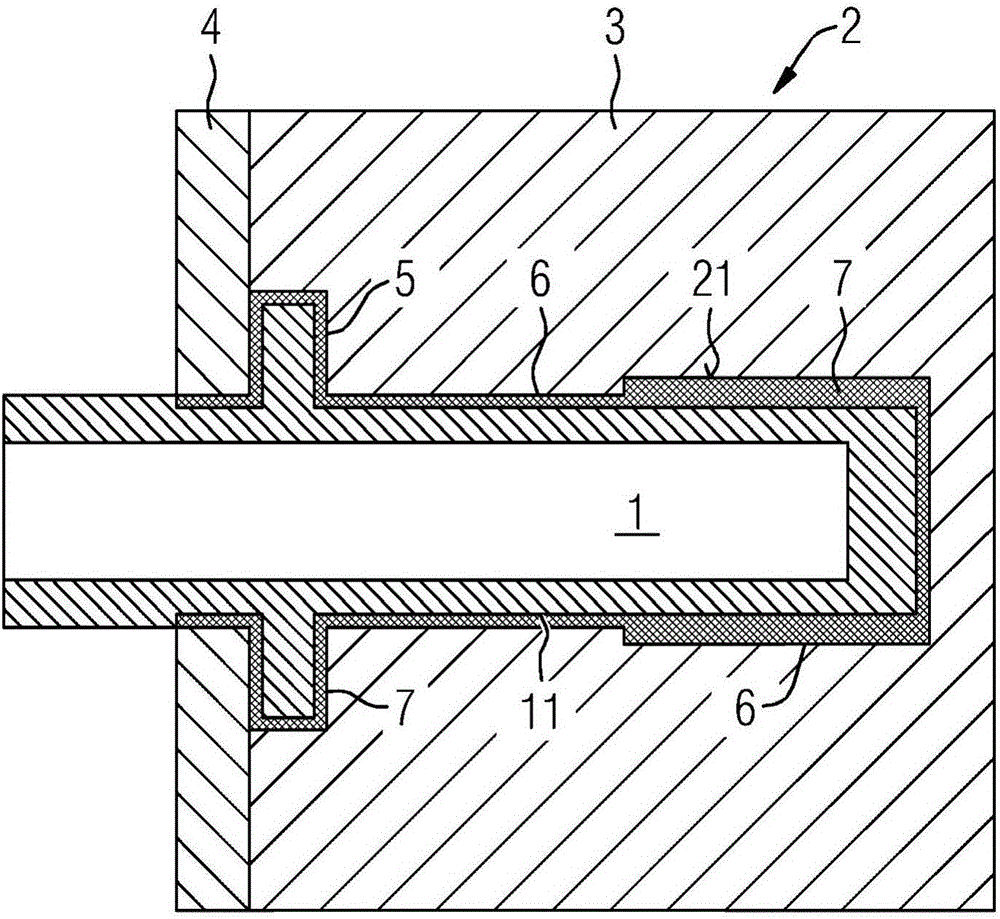

[0045] exist figure 1 and figure 2 The liquid metal plain bearing shown in has at least one first bearing part 1 with an outer diameter 11 and at least one second bearing part 2 with an inner diameter 21 .

[0046] The first bearing part 1 and the second bearing part 2 are produced, for example, from molybdenum.

[0047] The first bearing part 1 is designed as a stationary bearing part and forms an inner bearing, the opposite second bearing part 2 is designed as a rotating bearing part and comprises a first sleeve 3 and a second sleeve 4 which are locked against each other in a rotationally fixed manner. connect. The first sleeve 3 and the second sleeve 4 thus form a rotating bearing sleeve.

[0048] In the liquid metal-sliding bearing assembly, the inner bearing 1 (stationary bearing part) is arranged in the first sleeve 3 (part of the rotating bearing part 2) and afterward the second sleeve 4 (rotating bearing part 2 part) is connected to the first sleeve 3 in a torsion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com