Rigid contact net expansion joint

An expansion joint and rigid contact technology, applied in the direction of overhead lines, power rails, etc., can solve the problems of undisclosed pantograph smooth transition, copper braid failure, small joint compensation, etc., achieve good current-carrying performance and reduce use The effect of large quantity and compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

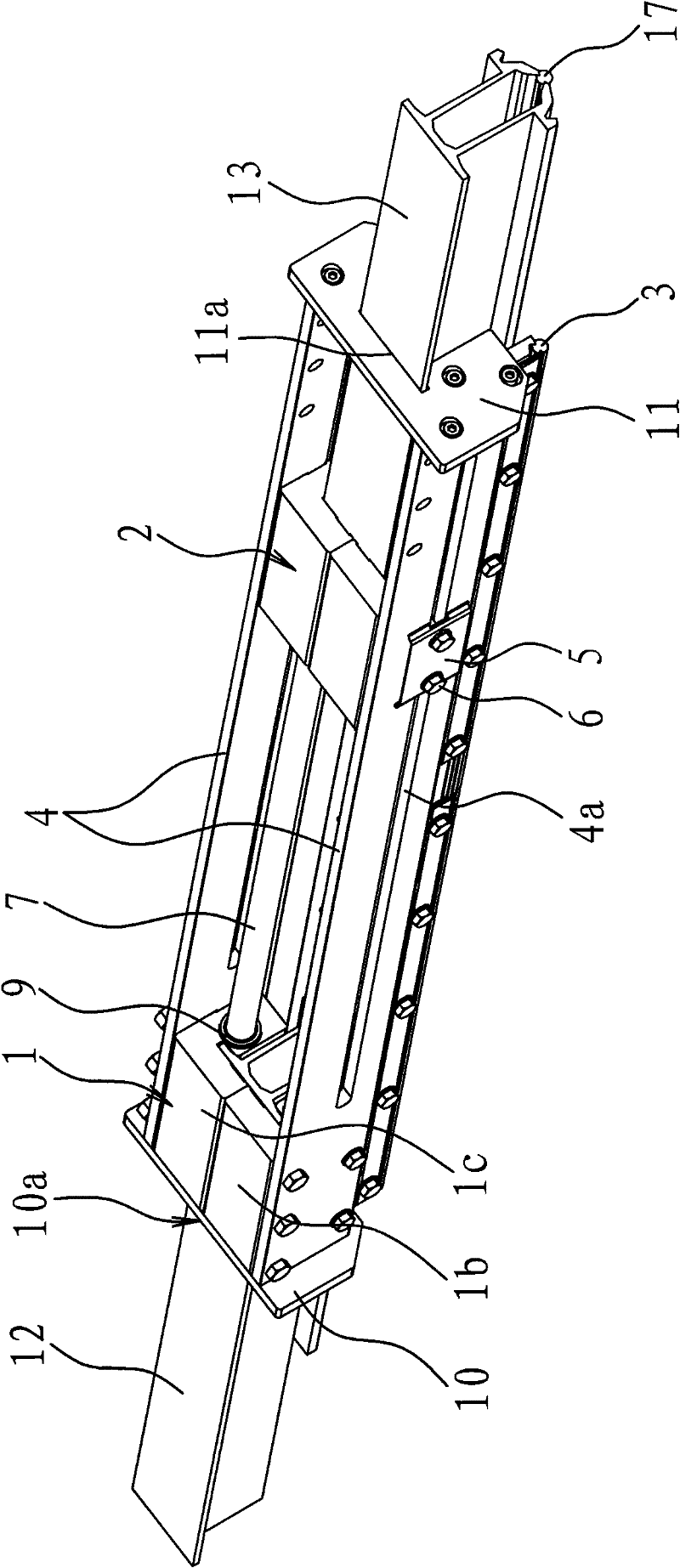

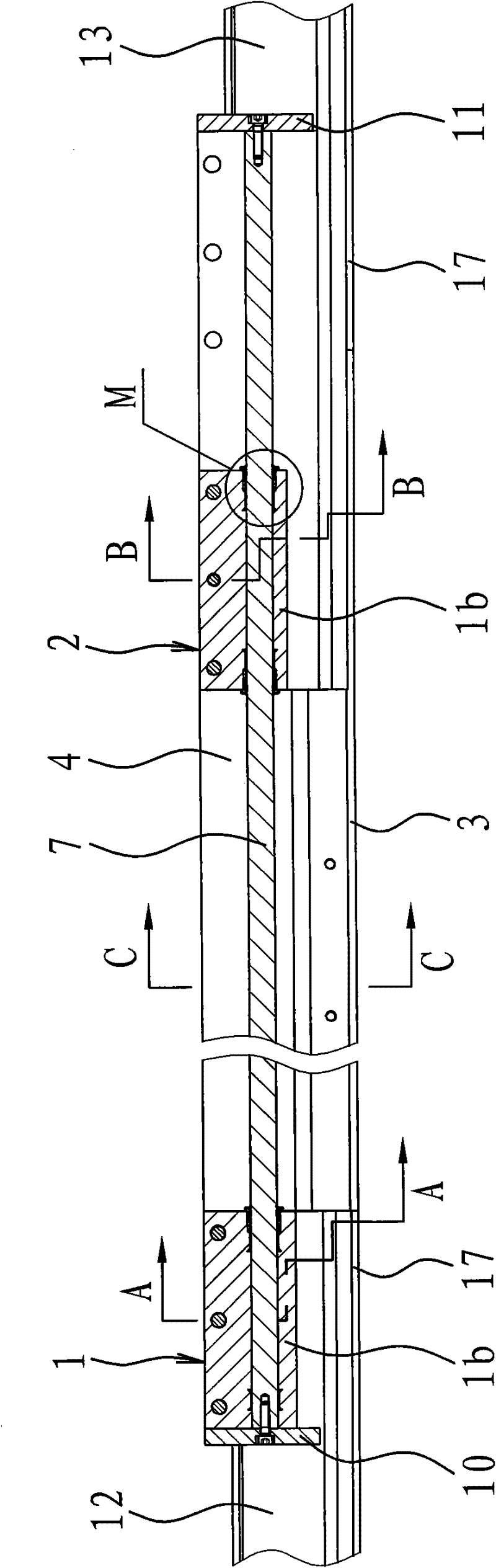

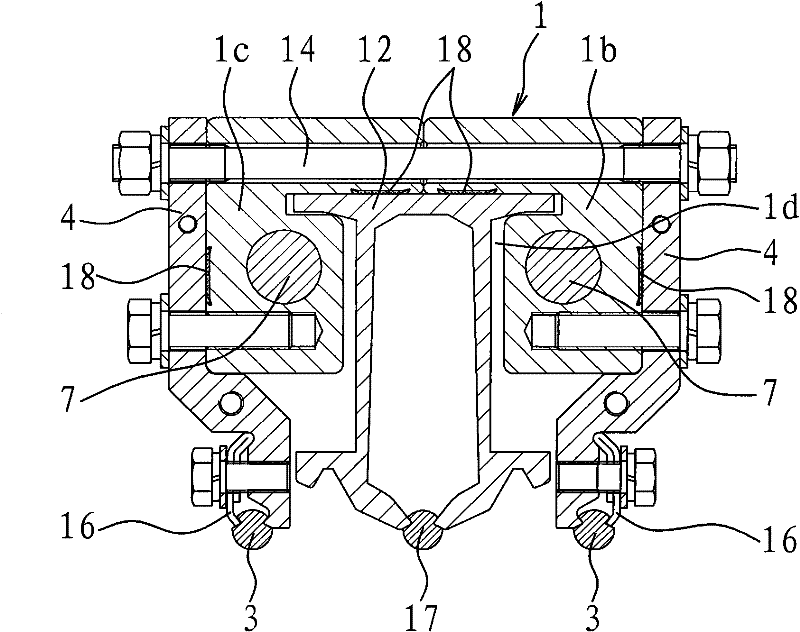

[0029] Such as figure 1 , figure 2 As shown, the rigid catenary expansion joint is connected to the busbars 12, 13, the busbars 12, 13 are fixed on the top of the tunnel through the suspension device, and the bottoms of the busbars 12, 13 are fixed with a contact wire 2 17. The specific structure of this joint includes The fixed joint 1 and the moving joint 2 capable of conducting electricity, the fixed joint 1 is fixed to the connecting end of the bus bar 12, the moving joint 2 is fixed to the connecting end of the bus bar 13, and there are two connecting joints between the fixed joint 1 and the moving joint 2. Or a guide member with electrical conductivity, the guide member includes two guide rails 1 and 4 in the shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com