Full trailer

A full trailer and frame technology, applied in the field of full trailers, can solve the problems of unsafe operation, easy to bruise hands, low efficiency, etc., and achieve the effect of safe and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

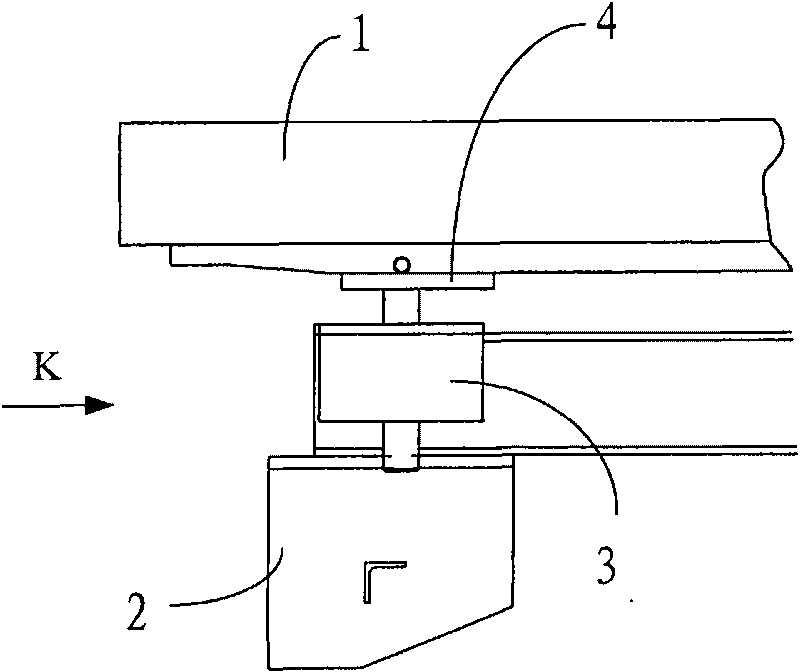

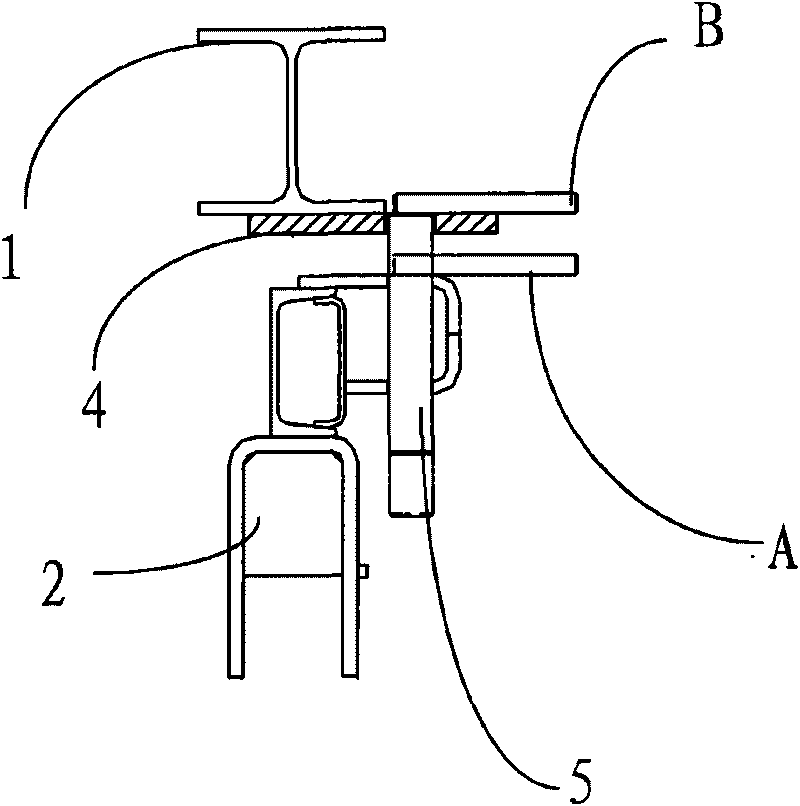

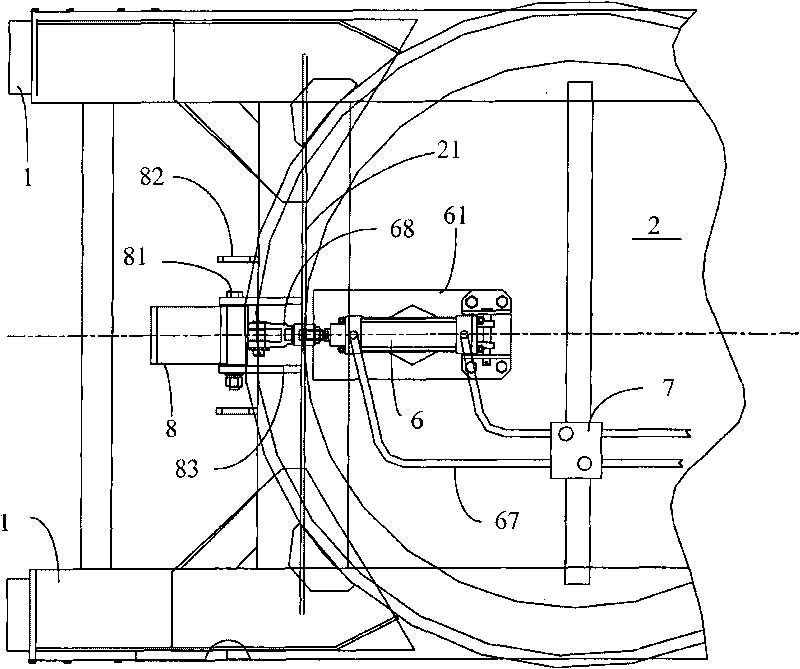

[0020] Figure 3 to Figure 6 It is the structure of the preferred embodiment of the present invention and the two different states of the baffle plate. The front end of the frame 1 of the trailer in this preferred embodiment is erected on the bogie 2 of the tractor. In order to realize safe and fast straight-line reversing, A fixed shaft 81 is arranged on the front side of the center position of the front beam 21 of the bogie 2. The middle part of the baffle plate 8 is hinged to the fixed shaft 81. The rear side of the center position of the crossbeam 21 is provided with a positioning device for clamping and accommodating the baffle plate 8 to prevent the vehicle frame 2 from freely rotating on the corresponding position of the front crossbeam 11 of the vehicle frame 1 and the baffle plate 8. Two positioning plates 82 on the front beam 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com