Jacketed asphalt heater and heating method

A heater and jacket type technology, applied in melting and processing tar asphalt/petroleum asphalt/natural asphalt, etc., can solve the problems of long heating time, low production efficiency, high heat loss, etc., and achieve less heat loss and high production efficiency , the effect of large heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the invention will be described in detail below in conjunction with the accompanying drawings, but the scope of protection of the present invention is not limited by the embodiments.

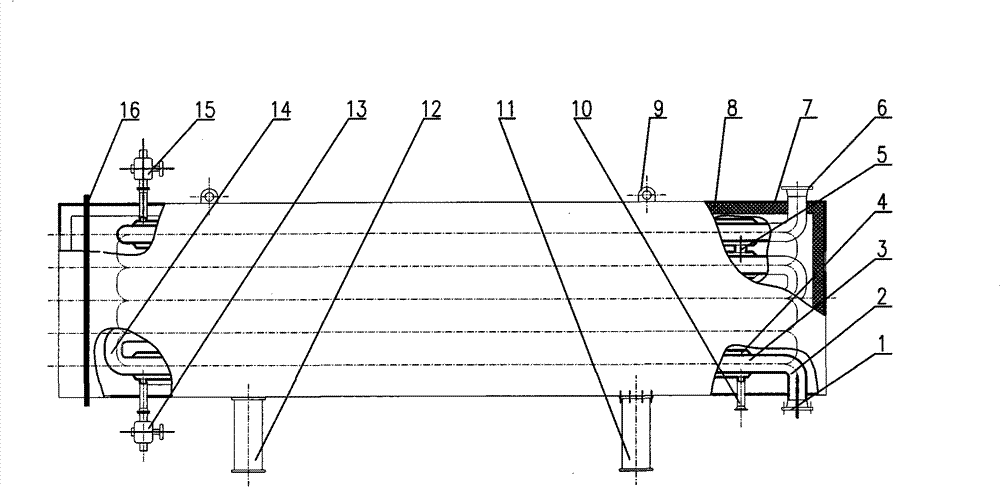

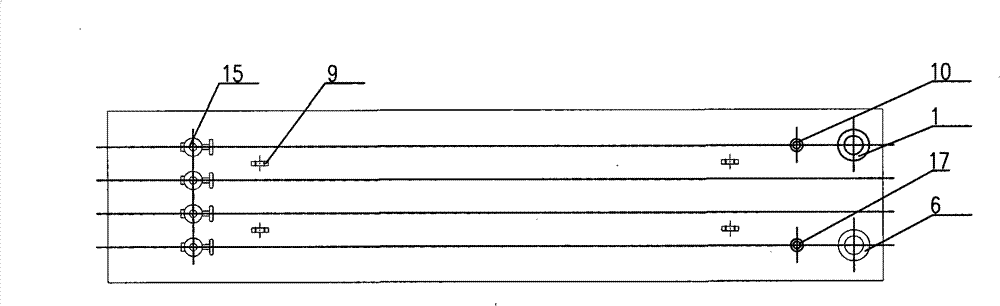

[0024] Such as Figure 1 to Figure 2 As shown, the jacketed asphalt heater of the present invention is composed of a heating device and an insulating device arranged outside the heating device.

[0025] The structure of the heating device is as follows: the asphalt inlet flange 1 is welded together with one end of the asphalt pipe 3 through the No. The asphalt outlet flange 6 is welded to form a serpentine asphalt conveying pipeline. The asphalt pipes 3 are arranged in 4 to 8 rows and 4 to 8 columns; the asphalt conveying pipeline is covered with a heat source casing 4 and a heat source connecting pipe 5 , the heat source sleeve 4 and the heat source connecting pipe 5 are staggeredly connected to form a heating chamber, the heat source sleeve 4 is welded outside the as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com