Dissimilar metal welding line ultrasonic creeping wave testing method

A technology of dissimilar metals and detection methods, applied in the field of ultrasonic detection, can solve the problems of inability to detect small opening cracks, missed inspections, and inability to determine the size of defects in the height direction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An ultrasonic creeping wave detection method for dissimilar metal welds, comprising the steps of:

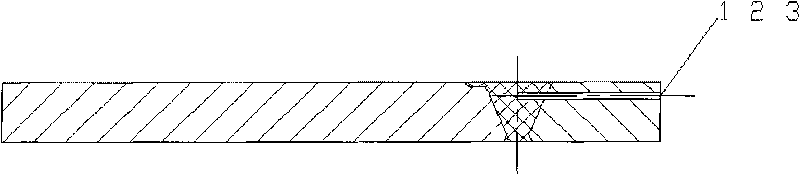

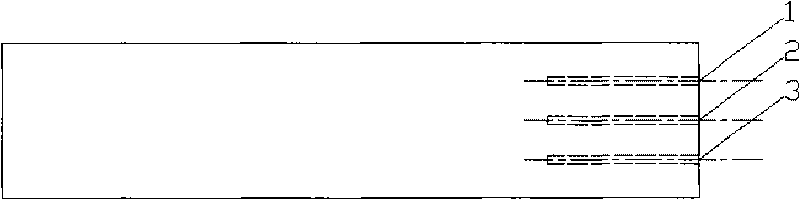

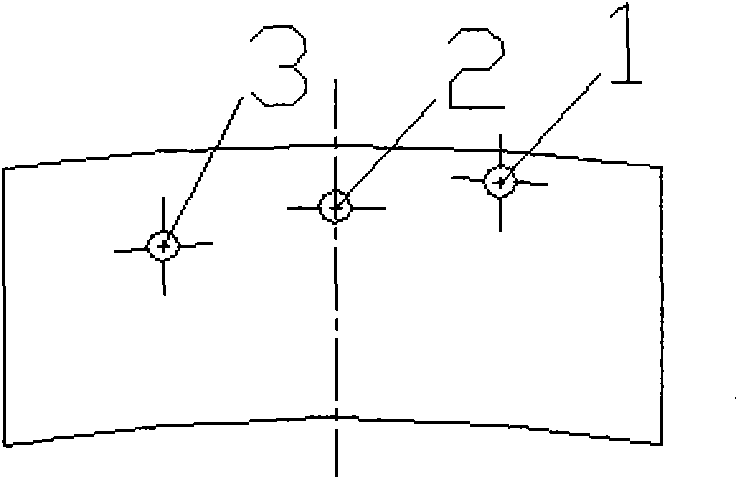

[0023] (1) Instrument depth measurement calibration

[0024] The depth measurement and calibration of the ultrasonic instrument is carried out by using the special depth measurement calibration test block. The ultrasonic instrument includes a creeping wave probe and a computer for data processing, and the creeping wave probe is a known creeping wave probe. Such as figure 1 , figure 2 , image 3 As shown, the special depth measurement calibration test block is a small section of the pipe along its axial direction. Three flat-bottomed holes at different depths from the circumferential surface are drilled on the top of the special depth measurement calibration test block. The three flat-bottomed holes are all parallel to the The pipe is axially drilled from the top of the test block to the centerline of the weld, and the diameter of the flat-bottomed hole is 2 mm. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com