Display device and method for manufacturing the same

A technology for a display device and a manufacturing method, which is applied in the manufacturing of semiconductor/solid-state devices, organic semiconductor devices, semiconductor devices, etc., can solve problems such as short circuits between lower electrodes and upper electrodes, and achieve the effect of preventing lighting failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, embodiments of the present invention will be described in detail in the order of the structure of a display device and its manufacturing method with reference to the accompanying drawings.

[0021] Structure of the display device of the first embodiment

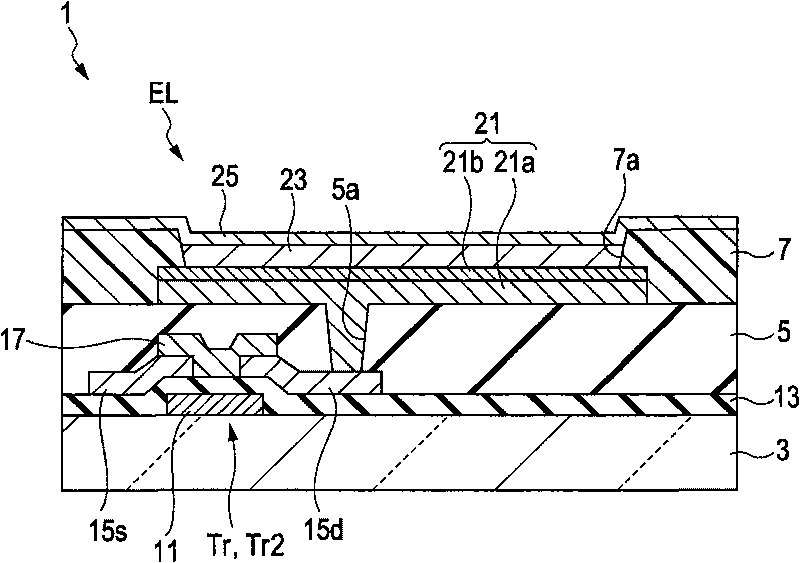

[0022] figure 1 is a cross-sectional view of the structure of one pixel of the display device according to the first embodiment. The display device 1 shown in this figure is an active matrix display device including an organic electroluminescence element EL, and is structured as follows.

[0023] Specifically, a thin film transistor Tr is provided in each pixel on the substrate 3 , and the thin film transistor Tr is covered with the interlayer insulating film 5 . A connection hole 5 a extending to the thin film transistor Tr is provided in the interlayer insulating film 5 . Further, in each pixel on the interlayer insulating film 5, an organic electroluminescence element EL connected to the thin film tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com