Energy-saving device for high-pressure discharge lamp

A technology for high-pressure discharge lamps and energy-saving devices, which is applied to lighting devices, electric light sources, and electrical components, and can solve the problems of increasing the burden on power adjustment components, suddenly extinguishing, and flickering, so as to prevent poor lighting, reduce burdens, and improve life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

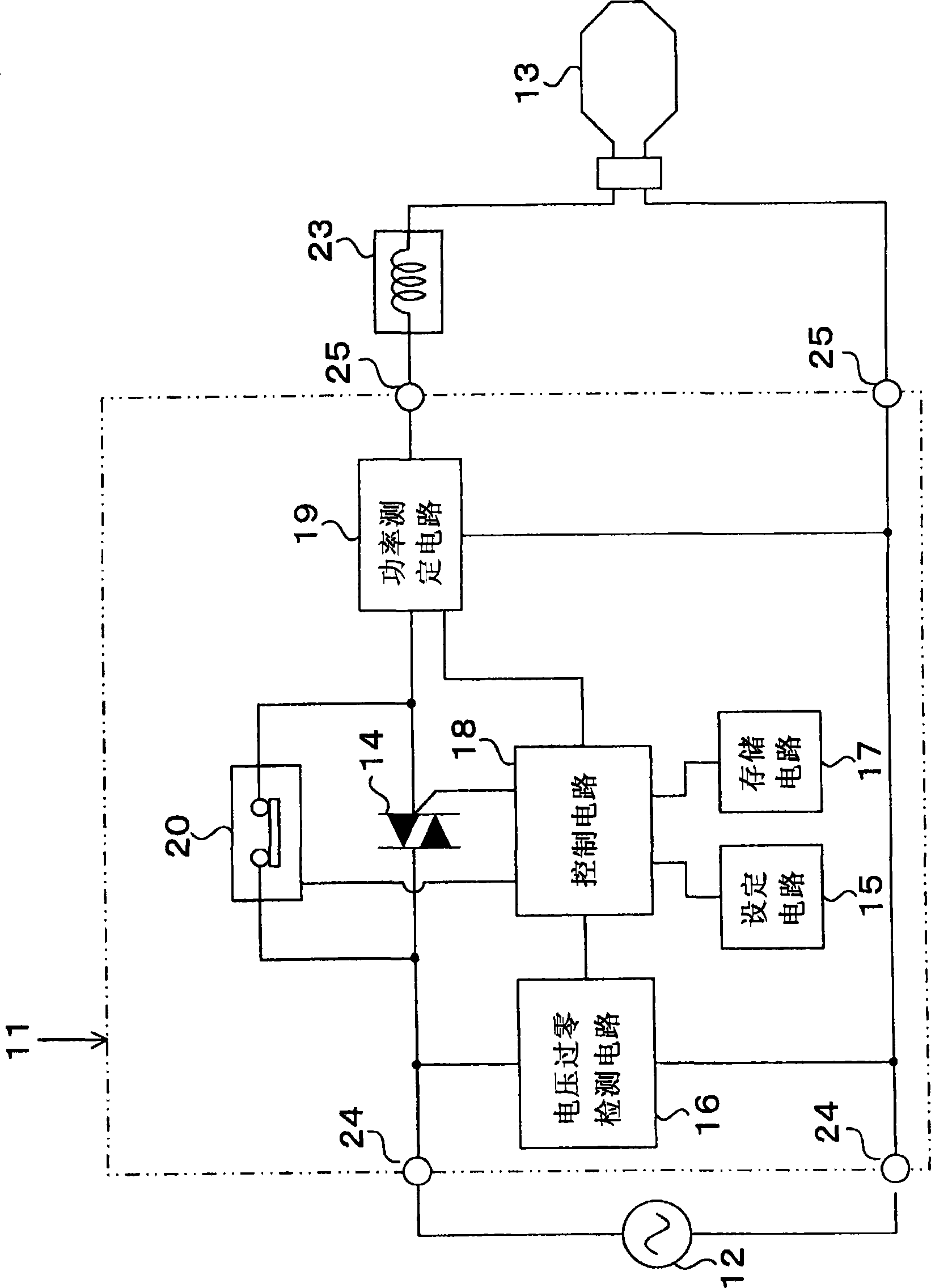

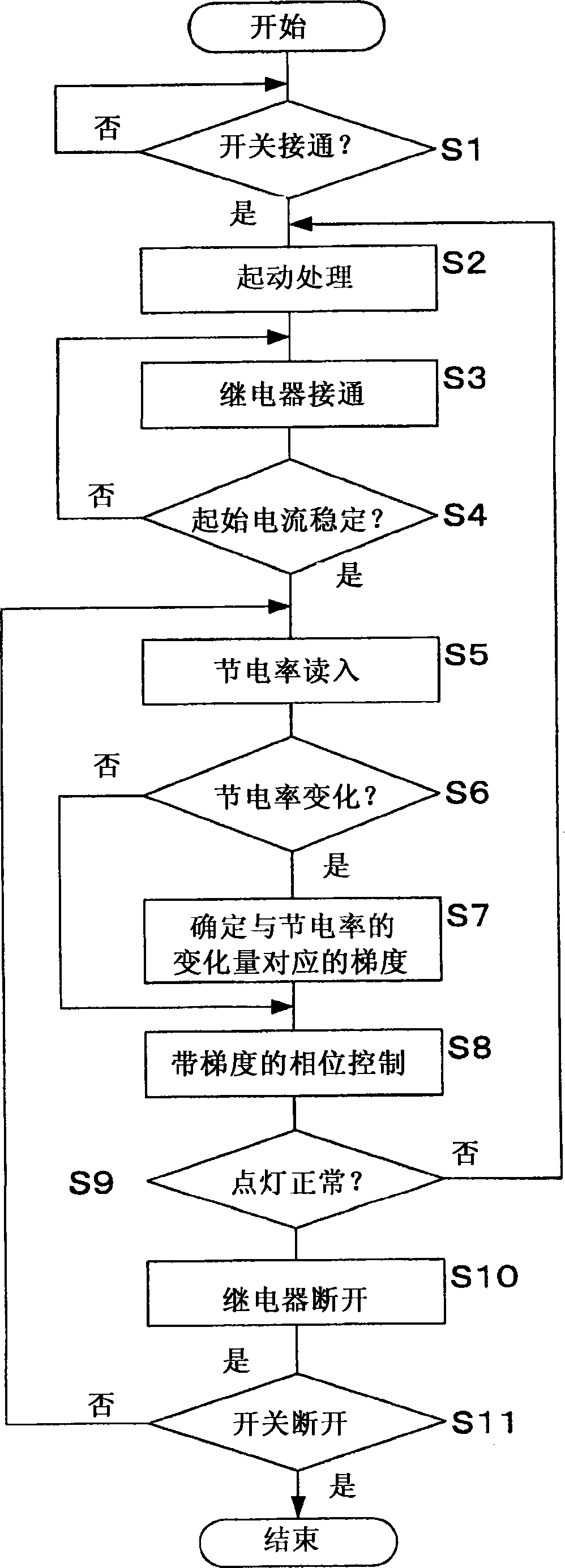

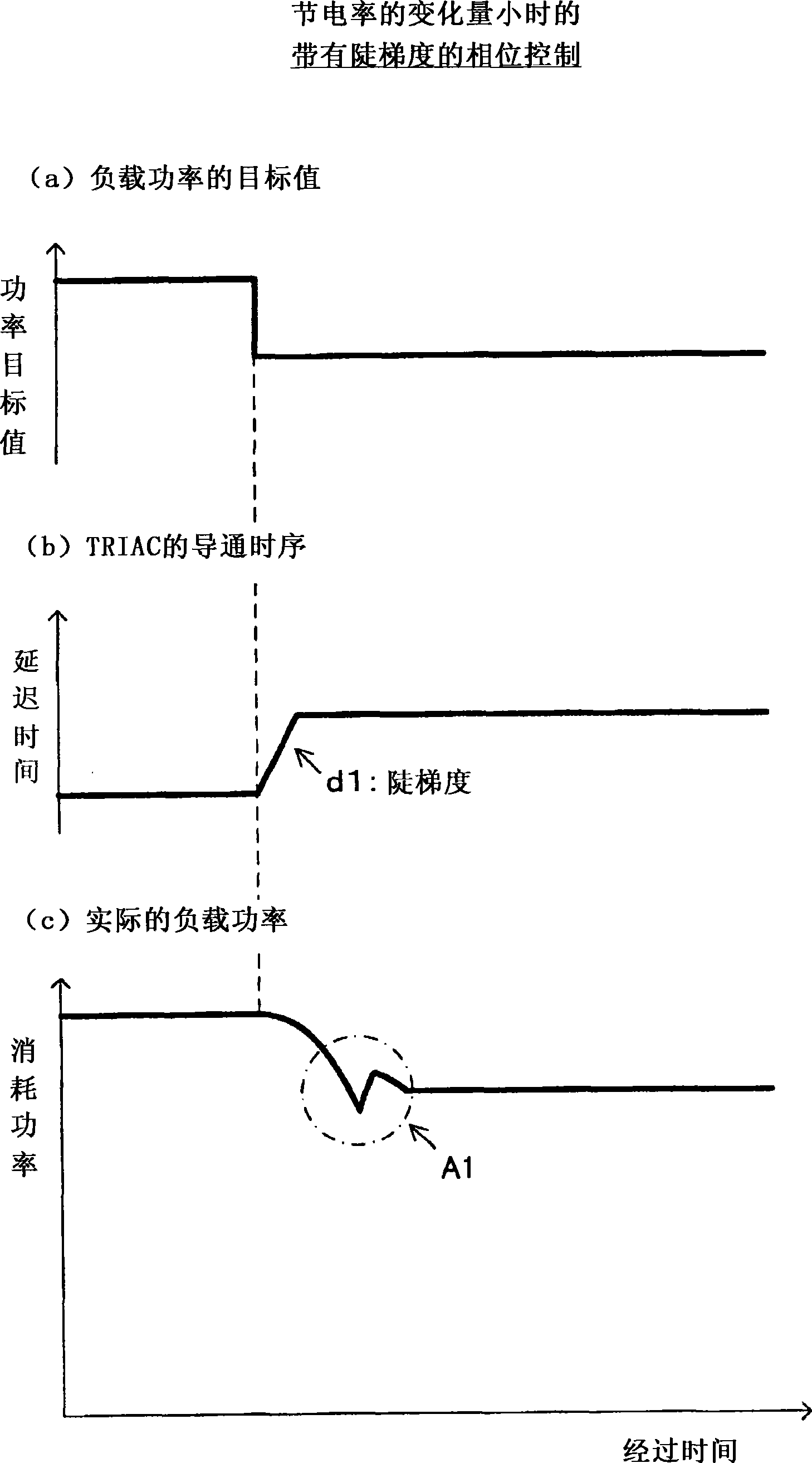

[0020] Embodiments of the present invention will be described below with reference to the drawings. Such as figure 1 As shown, the power saving device 11 of this embodiment includes: a TRIAC 14 as a power adjustment element, which adjusts the power supplied from the AC power supply 12 to the high-pressure discharge lamp 13; a control circuit 18, which controls the conduction sequence of the TRIAC 14; The setting circuit 15 of the disk is used to set the power-saving rate of the high-pressure discharge lamp 13; the voltage zero-crossing detection circuit 16 is used to detect the zero-crossing of the voltage waveform; delay time until turning on; and a power measurement circuit 19 for measuring the power consumption of the high pressure discharge lamp 13 .

[0021] Between the AC power source 12 and the high-pressure discharge lamp 13 , a relay 20 is provided in parallel with the TRIAC 14 . The control circuit 18 turns on the relay 20 just after the high-pressure discharge la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com