Low-voltage motor protection method and device thereof

A motor and low-voltage technology, applied in the direction of emergency protection circuit devices, electrical components, etc., can solve the problems of contactor burnout, expansion, and low-voltage motors not being protected, so as to achieve safe and reliable cut-off, good application prospects, increased safety and The effect of operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

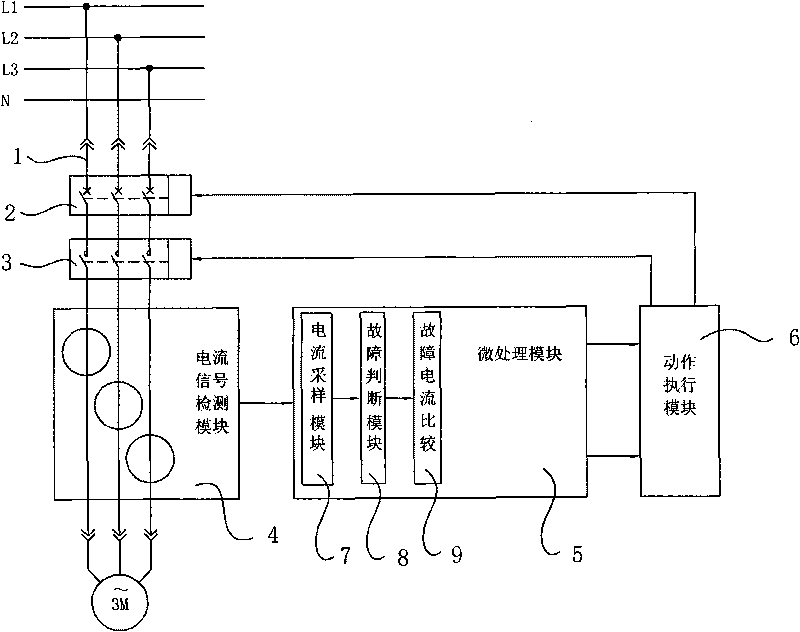

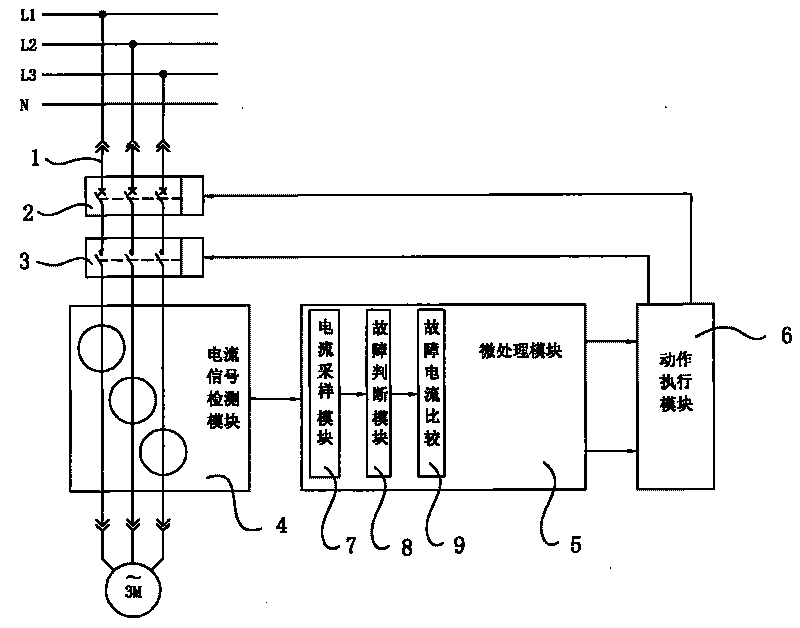

[0019] combine figure 1 The special feature of the low-voltage motor protection method shown is that first, the current in the low-voltage motor circuit 1 is detected by the current signal detection module 4, and then the current signal detection module 4 transmits the detection result to the micro-processing module 5, and the micro-processing The module 5 performs analysis and calculation and sends an action command to the execution module to control the disconnection of the contactor 3 or the circuit breaker.

[0020] Further, if the micro-processing module 5 finds that there is a fault current in the circuit, and the fault current is less than the allowable breaking current of the contactor 3, the microprocessor sends a normal fault action command to the execution module, and the execution module receives the command. Open the contactor 3, thereby disconnecting the low-voltage motor circuit 1. Specifically, at this time, the fault current in the circuit is small, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com