Control system

A flow control and capacity control technology, applied in the field of control systems, which can solve the problems of prolonged pull-down time, reduced pull-down speed, and insufficient cooling liquid system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

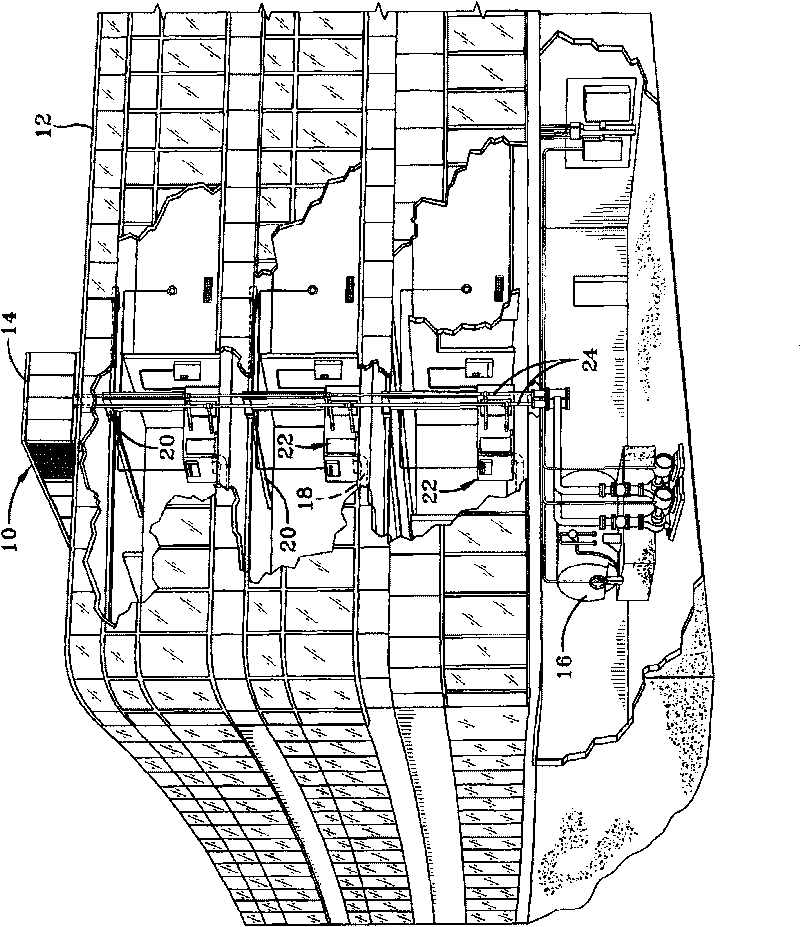

[0013] figure 1 An exemplary environment is shown for the refrigeration liquid system 10 in a building 12 for a typical commercial setting. System 10 may include a vapor compression system incorporated into rooftop unit 14 that may supply a refrigerated liquid that may be used to cool building 12 . System 10 may also include a boiler 16 that supplies heated liquid that may be used to heat building 12 , and an air distribution system that circulates air within building 12 . The air distribution system may include an air return duct 18 , an air supply duct 20 and an air handler 22 . Air manager 22 may include a heat exchanger connected to boiler 16 and rooftop unit 14 by conduit 24 . Depending on the mode of operation of system 10 , the heat exchanger in air manager 22 may receive heated liquid from boiler 16 or cooled liquid from rooftop unit 14 . System 10 is shown with separate air managers on each floor of building 12, but it should be appreciated that these components ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com