Liquid crystal display device

A liquid crystal display device and liquid crystal layer technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of liquid crystal molecular orientation disorder, reduced manufacturing efficiency, and reduced contrast, and achieve fast response speed, improved manufacturing efficiency, and high brightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Hereinafter, embodiments of the liquid crystal display device of the present invention will be described with reference to the drawings.

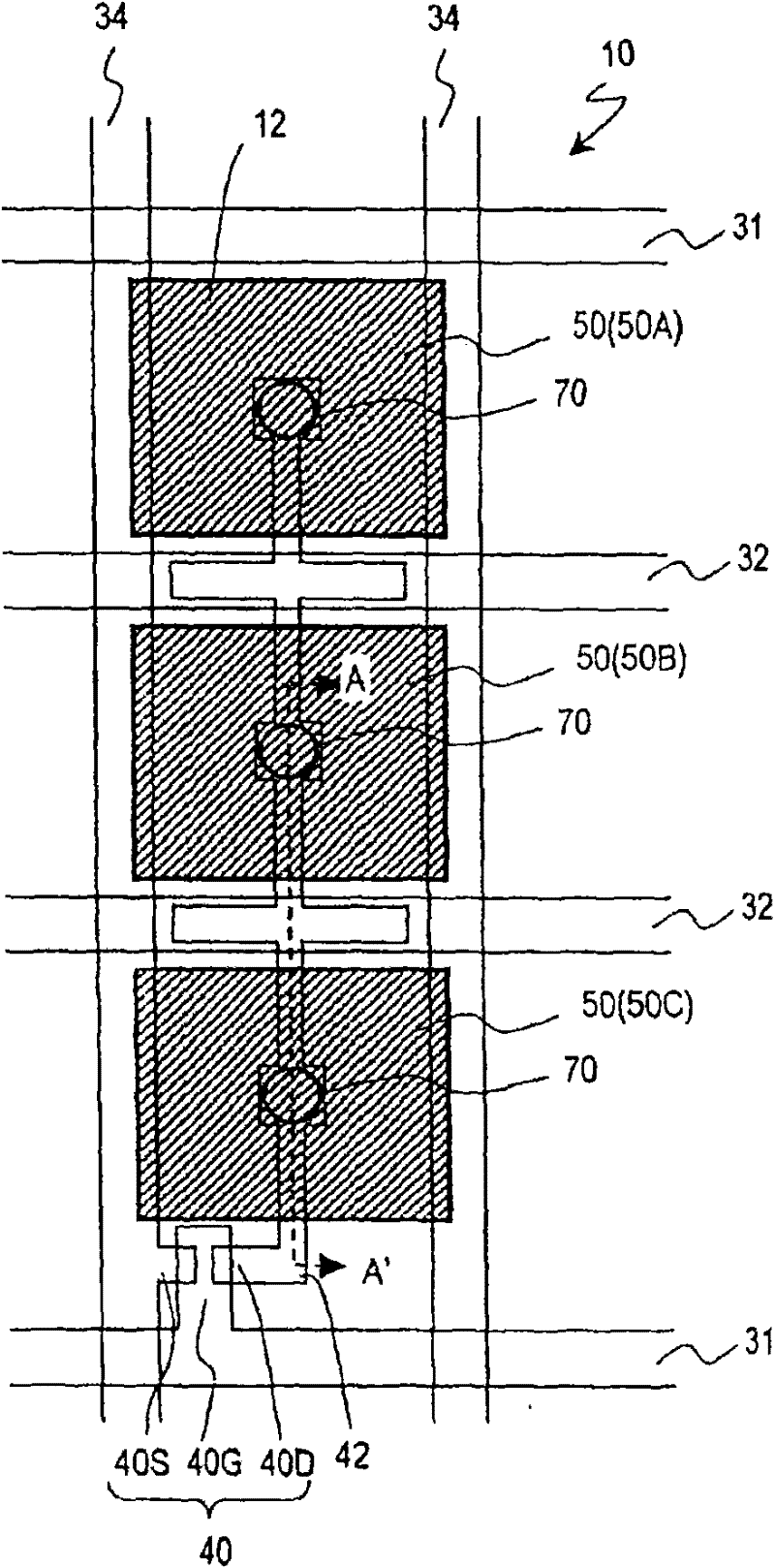

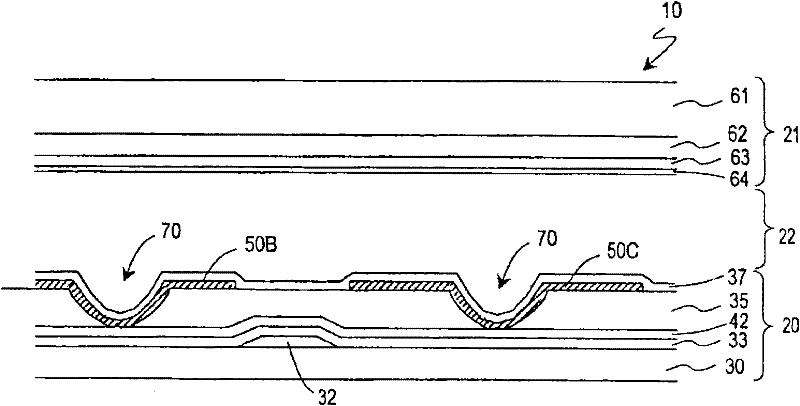

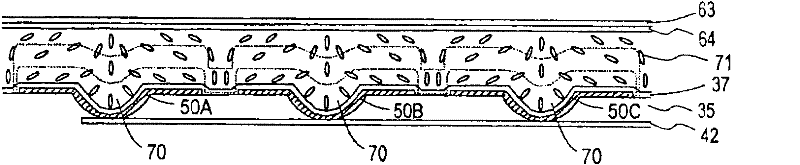

[0080] figure 1 is a plan view schematically showing the structure of one of the plurality of pixels 12 arranged in a matrix in the liquid crystal display device 10 of the present embodiment, figure 2 is a schematic representation of the liquid crystal display device 10 figure 1 A diagram of the shape of the A-A' cross-section.

[0081] In addition, in this specification, the minimum unit of display and the part corresponding to it are referred to as a pixel. For example, in a liquid crystal display device that performs color display using three colors R (red), G (green), and B (blue) , a pixel unit is composed of three pixels of R, G, and B. A pixel is defined as an area surrounded by two adjacent gate bus lines (scanning lines) and two adjacent source bus lines (signal lines) extending perpendicularly to the extending directi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com