Scraper device and method for removing residue attached to bottle shaped objects

A scraper device and technology for residues are applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., and can solve the problems of difficult liquid crystal extraction and high price of liquid crystal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

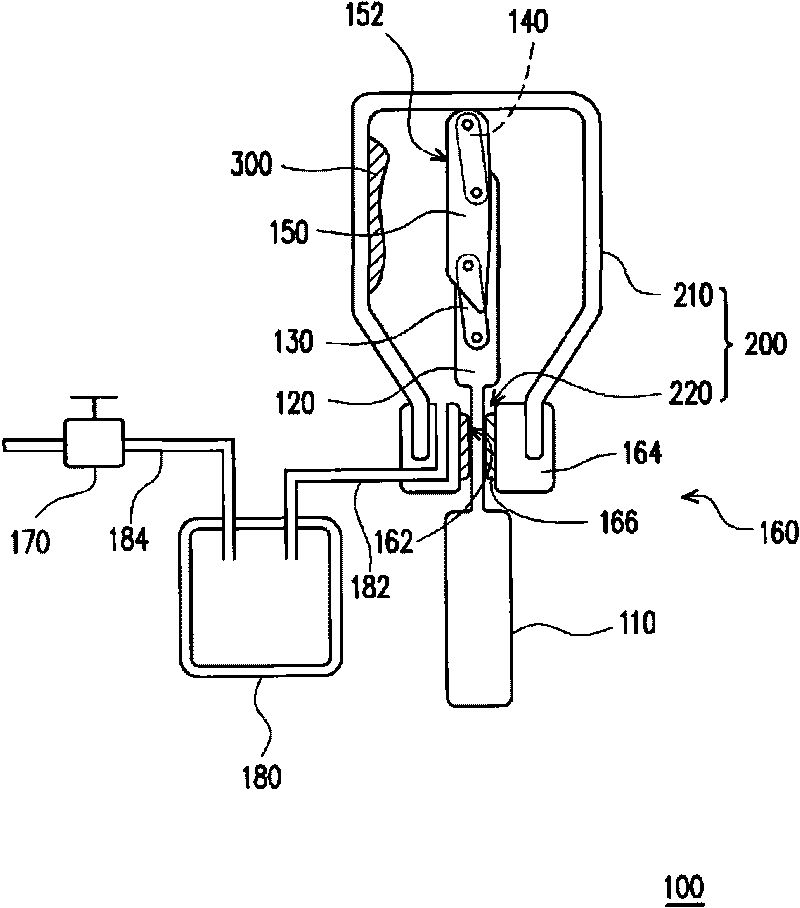

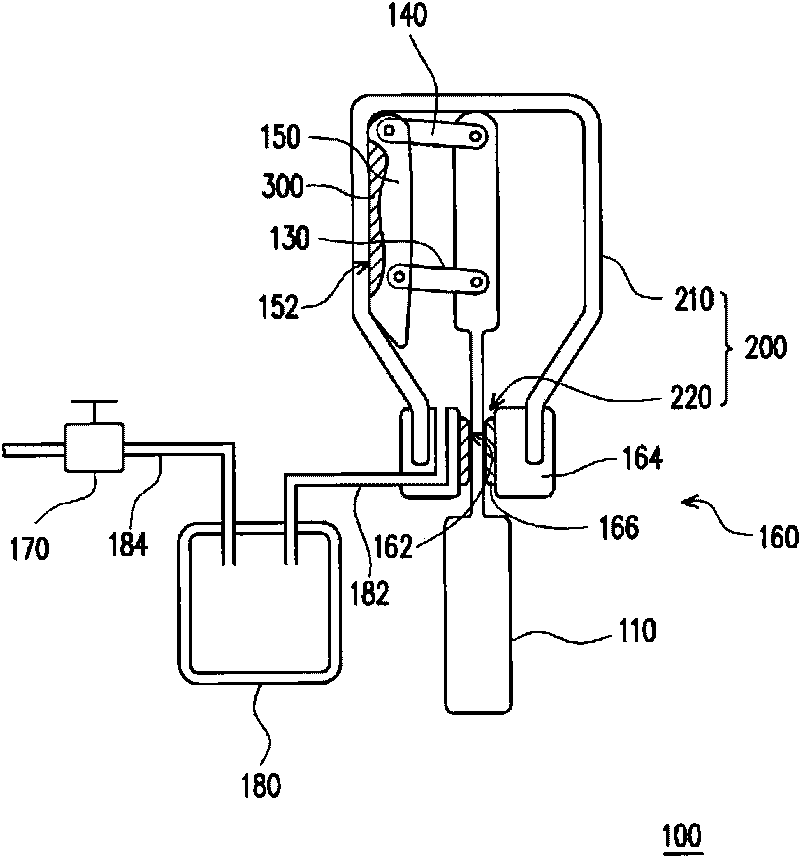

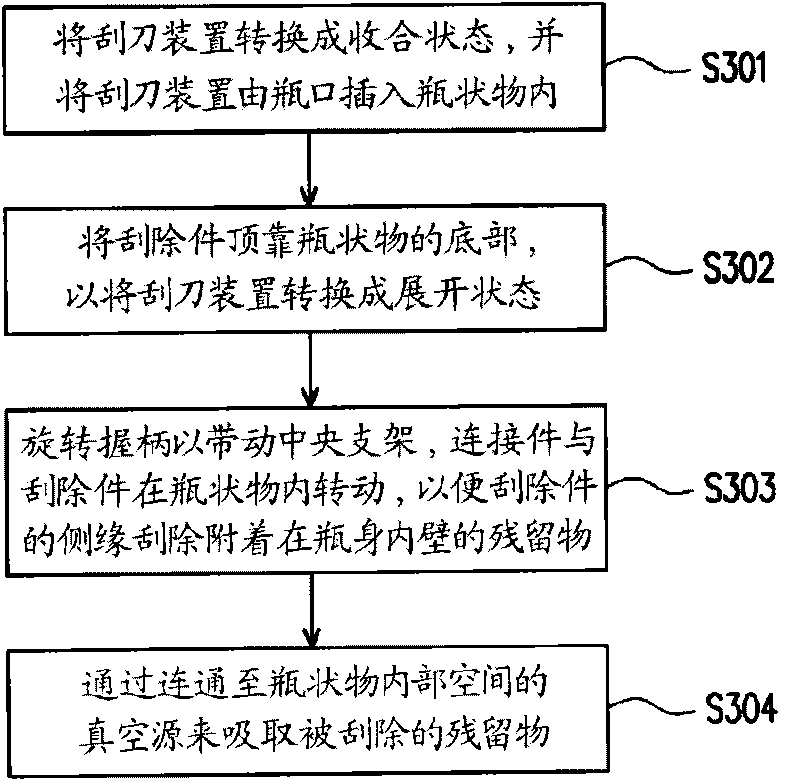

[0040] figure 1 It is a cross-sectional view of a scraper device in a bottle in a folded state according to an embodiment of the present invention. figure 2 yes figure 1 The sectional view of the scraper device in the unfolded state, in which the residue in the bottle is indicated by oblique lines. Please also refer to figure 1 and figure 2 , in this embodiment, the bottle 200 is used to contain liquid crystal. After the liquid crystal is used up, there will still be a little liquid crystal residue 300 remaining on the inner wall of the bottle body 210 in the empty bottle. In this embodiment, the bottle 200 is not limited to contain liquid crystals, and other high-viscosity liquid materials are also suitable for this embodiment.

[0041] The scraper device 100 is used to remove the residue 300 attached to the inner wall of the bottle body 210 of the bottle 200 . The bottle 200 has a bottle mouth 220 , and the diameter of the bottle mouth 220 is smaller than the inner d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com