Semi-automatic envelope machine

A semi-automatic, sealing technology, applied in book binding, binding adhesives, printing, etc., can solve problems such as difficult to take out, uneven, uneven envelopes, etc., to reduce the contact area, easy to scrape off hot melt glue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

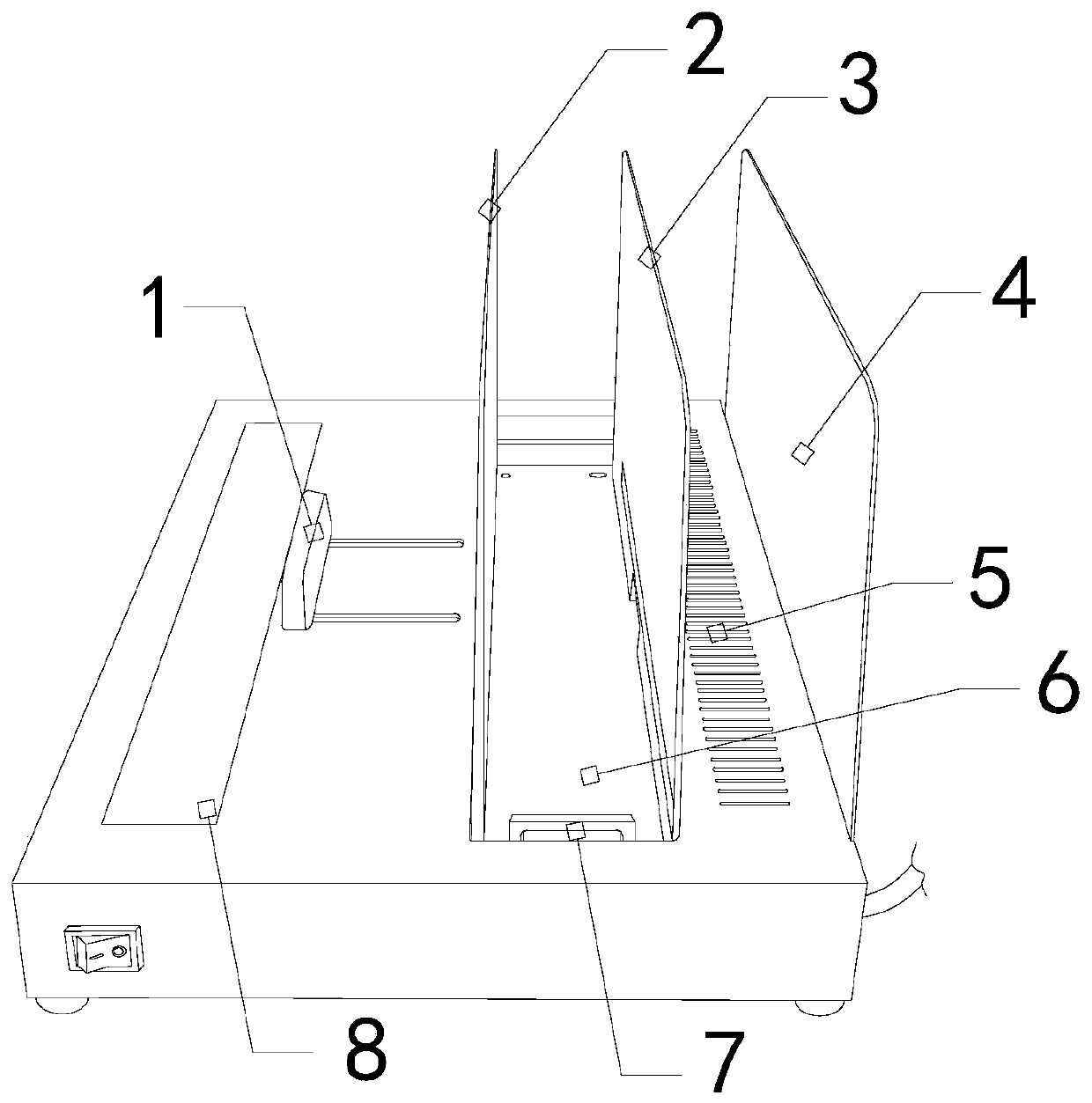

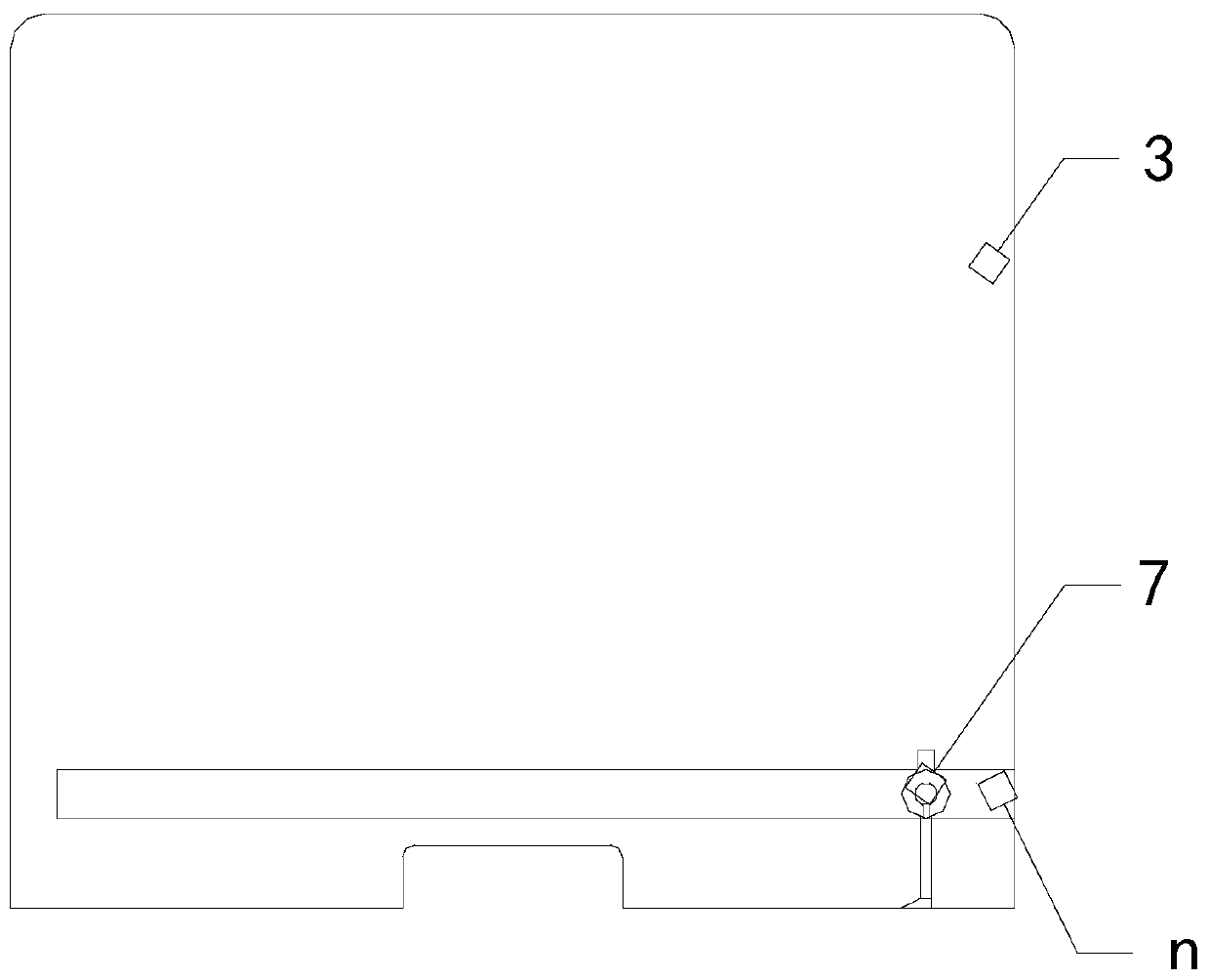

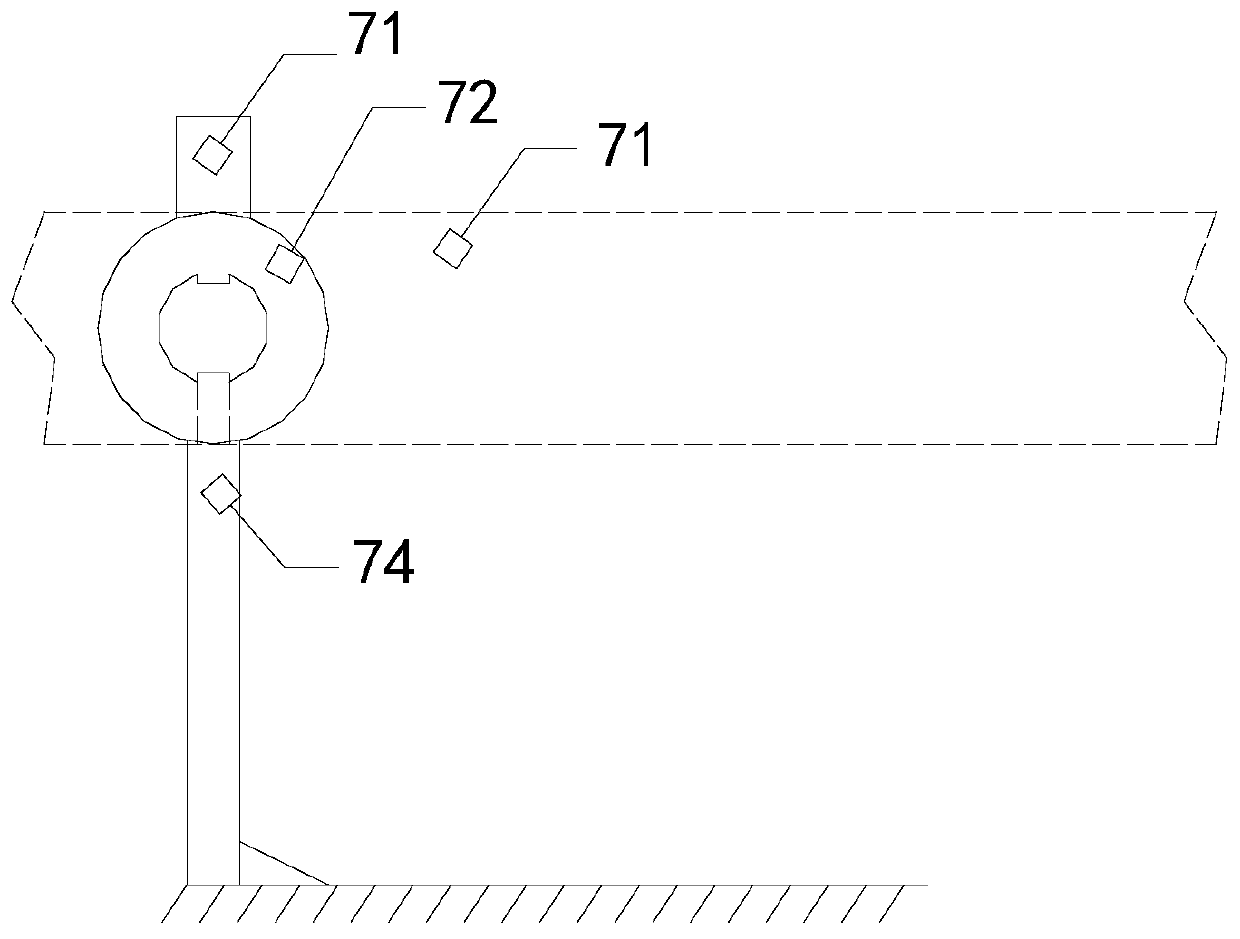

[0025] see Figure 1-Figure 5 , the present invention provides a semi-automatic enveloping machine, the structure of which includes a clamping switch 1, a first clamping plate 2, a second clamping plate 3, a partition plate 4, a heat dissipation port 5, a hot melt tank 6, and a glue removal structure 7. The body 8, the heat-melting tank 6 is opened at one end of the body 8, one side of the heat-melting tank 6 is provided with a cooling port 5, and the other side opposite to the cooling port 5 is provided with a clamping switch 1, the The interior of the hot-melt tank 6 is provided with a first clamping plate 2 and a second clamping plate 3 parallel to each other, and the second clamping plate 3 is vertically fixed on the bottom surface of the heat dissipation port 5 close to the hot-melt tank 6 , and the first The clamping plate 2 and the clamping switch 1 are fixed horizontally, the partition plate 4 is vertically fixed on the body 8, and the center line of the partition plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com