Electric hand drill

A hand electric drill and handle technology, used in portable drilling rigs, drilling/drilling equipment, metal processing equipment, etc., can solve problems such as inconvenient operation, change of working gear, spin generation, etc., to enhance convenience and stability. , to avoid the effect of changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

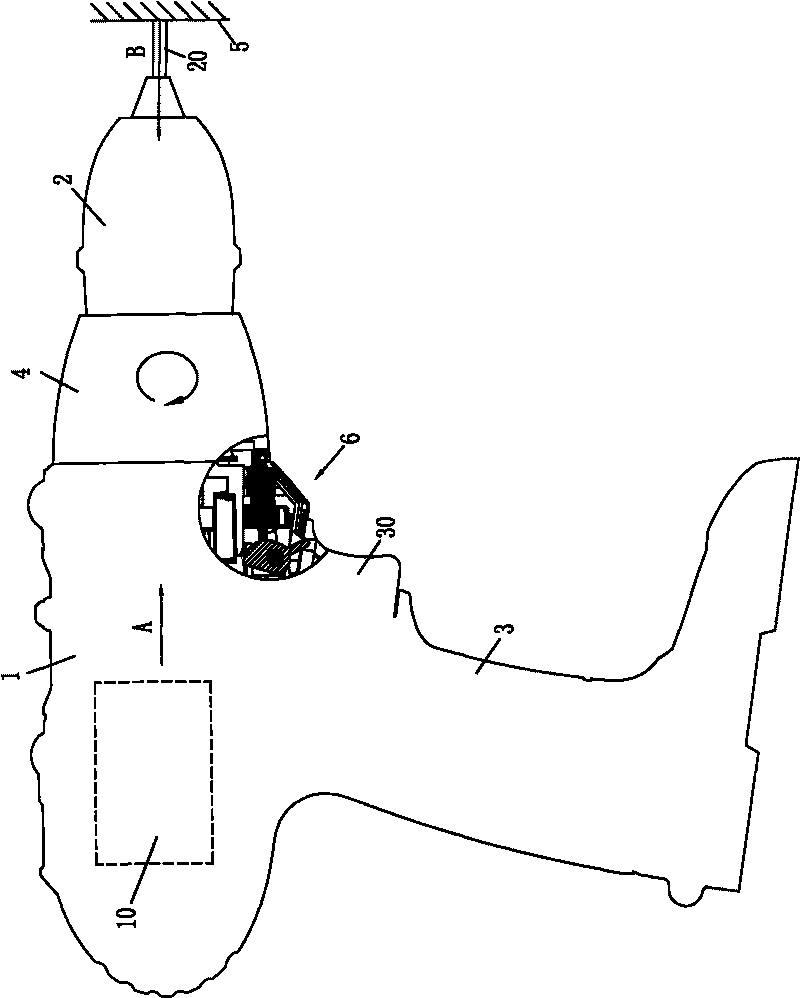

[0016] see figure 1 , a hand electric drill, including a housing 1, a drill chuck 2 and a handle 3. A motor 10 is arranged inside the housing 1 , and the motor 10 is controlled by a switch 30 on the handle 3 to be in an on or off state. When the motor 10 is in the on state, that is, the switch 30 is pressed by the operator, the output of the motor 10 is along figure 1 The torque transmitted in direction A is transferred to the drill chuck 2. Various drill bits 20 can be installed on the drill chuck 2 as required, and the drill chuck 2 drives the drill bit 20 to rotate after receiving the torque transmitted by the motor 10 .

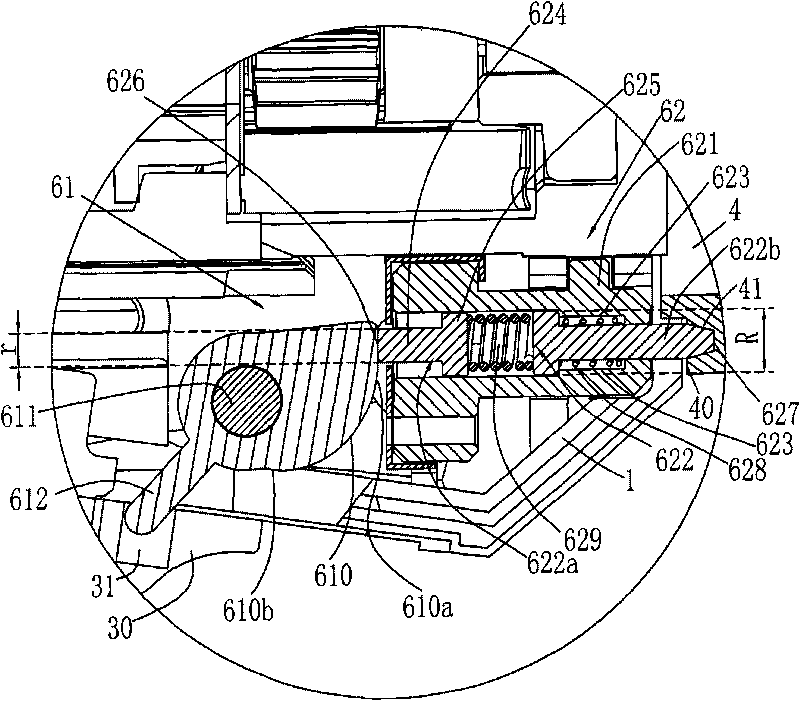

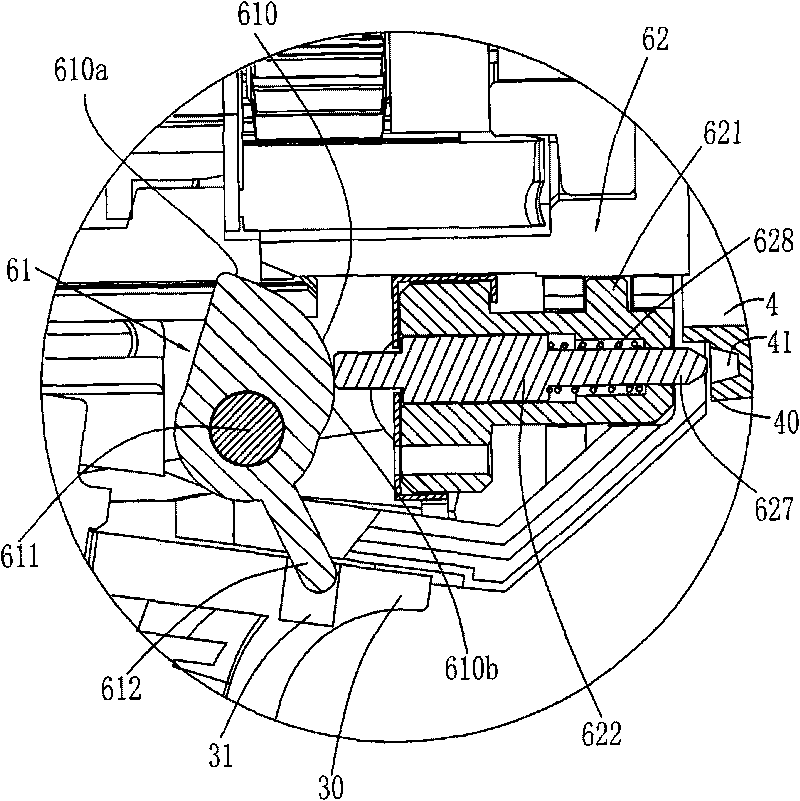

[0017] The electric hand drill also includes a torque cover 4 for adjusting the working gear of the drill chuck 2 , and the torque cover 4 is located between the casing 1 and the drill chuck 2 . During work, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com