On-line material logistic warehouse

A material and logistics technology, applied in the field of material online logistics warehouse and logistics warehouse, can solve the problems of low work efficiency, high labor intensity, and chaotic placement, so as to improve work efficiency, reduce labor intensity, and arrange neatly and orderly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with reference to the accompanying drawings.

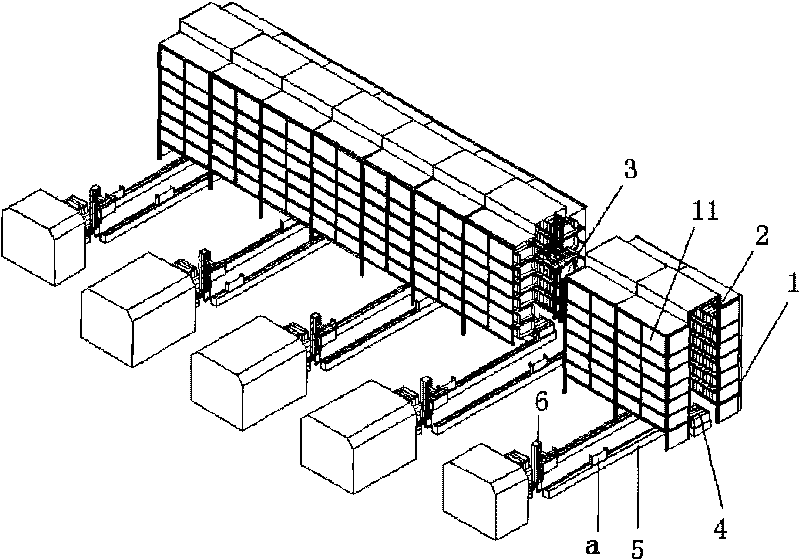

[0038] The material online logistics warehouse provided by the present invention includes a warehouse 1, a shelf 2 arranged in the warehouse 1, a horizontal rail is arranged on the shelf 2, and the horizontal rail is connected with a mobile access device 3 driven by a power machine through a slider on the horizontal rail, There is a material transfer device 4 connected to the external conveyor 5 at the entrance and exit of the cargo warehouse, and the other end of the external conveyor 5 is provided with a coordinate grabbing device 6; the external wall of the cargo warehouse 1 is set as a transparent plexiglass wall body 11, such as figure 1 ,in:

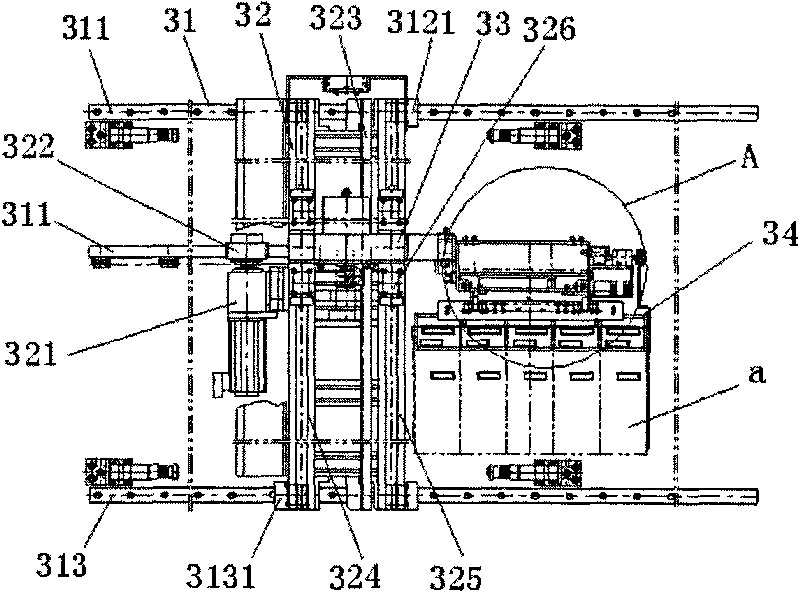

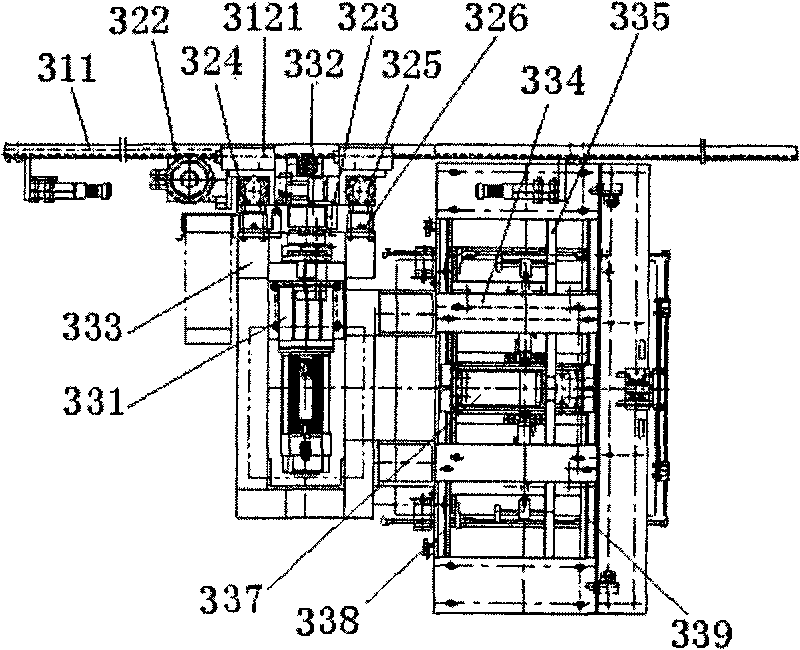

[0039] The mobile access device 3 includes a power machine-driven vertical rail 32 that reciprocates along the horizontal rail, which is connected with the moving slider on the horizontal rail 31, and a power machine-driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com