Flat knitting machine

A technology of flat knitting machine and machine head, which is applied in the direction of flat knitting machine with separate action needle, textile and paper making, weft knitting, etc. problem, to reduce friction and reduce pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

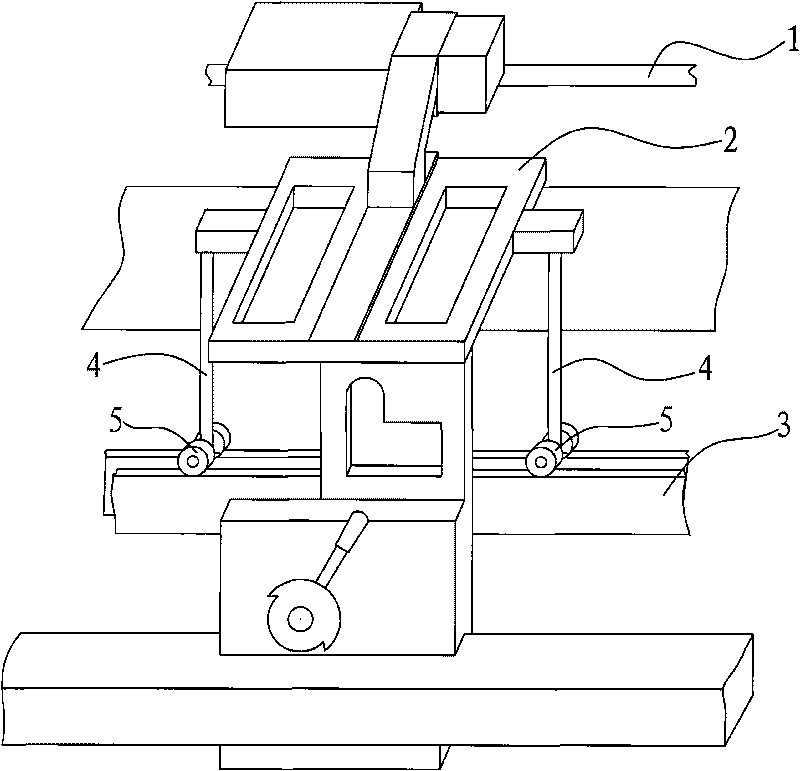

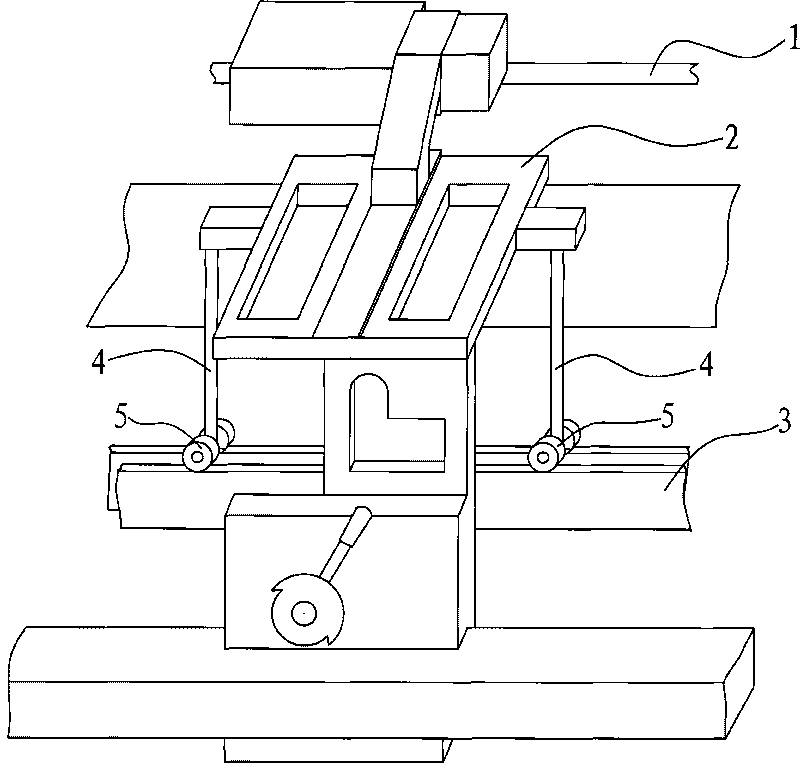

[0008] The specific embodiment of the present invention is described below: a kind of flat knitting machine, comprises guide rail 1, the machine head 2 that is slidably arranged on described guide rail 1, also comprises slide rail 3, symmetrically fixed on the two sides of described machine head 2 The two supports 4 are rotated and arranged on the rollers 5 at the bottom of each of the supports 4, and the rollers 5 are rollingly supported on the slide rails 3. The roller 5 supports the weight of the nose 2, reduces the pressure between the nose 2 and the guide rail 1, and then reduces the friction between the nose 2 and the guide rail 1; There is rolling friction between the rails 3, and the frictional resistance is very small, so the frictional force of the whole flat knitting machine can be greatly reduced, no matter for the automatic flat knitting machine or the manual flat knitting machine, the operation is labor-saving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com