Electric throttling distribution mechanism, air conditioner system and flow control method thereof

A distribution mechanism and electric throttling technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of large number of components, complicated pipeline connections, high manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

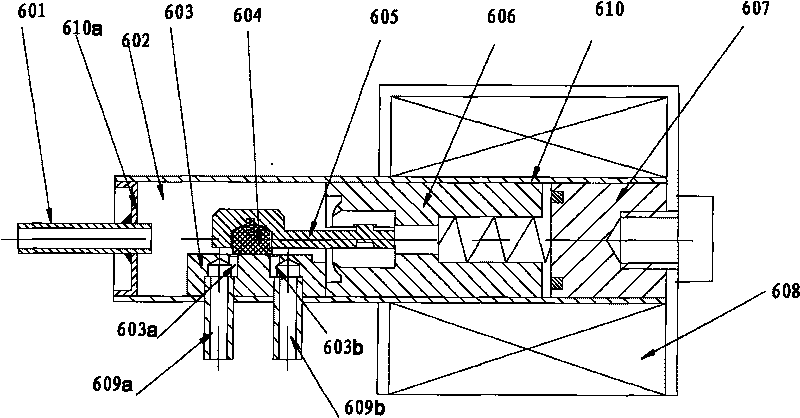

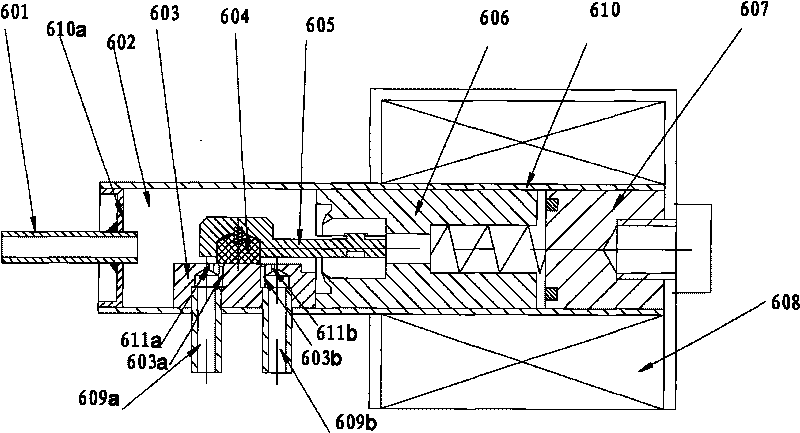

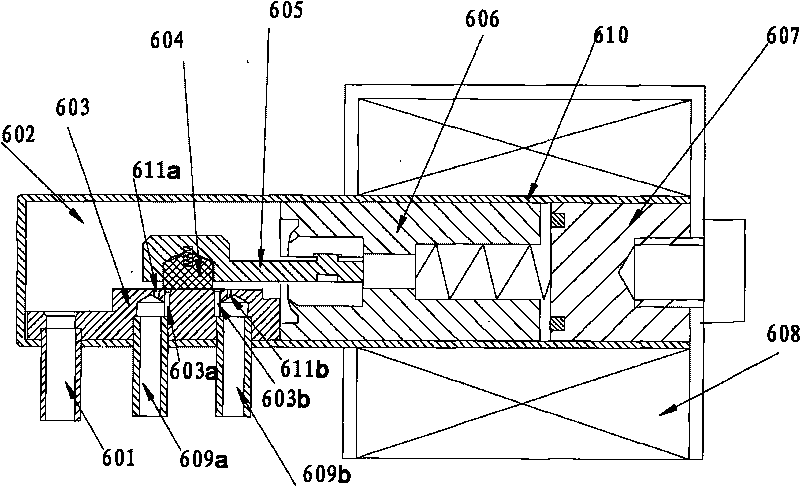

[0029] figure 2It is the second embodiment of the electric throttling distribution mechanism of the present invention. The difference between this embodiment and the first embodiment is that, on the valve seat 603, there are also valves respectively communicating with the outlet connecting pipes 609a, 609b and at the same time communicating with all outlet pipes. The valve cavity 602 maintains communication with the normally open orifice 611a, 611b, the normally open orifice 611a and the orifice 603a are connected with the outlet connecting pipe 609a at the same time, and the normally open orifice 611b and the orifice 603b are simultaneously connected with the outlet The connecting pipe 609b is connected, so that the flow rate of the outlet connecting pipe is the throttled flow of a normally open orifice plus the flow after being throttled and distributed by an orifice, so that when the required flow rate of the outlet connecting pipe remains unchanged , the flow rate to be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com