Oil-retaining structure inside bearing pad machine for large-scale turbogenerator rotor dynamic balance test

A dynamic balancing technology for turbogenerators and rotors, which is applied in static/dynamic balance testing, engine testing, machine/structural components testing, etc., and can solve problems such as oil leakage and lack of oil retaining structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

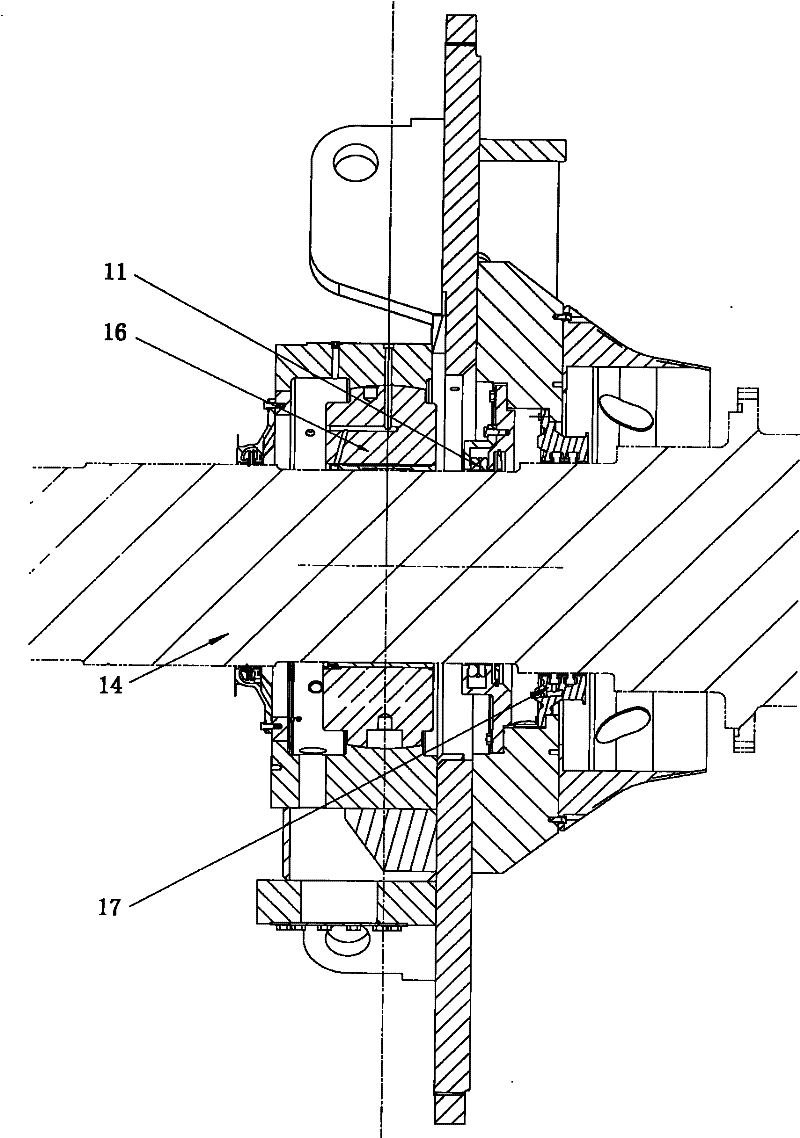

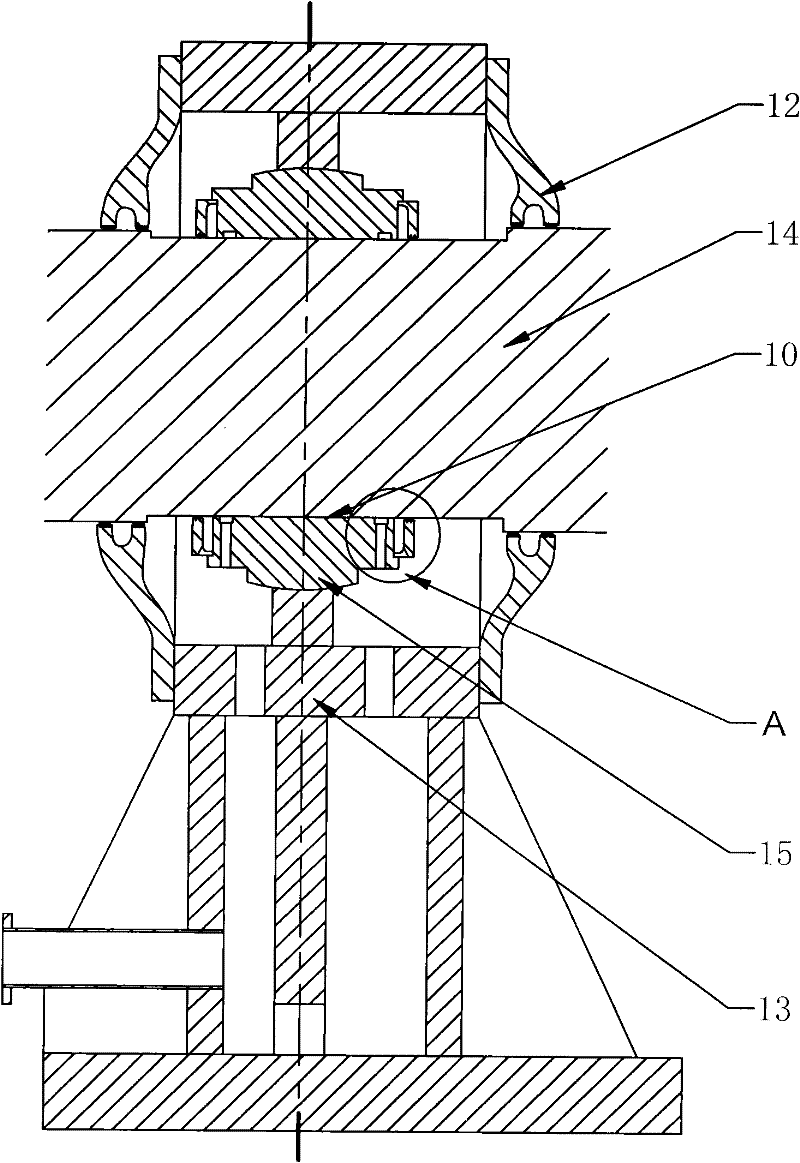

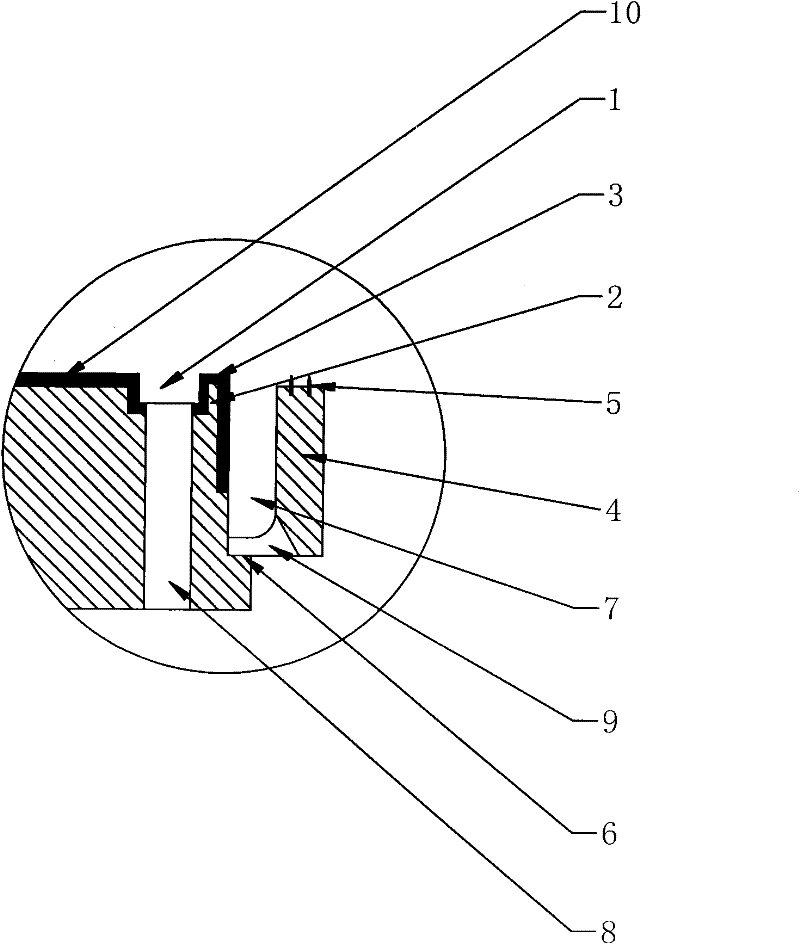

[0020] like image 3 The present invention shown is a large turbogenerator rotor dynamic balance test bearing pad machine inner oil retaining structure, the test bearing pad 15 is installed on the inner side of the machine adjacent to the test bearing pad bearing surface 10, and the outer end of the test bearing pad bearing surface 10 is an oil drain groove 1. There is a first oil discharge hole 8 at the bottom of the oil drain tank 1, and the test bearing body outside the oil drain tank 1 forms an oil retaining platform 2, and the surface of the oil retaining platform 2 has a tungsten gold structure layer 3, and a small stopper is assembled on the end surface of the test bearing shell 15 The oil cover 4, the copper comb teeth 5 inlaid with the small oil retainer 4, the upper stop 6 between the small oil retainer 4 and the test bearing bush 15, the first oil discharge hole 8 at the bottom of the oil drain groove 1, the small oil retainer An oil drain chamber 7 is formed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com