Manufacturing method for absorbent products and manufacturing device for absorbent products

A manufacturing method and absorbent technology are applied in the field of manufacturing of absorbent articles and manufacturing devices of absorbent articles, which can solve problems such as material waste, and achieve the effect of preventing inconsistency between left and right positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

change example 1

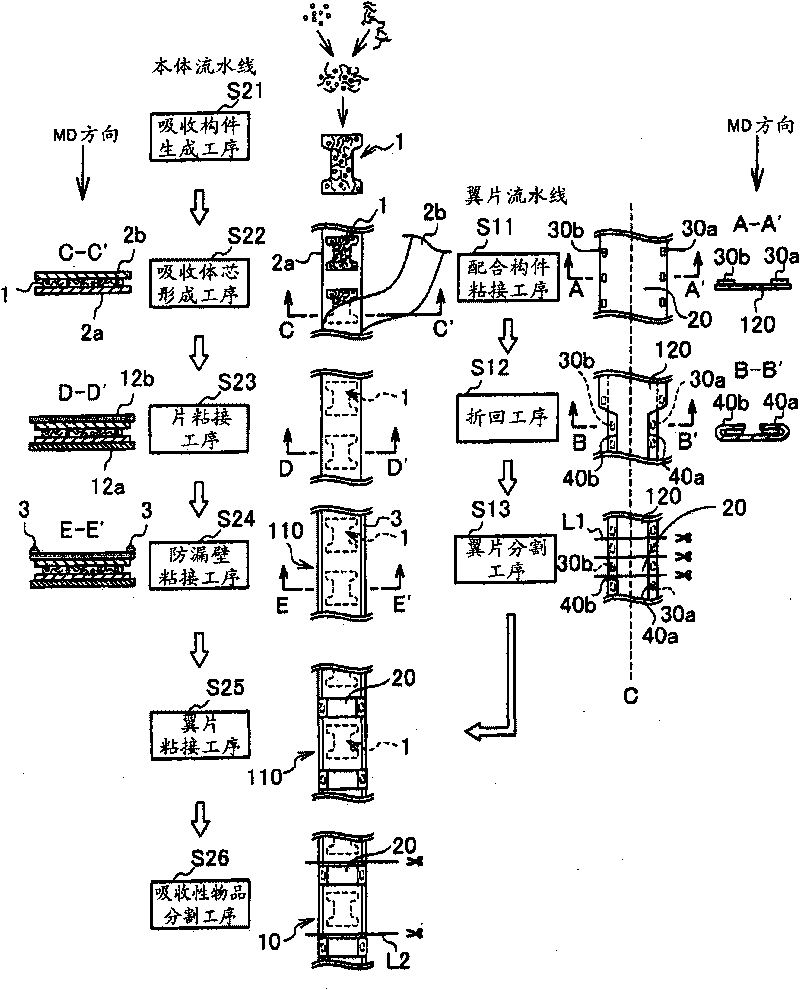

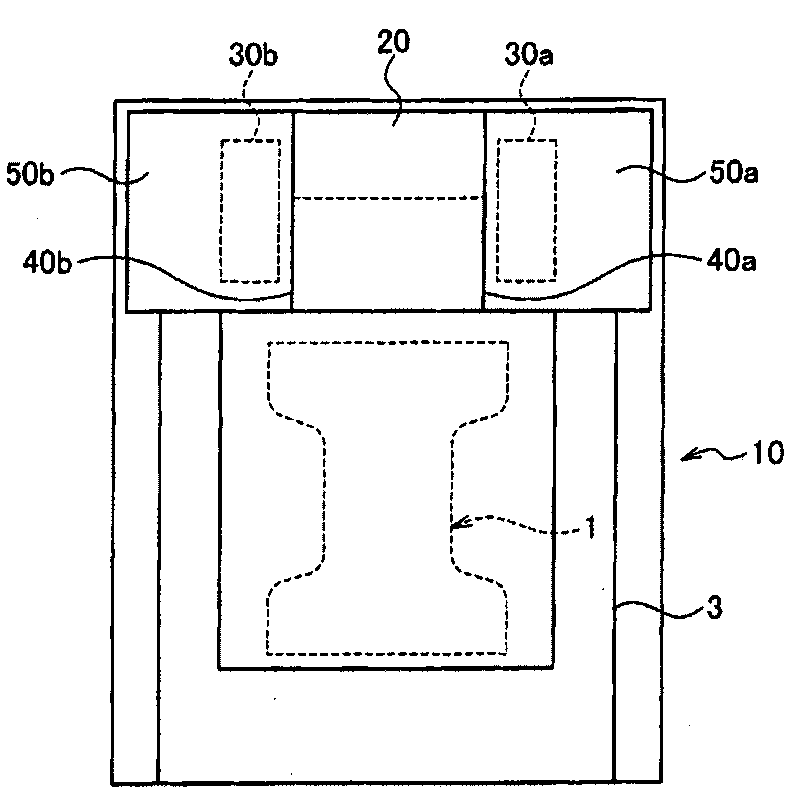

[0058] refer to Figure 4 to Figure 7 A method for manufacturing an absorbent article according to Modification 1 of the present invention will be described. Next, the manufacturing method of the absorbent article according to Modification 1 of the present invention will be described focusing on differences from the manufacturing method of the absorbent article according to the first embodiment of the present invention.

[0059] In the manufacturing method of the absorbent article according to this modified example 1, in step S12, the both side edge parts 41a, 41b of the continuous body 120 of a flap are folded back several times on a flap line.

[0060] For example, if Figure 4 As shown in (a), in step S12, on the airfoil assembly line, when the both side edges 41a, 41b of the continuum 120 of the airfoil are folded back twice, as Figure 5 As shown in (a), the engaging members 31a and 31b are in an upward state. Therefore, since the engaging members 31a, 31b cannot be lo...

change example 2

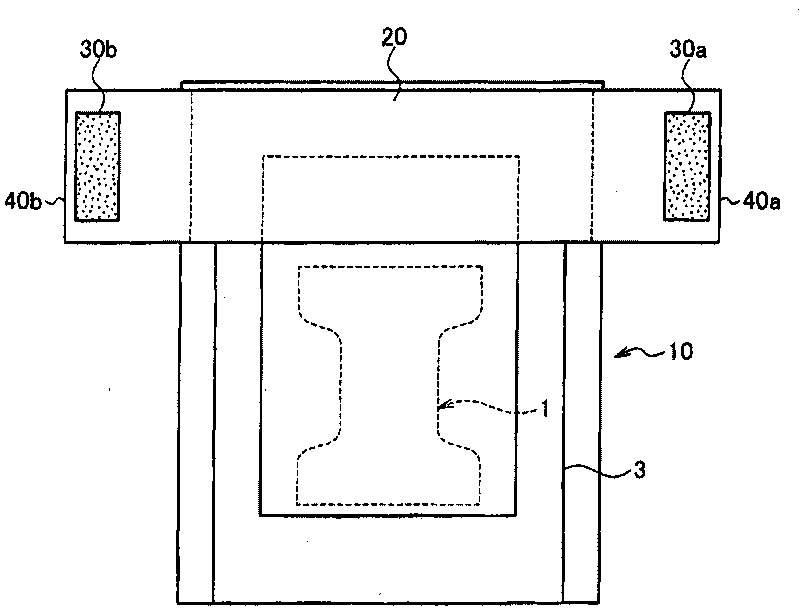

[0065] refer to Figure 8 A method for manufacturing an absorbent article according to Modification 2 of the present invention will be described. Next, the manufacturing method of the absorbent article according to Modification 2 of the present invention will be described focusing on differences from the manufacturing method of the absorbent article according to the first embodiment of the present invention.

[0066] First, the steps performed on the airfoil line will be described.

[0067] In step S11, in the continuous body 120 of elongated airfoils continuously conveyed on the airfoil line, on both sides of the center line C along the MD direction of the airfoil line, fittings that can fit into a predetermined area are arranged. Members 32a, 32b.

[0068] Specifically, in the fin continuum 120 , the engagement members 32 a , 32 b are arranged at predetermined length intervals on both sides of the vicinity of the centerline C along the MD direction of the fin line.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com