Egg hatching tray

A technology for hatching trays and eggs, which is applied in the field of poultry breeding, can solve the problems of poor ventilation, non-concentrated hatching time, small gaps, etc., and achieve the improvement of hatching rate and healthy chick rate, centralized hatching time, and increased ventilation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

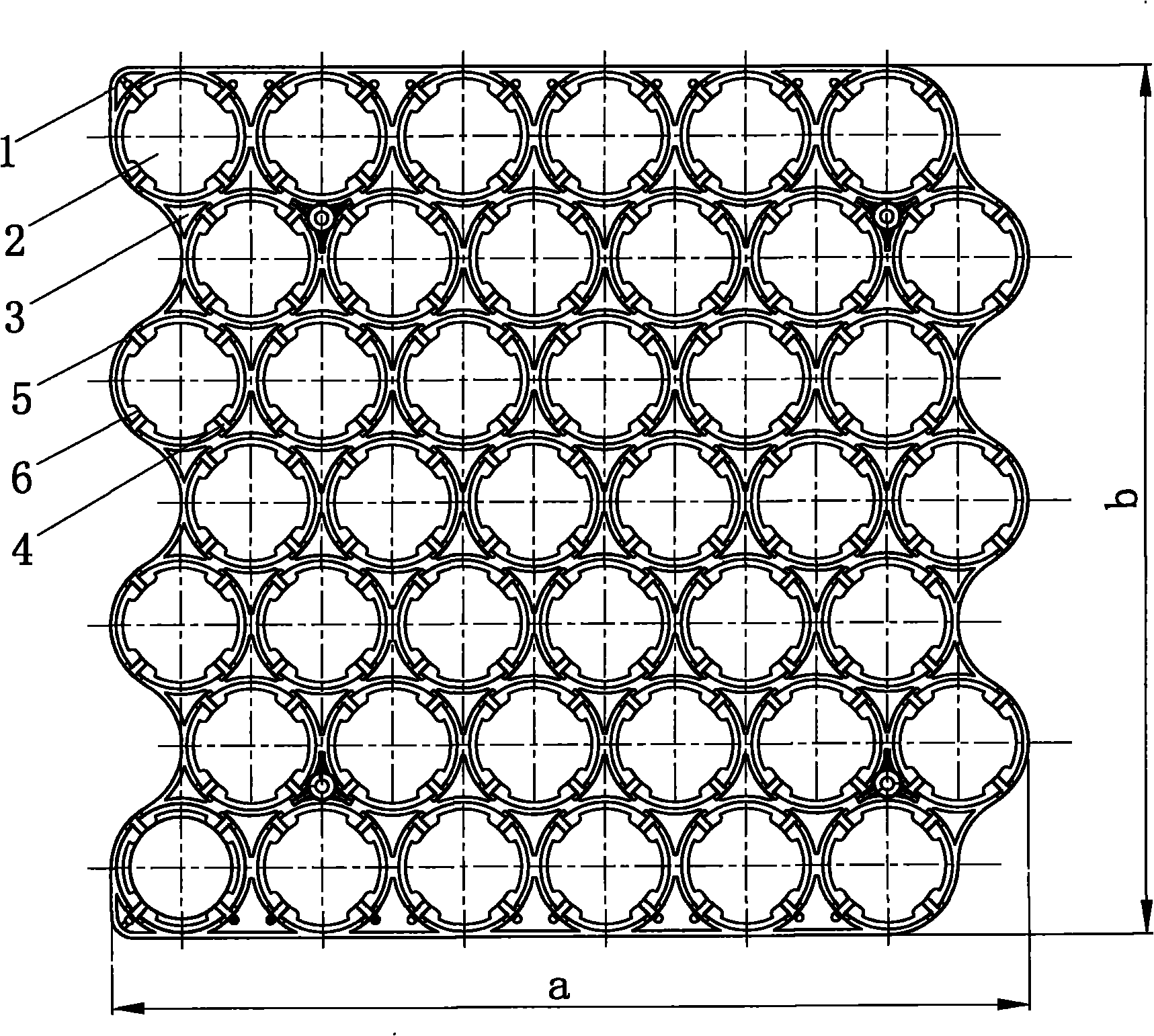

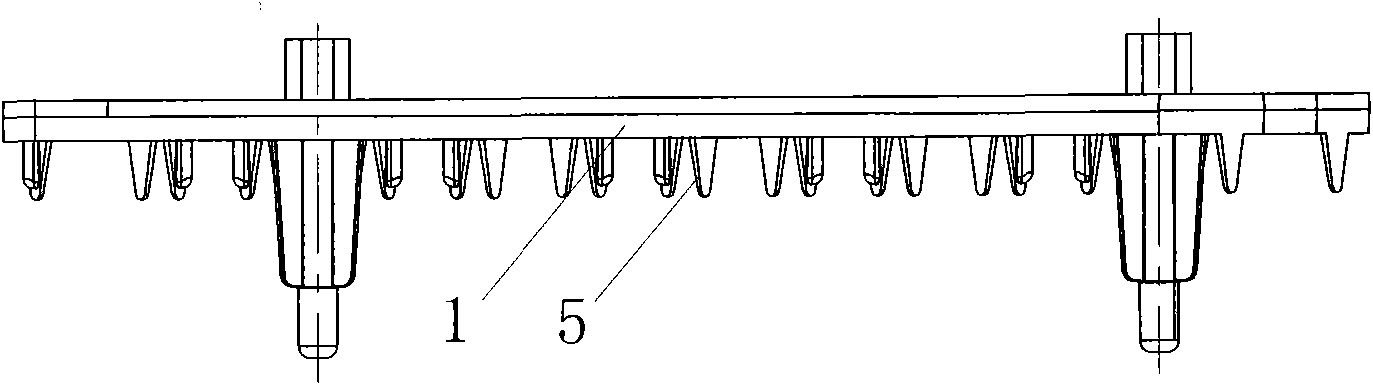

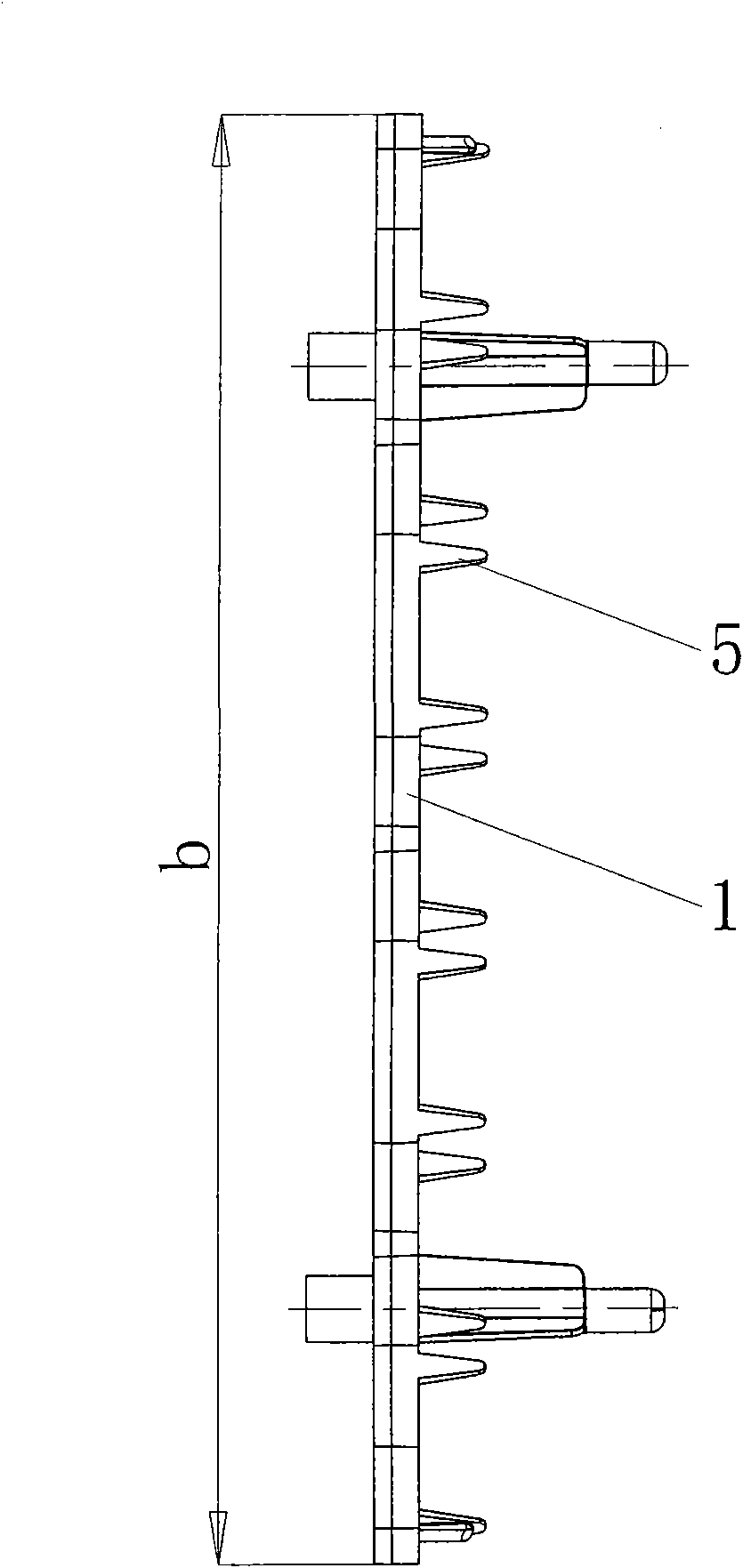

[0013] Embodiment 1: as Figure 1-Figure 3 As shown, the egg hatching tray of the present invention has a number of egg placement holes 2 on the tray 1, the egg placement holes 2 are arranged in a criss-cross pattern, and ventilation holes 3 are opened between two adjacent rows of egg placement holes 2.

[0014] In order to place the eggs stably and maintain good ventilation, four protrusions 6 are uniformly arranged along the circumference of the egg position hole 2 described in this example, and arc-shaped reinforcing ribs 4 are arranged between the protrusions 6 and the frame 5 . When the egg is placed in the egg position hole, it is in 4-point contact with the bump 6 and the reinforcing rib 4.

[0015] The length a of the hatching tray of this example is 343mm, the width b is 326mm, and 42 eggs can be placed. The incubation tray of this example is made of plastic.

Embodiment 2

[0016] Embodiment 2: as Figure 1-Figure 3 As shown, the structure of this example is the same as that of Example 1, except that the length a of the egg hatching tray of this example is 300mm, and the width b is 300mm. The incubation tray of this example is made of plastic.

Embodiment 3

[0017] Embodiment 3: as Figure 1-Figure 3 As shown, the structure of this example is the same as that of Example 1, and the difference is that the length a of the egg hatching tray of this example is 320mm, and the width b is 310mm. The incubation tray of this example is made of plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com