Raw coal centrifugal dewaterer for coal mines

A centrifugal and dehydrator technology, used in centrifuges, centrifuges with rotating drums, etc., can solve problems such as environmental pollution, reduce production efficiency, and long processing cycles, reduce production costs, improve production efficiency, The effect of reducing manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

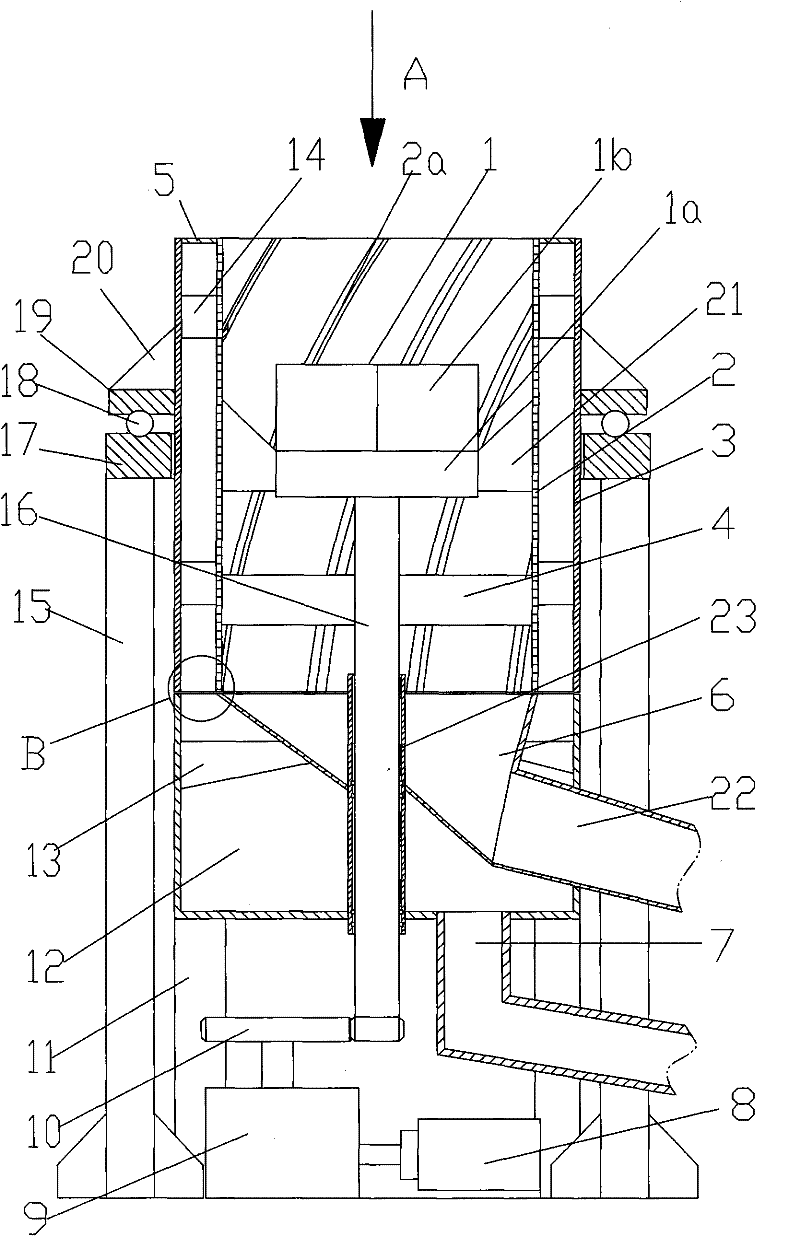

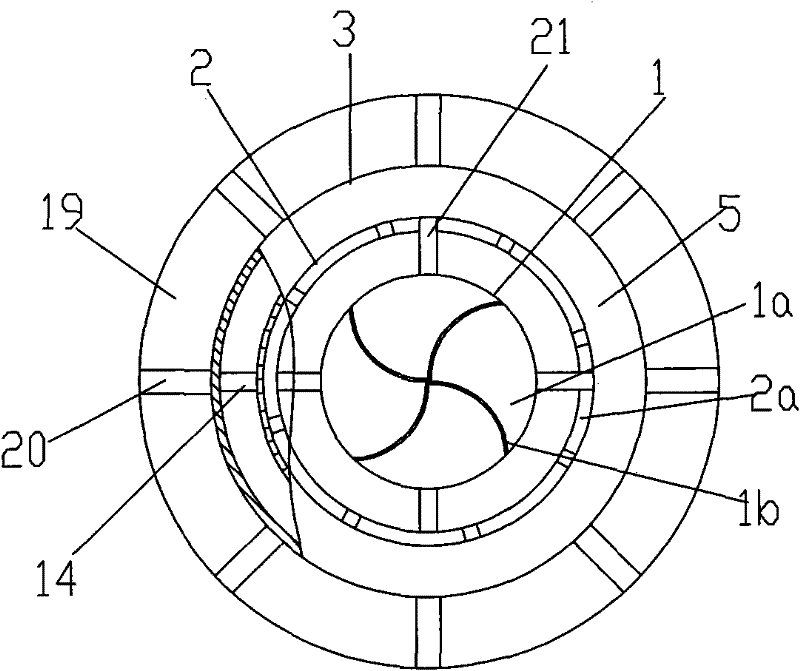

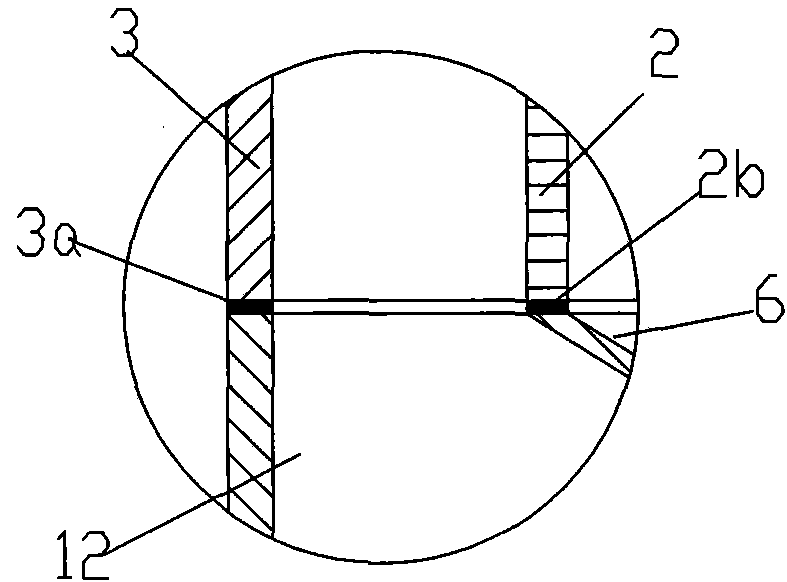

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 View along direction A, image 3 for figure 1 The enlarged view at B, as shown in the figure: the raw coal centrifugal dehydrator for coal mine in this embodiment includes a centrifugal dehydration assembly and a driving device;

[0021] The centrifugal dehydration assembly includes a housing 3, a liquid rejection cylinder 2 and a material rejection tray 1. The material rejection tray 1 is driven along the axis to cooperate with a dehydration power input shaft 16, and the liquid rejection cylinder 2 is coaxially fixed on the spinner The outer circle of the material tray 1, the material passing channel is formed between the inner surface of the liquid rejection cylinder 2 and the outer surface of the material rejection tray 1; An interlayer is formed between the outer circular surfaces of the liquid rejection cylinder 2; the wall of the liquid rejection cylinder 2 is a siev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com