Method for attaching micro bubble array on plate surface

A solid surface, micro-bubble technology, applied in the direction of the hull, hull design, fluid flow, etc., can solve the problems of driving force reduction, erosion, etc., and achieve the effect of reducing flow friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

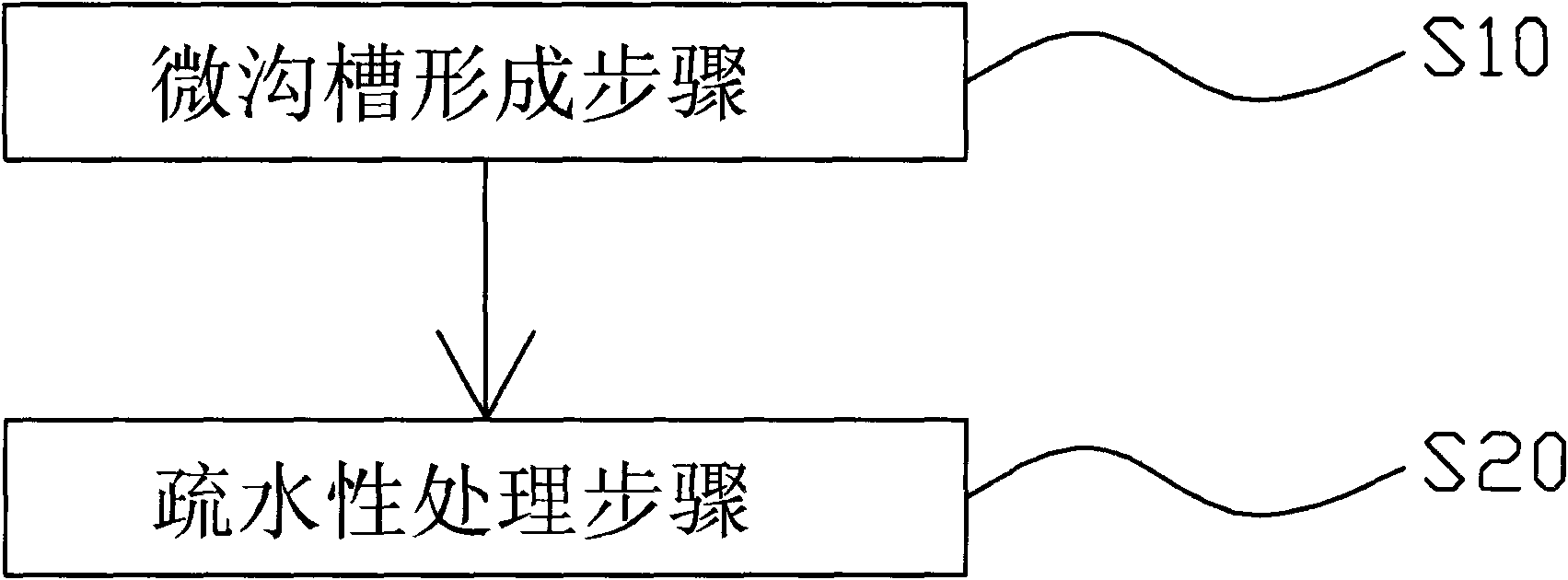

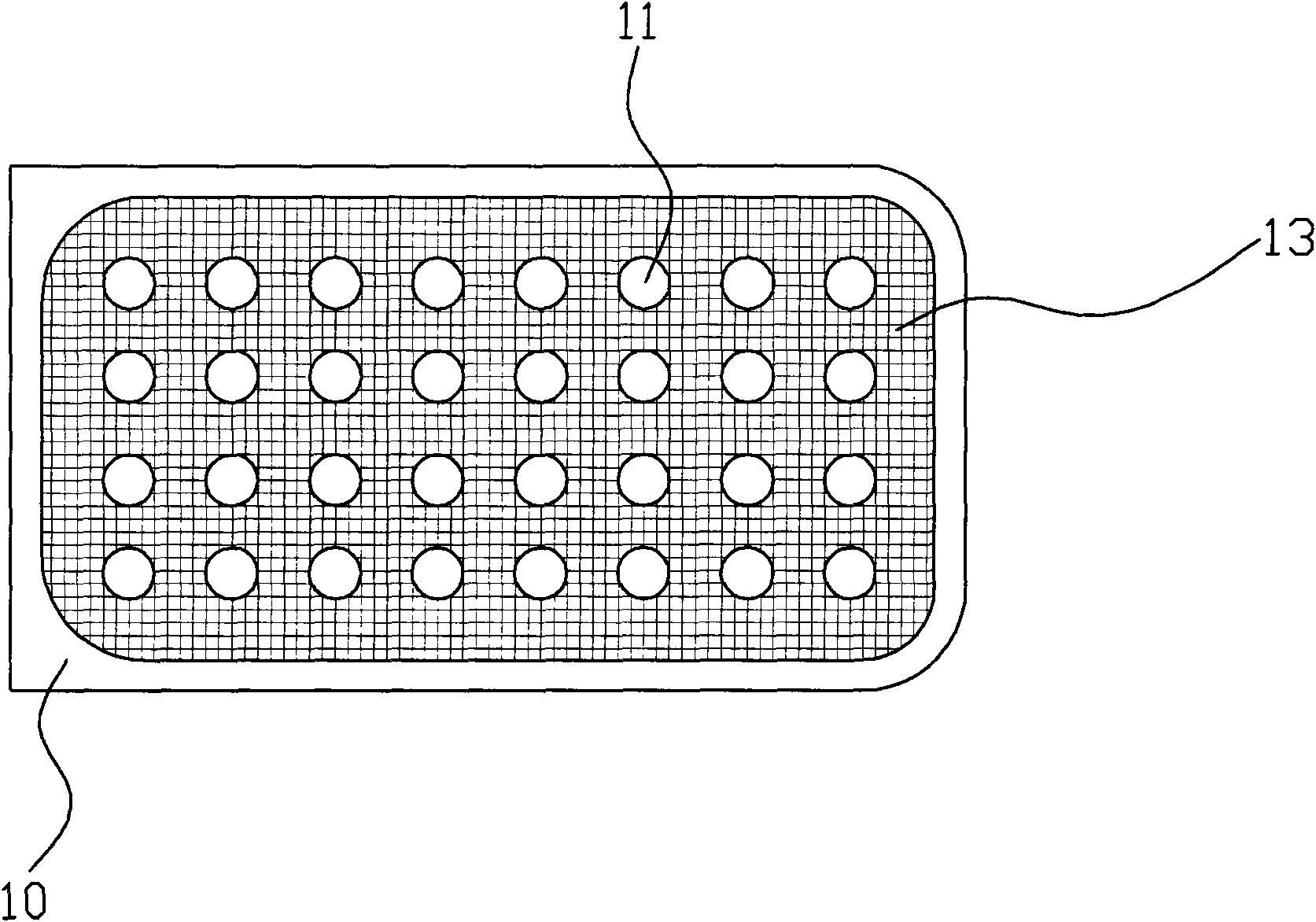

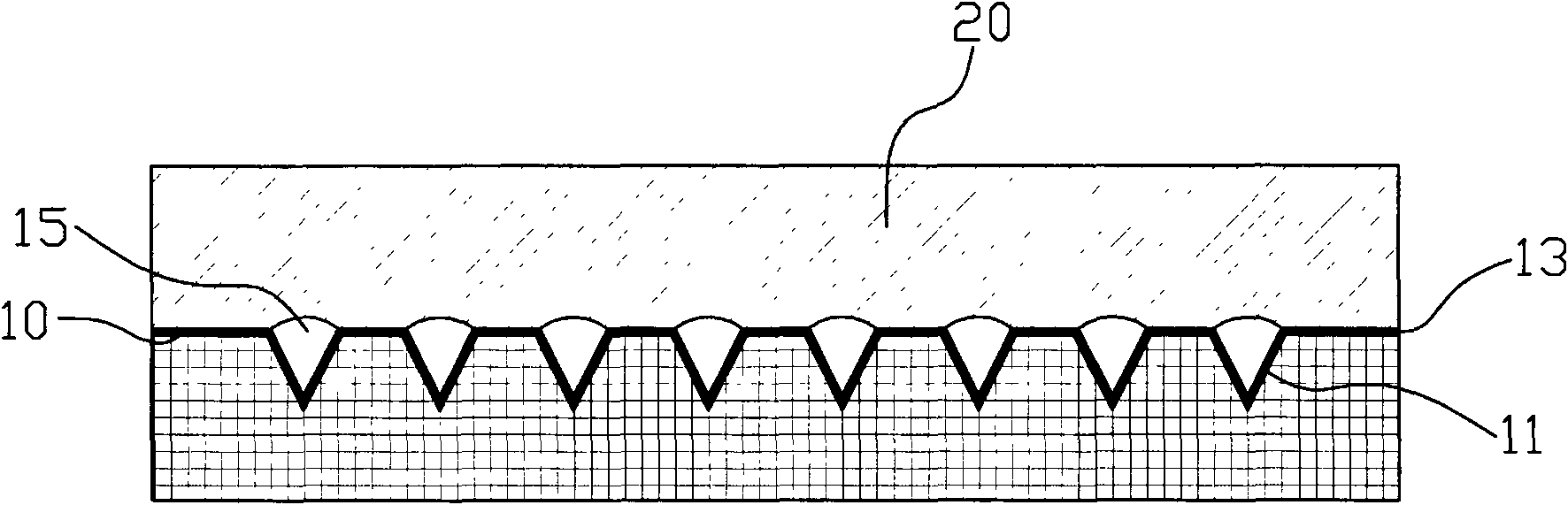

[0033] figure 1 is a schematic view showing a method for forming fine air bubbles on a solid surface according to an embodiment of the present invention, figure 2 Yes means applicable to figure 1 Schematic representation of the solid surface of the illustrated embodiment, image 3 yes means figure 2 The shown cross-sectional view of the solid surface placed in water.

[0034] refer to Figures 1 to 3 An example of the method for forming fine air bubbles on a solid surface according to the present invention will be described.

[0035] The method for forming fine air bubbles on a solid surface includes a micro-groove forming step S10 and a hydrophobic treatment step S20.

[0036] The micro-groove forming step S10 is a step of forming grooves 11 on the solid surface, so that grooves with a size of 1-1000 μm are arranged on the solid surface 10 . The cross-sectional shape of the groove 11 can be various shapes such as quadrangle, triangle, trapezoid and circle.

[0037] T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap