Method for realizing fast disassembling and assembling of threaded connection

A threaded connection and threaded technology, which is applied in the direction of connecting components, threaded fasteners, nuts, etc., can solve the limitation of flexibility, the lengthening of the disassembly and assembly time of two parts or parts, and the unsuitability of two parts or parts for quick connection and Detachment and other problems, to achieve the effect of quick connection and detachment, quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

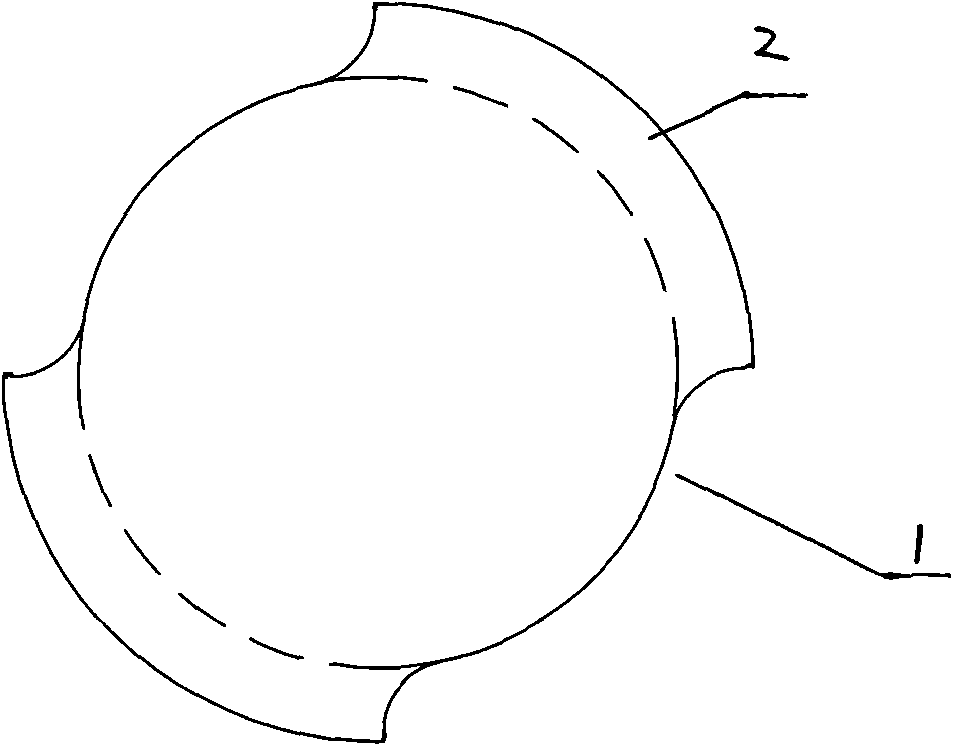

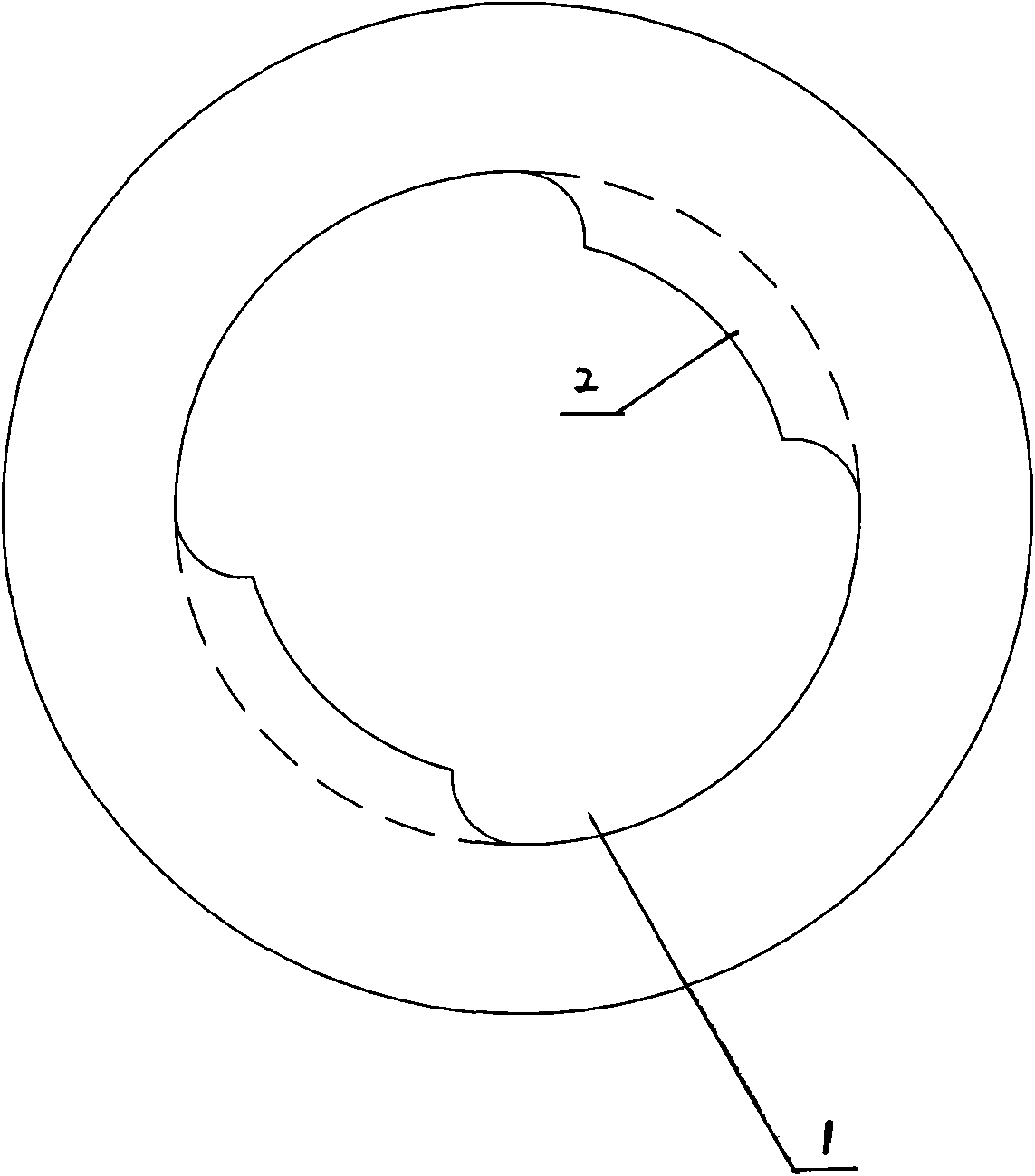

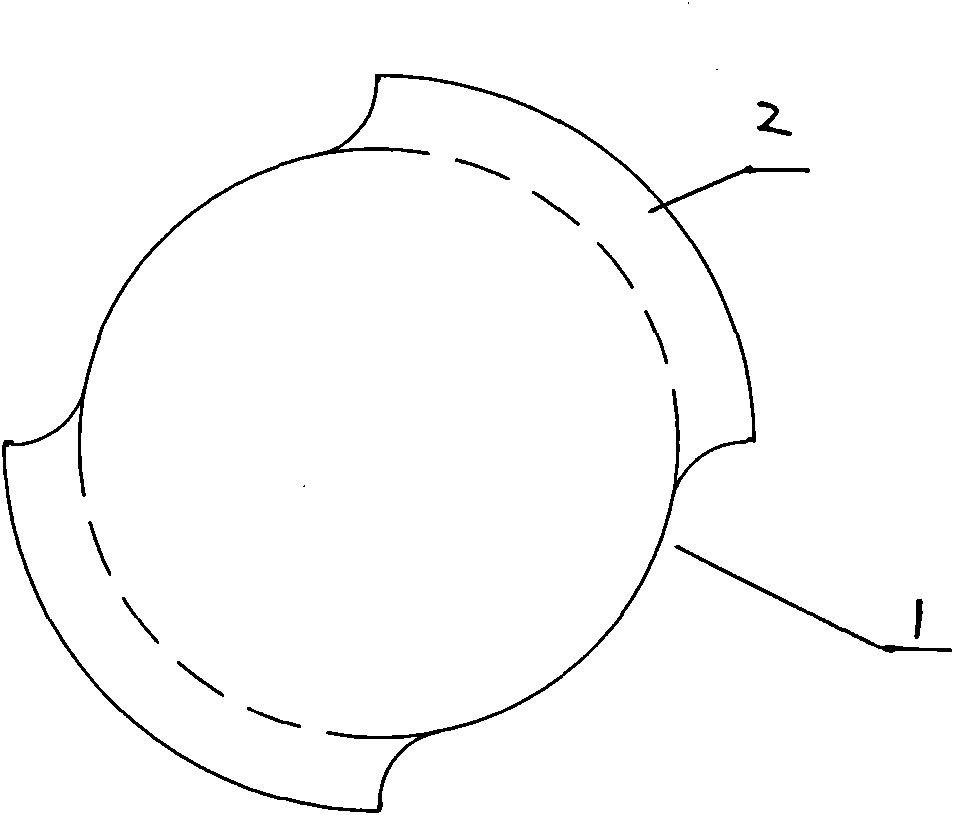

[0010] A threaded connection method for realizing quick disassembly and assembly, including internal threads and external threads that cooperate with each other, a thread passing groove 1 is arranged axially on the thread mating surface, and the thread passing groove 1 and the remaining threaded part 2 are evenly spaced in the circumferential direction .

[0011] The thread passing groove 1 can be made by removing part of the thread through axial machining on the basis of the original thread mating surface.

[0012] The thread passing grooves 1 are preferably arranged diagonally, and each thread passing groove accounts for a quarter of the circumference of the thread mating surface. Each thread passing groove can also adopt other dimensions, as long as it is evenly spaced circumferentially from the rest of the threaded portion.

[0013] As shown in the figure, the thread processing of two quarters of the diagonal part of the screw is removed, and only two quarters of the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com