Tube plate absorber welded with pressure tank aluminum strips

A technology of absorber and pressure groove, which is applied in welding equipment, non-electric welding equipment, solar heating equipment, etc., can solve the problems of time-consuming, long-term mold fixing time, and destruction of selective absorption film, etc., to achieve firm connection and welding deformation Small, low heat transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

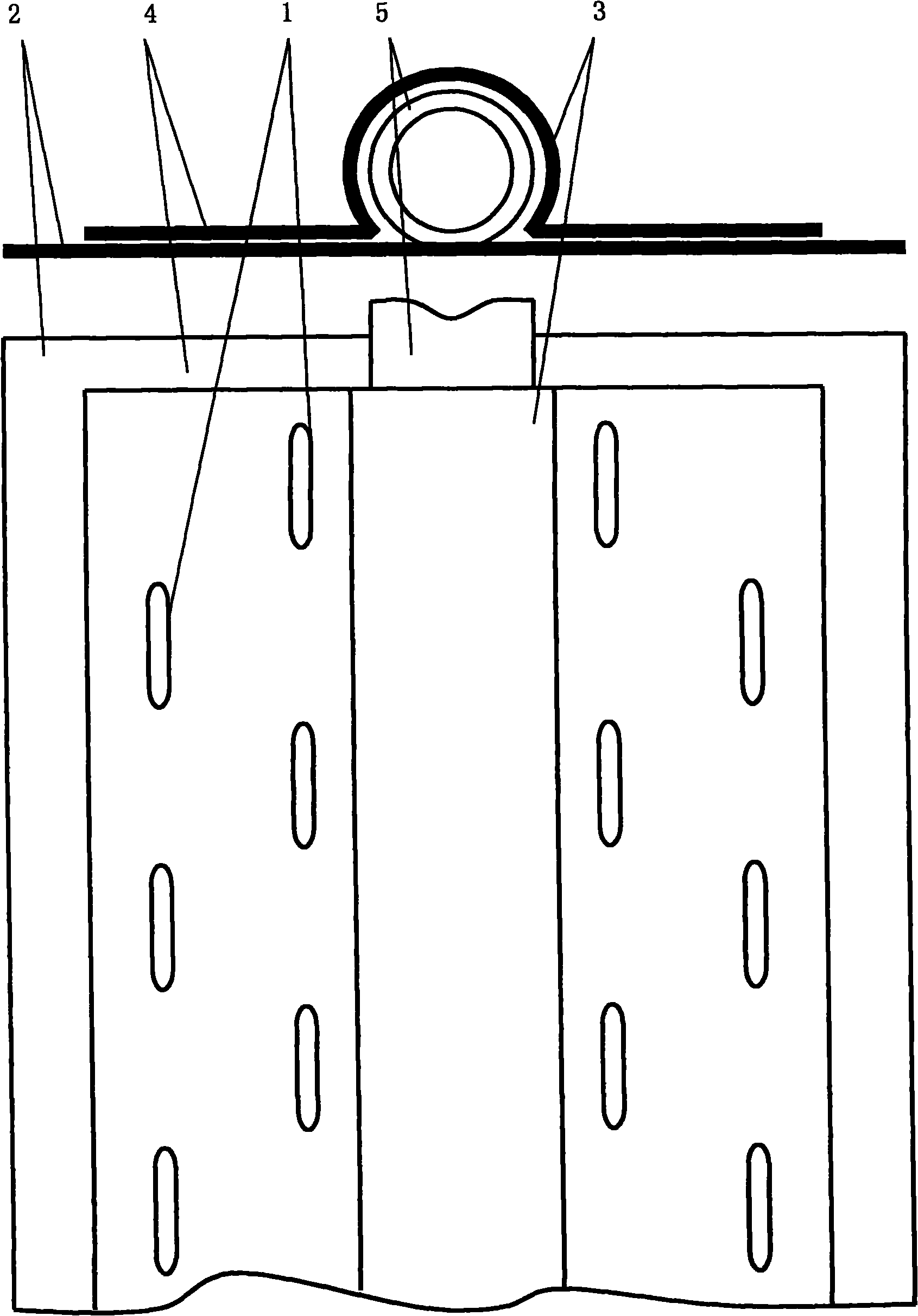

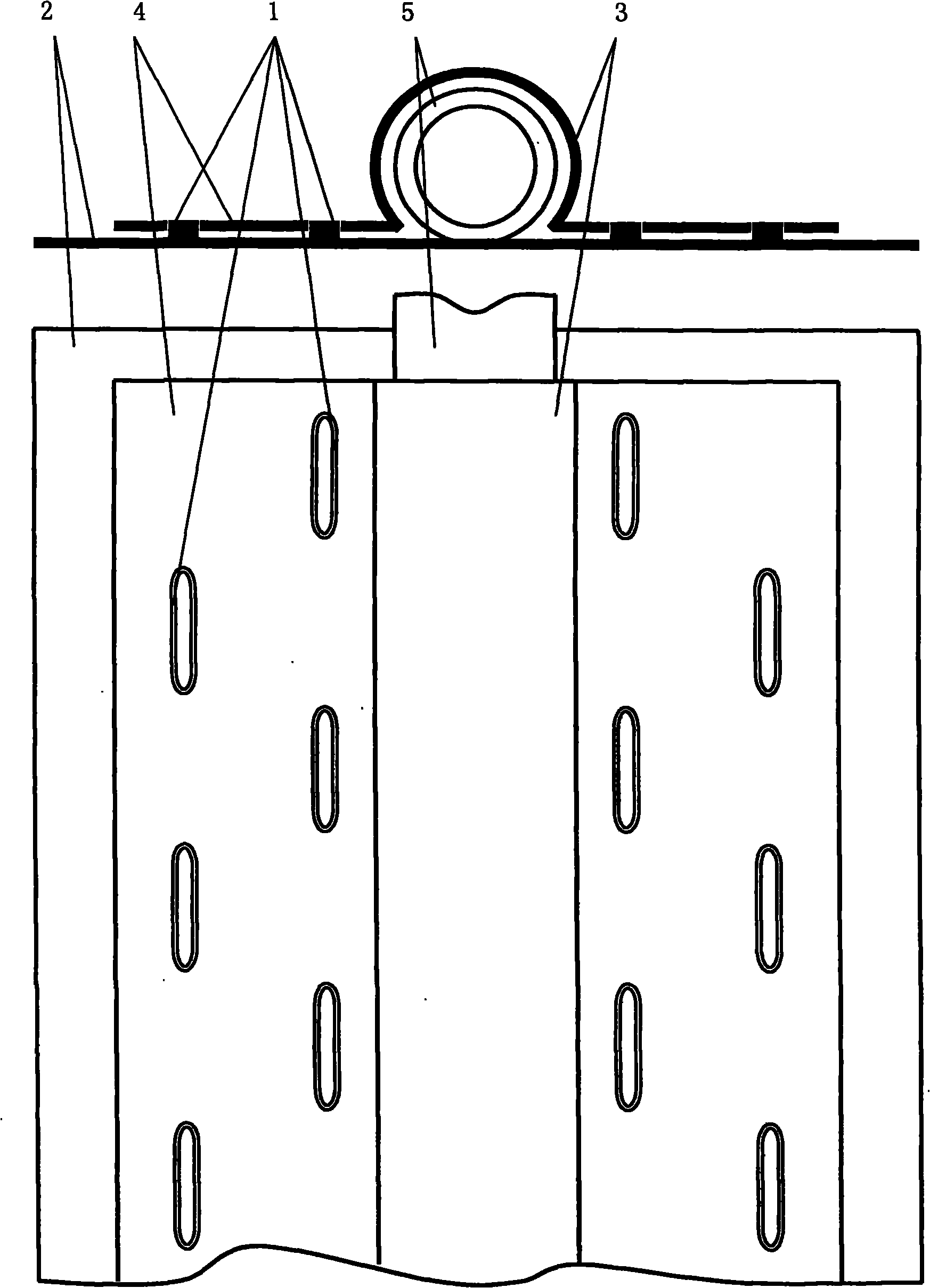

[0009] figure 1 An embodiment of the present invention is given, a tubesheet absorber of welded grooved aluminum strips. figure 1 Among them, a rectangular aluminum plate absorber 2 with a slender convex groove 1 on the back is matched with a grooved aluminum strip 3 with a slender hole matching the aluminum plate absorber convex groove 1, and the two are matched. Welding, and then embed the elastic pipe 5 in the groove to make a tube sheet absorber for welding the grooved aluminum strip. The two flanges 4 of the grooved aluminum bar 3 are respectively provided with two rows of elongated holes arranged at intervals.

[0010] The design of two rows of slender holes arranged at intervals on the two flanges of the grooved aluminum strip 3 can minimize the harmful stress generated by the slender holes and allow the workpiece to slide over the assembly line during welding to keep the welding torch The position does not move.

[0011] Furthermore, ultrasonic welding facilities ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com