High-strength prestress rare earth coating steel wire stabilization production technology

A production process, prestressing technology, applied in hot dip plating process, metal material coating process, coating and other directions, can solve the problems of rare earth coating melting, product performance can not meet low relaxation and elongation, etc., to achieve toughness index increase , optimize mechanical properties, ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

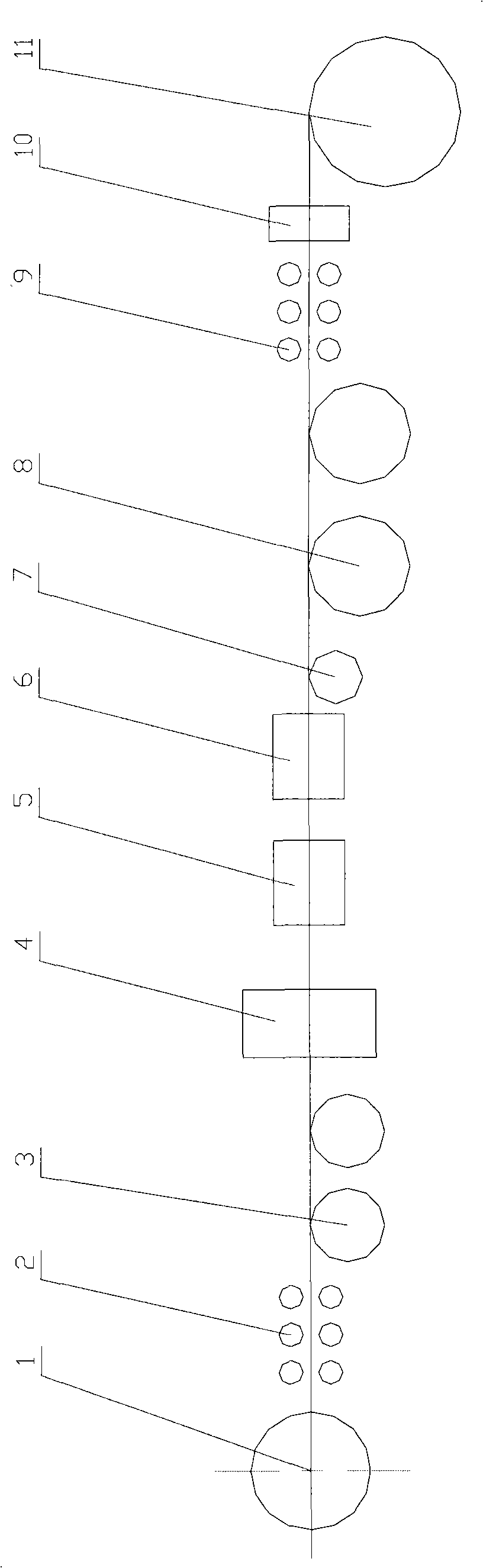

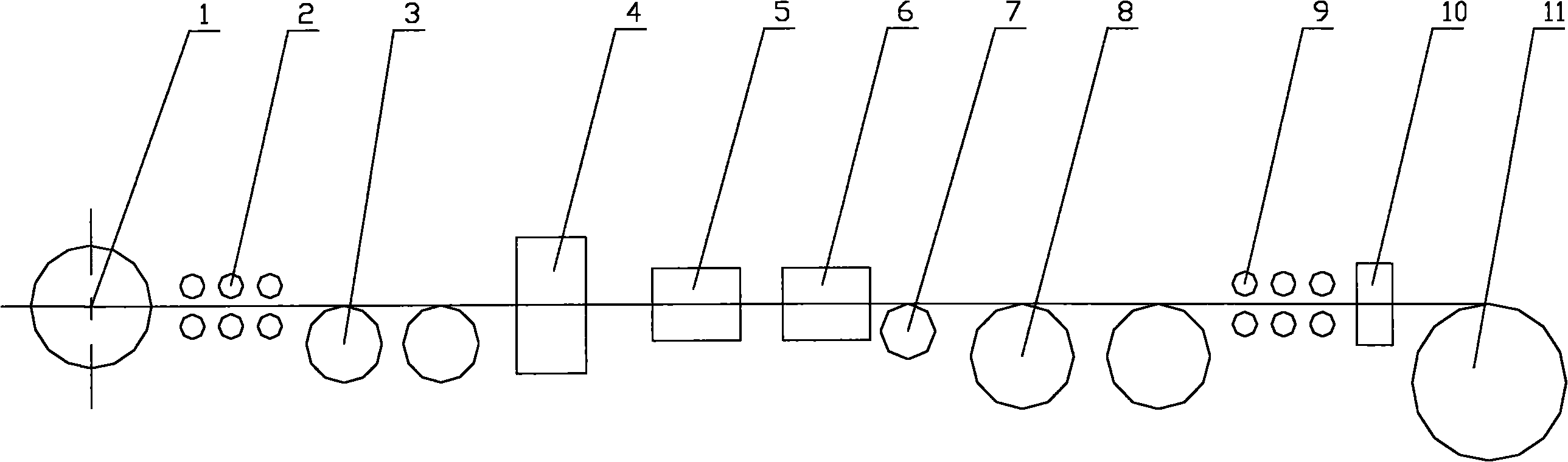

[0013] The embodiment, as shown in the figure, includes: flower basket unwinding 1, straightening 2, first tensioning wheel set 3, smoothing die 4, intermediate frequency furnace 5 tempering, cooling tank 6 cooling, force measuring wheel 7, second Tensioning wheel set 8, traction machine 9, shearing machine 10 shear, and take-up machine 11 forms a coil.

[0014] The tempering temperature of the intermediate frequency furnace 5 is 360-370°C.

[0015] The steel wire passes through the flower basket pay-off machine 1, passes through the straightener 2, enters the first tensioning wheel group 3, enters the intermediate frequency furnace 5 for medium temperature tempering after finishing the mold 4, and then enters the cooling tank 6 for cooling, and then passes through the The force-measuring wheel 7 and the second tensioning wheel group 8 are drawn into the shearing machine 10 by the tractor 9, and then enter the wire take-up machine 11 into coils through shearing.

[0016] This...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap