Tray used for vertically continuous delivery of solid material

A technology for solid materials and pallets, which is applied in the direction of fillings, safety devices, mining equipment, etc., can solve problems such as bending deformation, work accidents, failures, etc., and achieve the effects of strong bearing capacity, high reliability, and increased wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

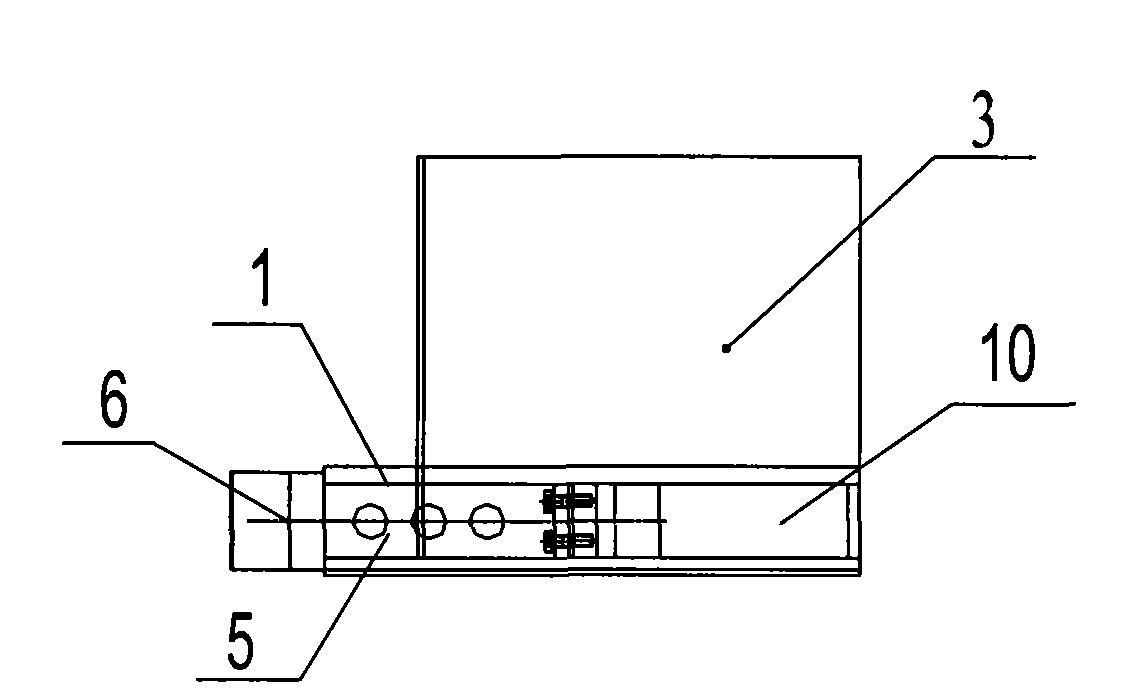

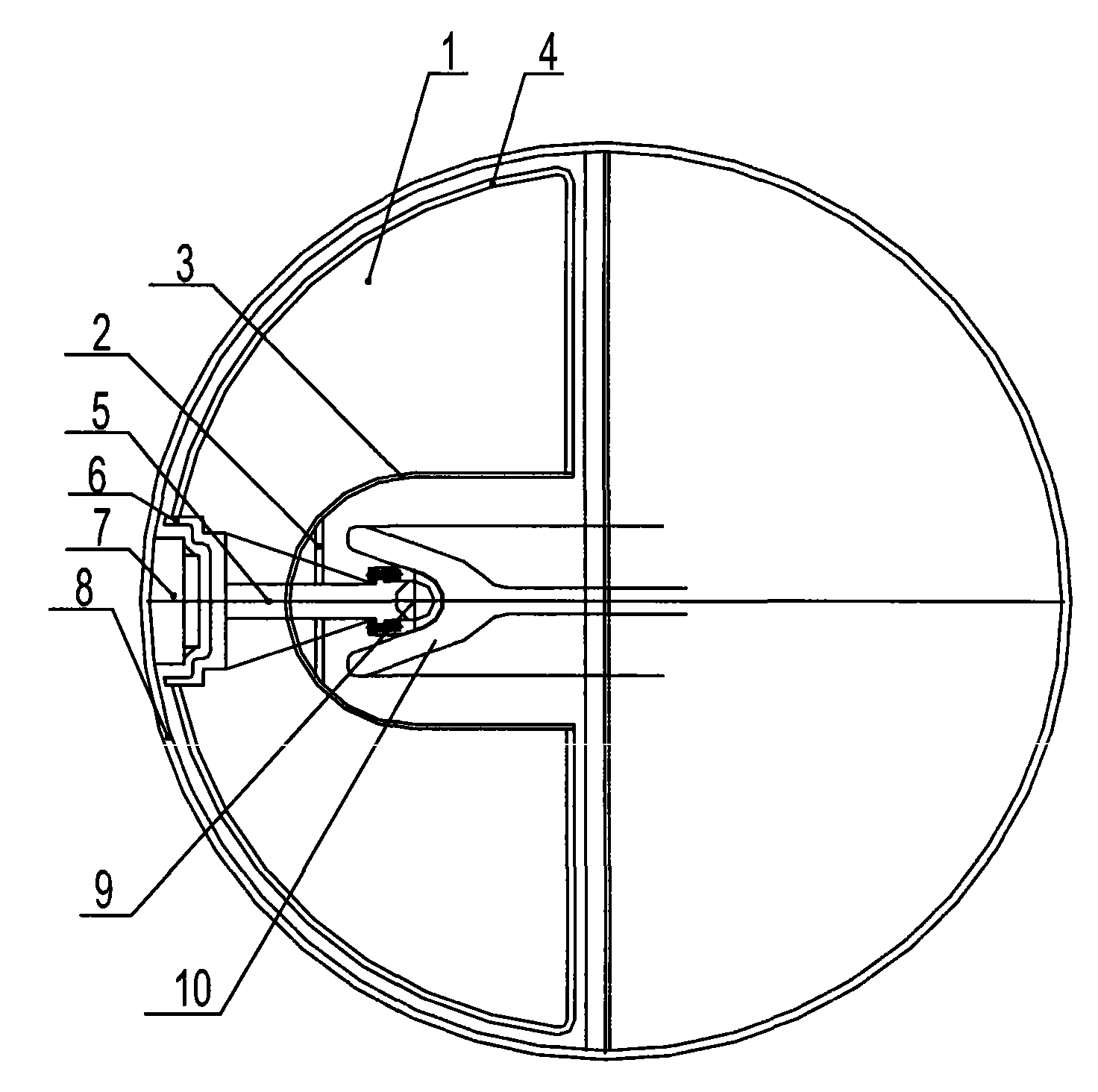

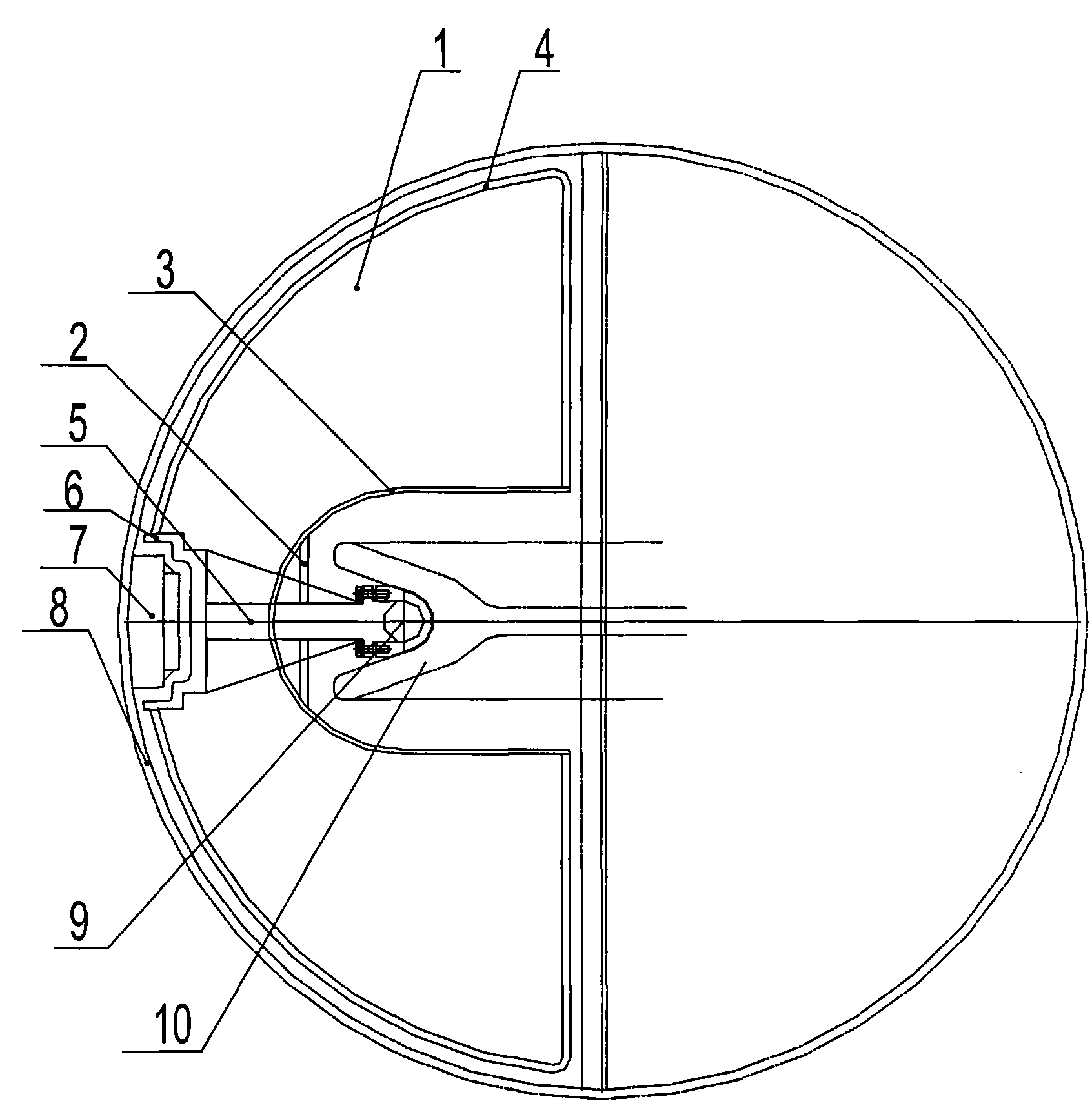

[0011] As shown in the accompanying drawings, the tray used for vertical and continuous delivery of solid materials is in the shape of a fan, and is mainly composed of a semicircular bottom plate 1, a reinforcement plate 2, a guard plate 3, a baffle plate 4, a support frame 5 and a guide plate 6. The semicircular bottom plate 1 carries solid materials, and the middle part of the inner side has a semicircular arc-shaped groove at the bottom that is compatible with the wire rope slideway 10. The bottom plate 1 has a rectangular groove that is compatible with the slideway 7. The bottom of 1 is provided with the support frame 5 whose head is fixed on the wire rope 9, the rear part of the support frame 5 is provided with the guide plate 6 that slides with the slideway 7, the guide plate 6 is welded on the edge of the bottom plate, and the guide plate 6 is on t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap