Water-injecting and resealing mechanism of fast food

A food and instant food technology, which is applied in the direction of coin-operated equipment, instruments, coinless or similar appliances for distributing discrete items, etc., can solve the problems of food contamination, no cover of the cup mouth, inconvenient to carry, etc., to ensure portability Sexuality, avoiding food contamination, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

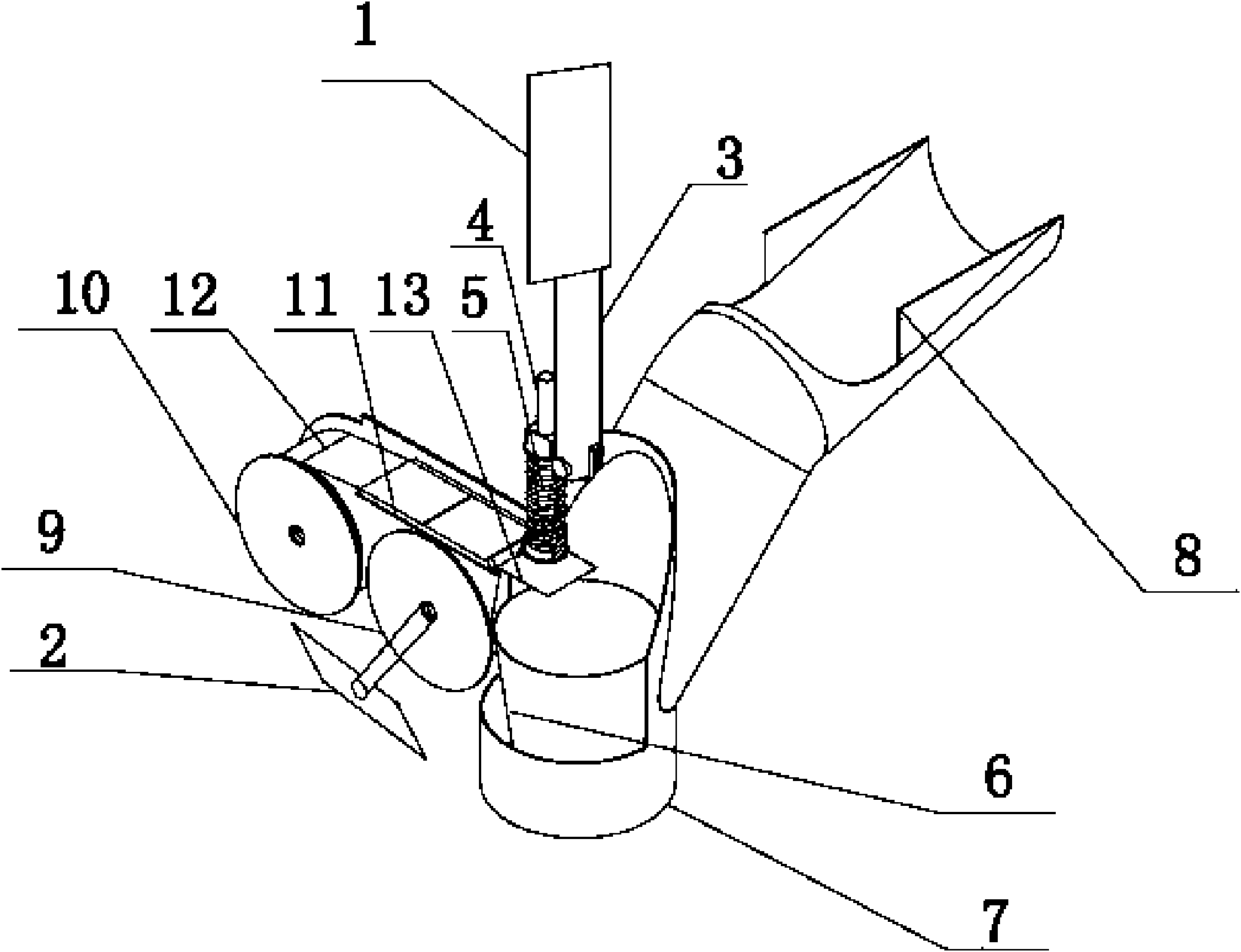

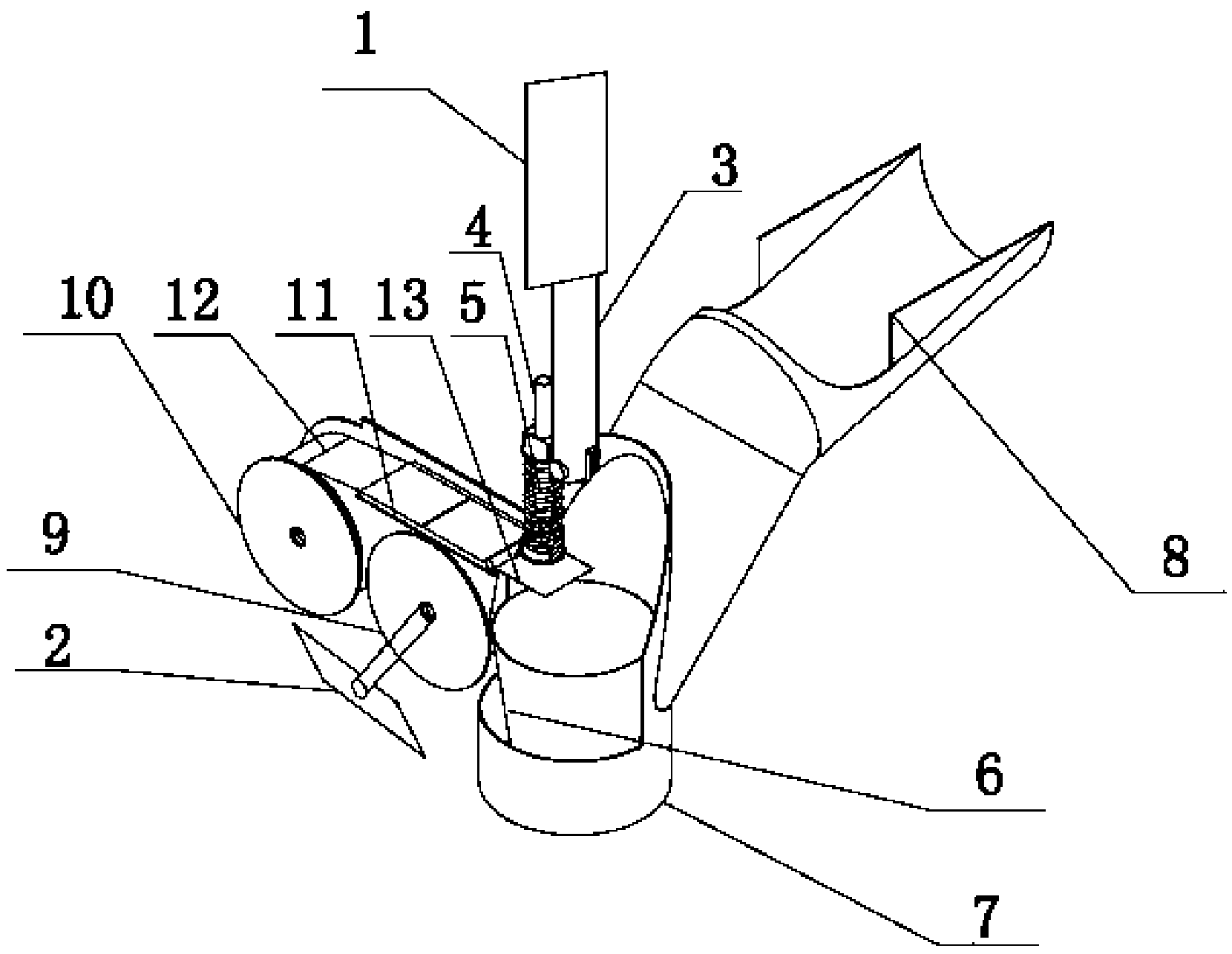

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, the packaging mechanism of this embodiment includes a first motor 1, a second motor 2, a first shaft 3, a water injection pipe 4, an elastic element 5, a bracket 7, a slideway 8, a first rotating shaft 9, and a second rotating shaft 10. Bottom plate 11, ring-shaped label tape 12 and label 13, the output shaft of the first motor 1 is connected to one end of the first shaft 3, the other end of the first shaft 3 is connected to one end of the water injection pipe 4, and the water injection pipe 4 The upper sleeve is provided with an elastic element 5, and the elastic element 5 is arranged opposite to the packaging box 6 and is located above the packaging box 6. The packaging box 6 is arranged in the bracket 7 and is arranged up and down opposite to the water injection pipe 4. The brackets 7 are respectively It is fixedly connected with the slideway 8 and the bottom plate 11, and the output shaft o...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 The present embodiment will be described, and the elastic member 5 of the present embodiment is a spring. Other components and connections are the same as those in the first embodiment.

[0009] working principle:

[0010] After the packaging box 6 with food falls into the slideway 8 and slides onto the support 7, the first motor 1 drives the first shaft 3 to drive the water injection pipe 4 to move down a larger stroke and puncture the packaging box 6, then to the Fill the packing box 6 with water. After the water injection is completed, the water injection pipe 4 moves upwards for a certain distance, and the second motor 4 drives the first rotating shaft 9 to rotate and drives the second rotating shaft 10 to rotate through the annular label belt 12, so that the label 13 is aligned with the label. The belt 12 separates and falls on the opening of the packaging box 6, the first motor 1 drives the first shaft 3 to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap