Hot chamber sampling device

A sampling device and hot cell technology, which is applied in the field of nuclear fuel reprocessing hot cell sampling devices, can solve the problems of complex structure, high labor intensity, and inability to achieve simultaneous sampling of the sampling device, so as to reduce the risk of radioactive contamination, reduce the difficulty and Safe and reliable effect of frequency of use and sampling operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

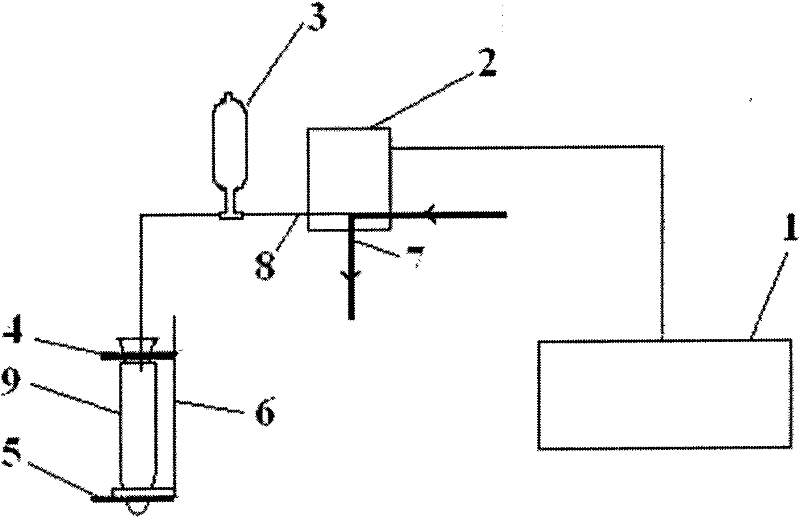

[0016] Hot cell sampling device such as figure 1 As shown, the device includes a solenoid valve controller 1, a three-way solenoid valve 2, a sample tube 9, a stand 6 and a sampling tube 8, and the three-way solenoid valve 2 and its solenoid valve controller 1 are used to open or close the sampling pipeline , wherein the three-way electromagnetic valve 2 is connected to the experimental liquid flow pipeline 7 that needs to be sampled, and the opening and closing of the three-way electromagnetic valve 2 is controlled by the electromagnetic valve controller 1 arranged outside the heat chamber to realize the control of the direction of the liquid flow; three A vent pipe 3 is arranged on the sampling pipe 8 between the solenoid valve 2 and the sample pipe 9, and its function is to introduce atmospheric pressure into the sampling pipe, so that the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com