Box type wire descaling machine

A technology of peeling and shelling machine and wire coil, which is used in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as personal injury and environmental pollution, and achieve the effects of high work efficiency, convenient use and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

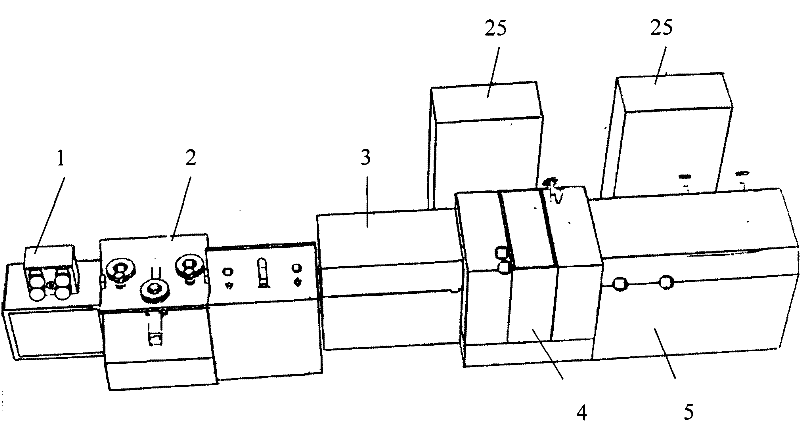

[0028] Such as figure 1 As shown, the box-type coil wire oxide skin peeling machine is composed of a feeding part 1, a shelling part 2, a derusting part 3, a cleaning part 4 and a cleaning part 5;

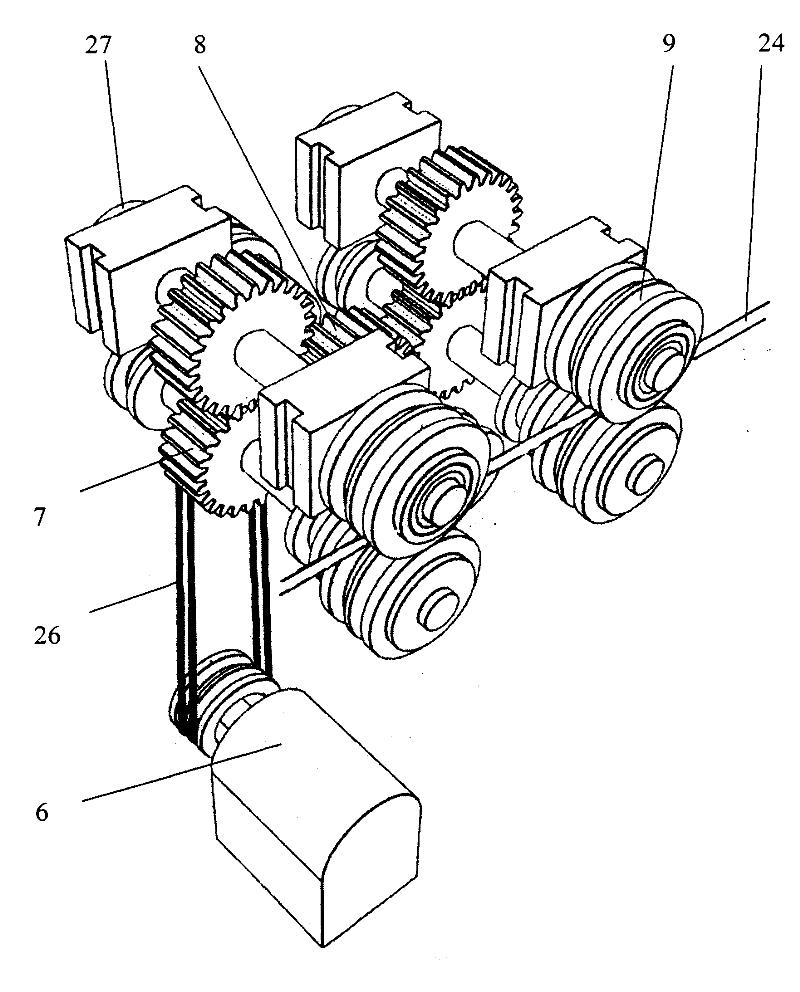

[0029] Such as figure 2 As shown, the feeding part 1 is composed of a feeding motor 6, a feeding gear 7, an intermediate gear 8 and a feeding roller 9. There are two groups of the feeding gear 7 and the feeding roller 9. The feeding roller 9 is connected with the feeding gear 7 through a rotating shaft. The feeding motor 6 The belt 26 is connected with the intermediate gear 8, and the intermediate gear 8 is connected with two groups of feeding gears 7; the feeding rollers 9 of the same group are close to each other through the adjustment handle 27, so as to clamp the wire 24;

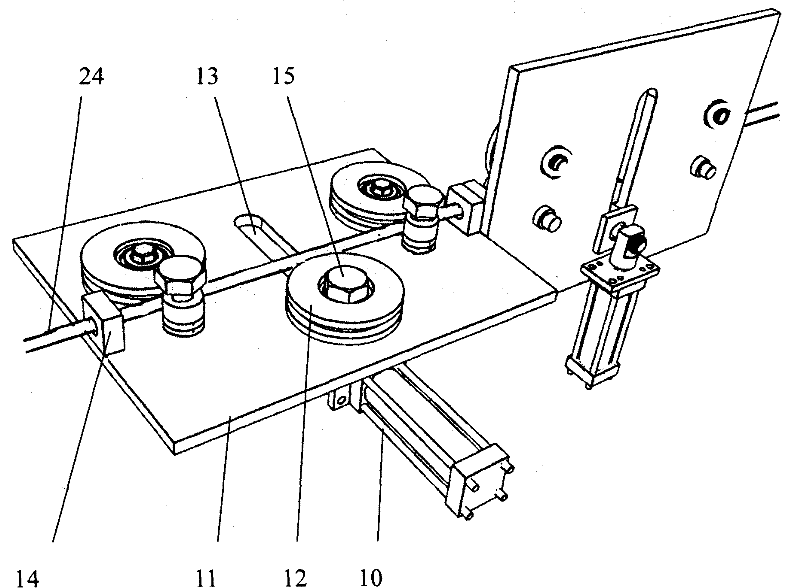

[0030] Such as image 3 As shown, the peeling part is divided into two groups, and each group is composed of a top cylinder 10, a fixed plate 11 and a shelling roller 12, and each group of shelling parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com