Corrosion inhibitor for engine coolant and preparation method thereof

A technology for engine coolant and corrosion inhibitor, which is applied in the field of metal material anti-corrosion, can solve the problems of complex synthesis process, high preparation cost, incomplete protection, etc., and achieves the effects of abundant raw material sources, low production cost and good protection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

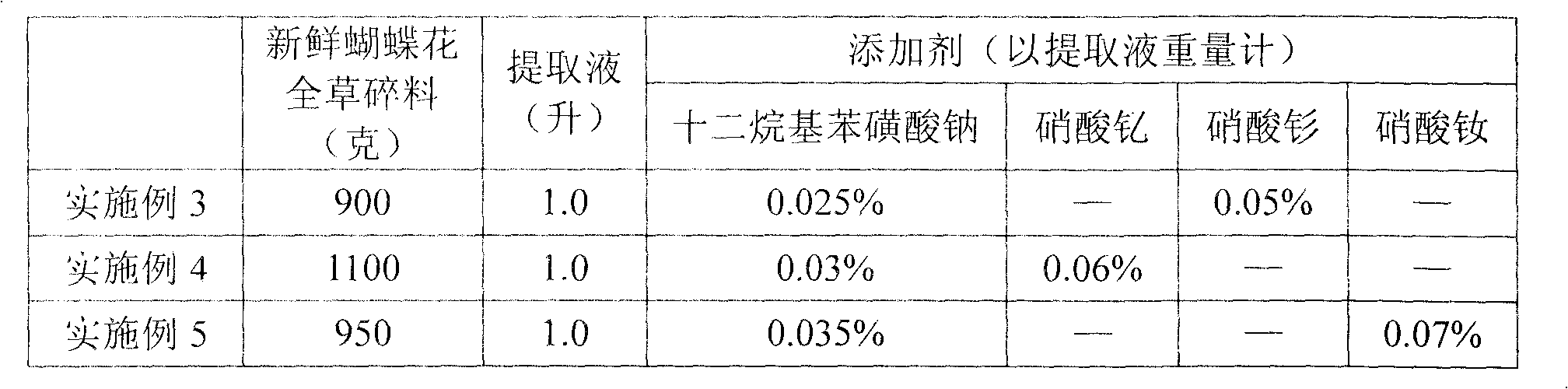

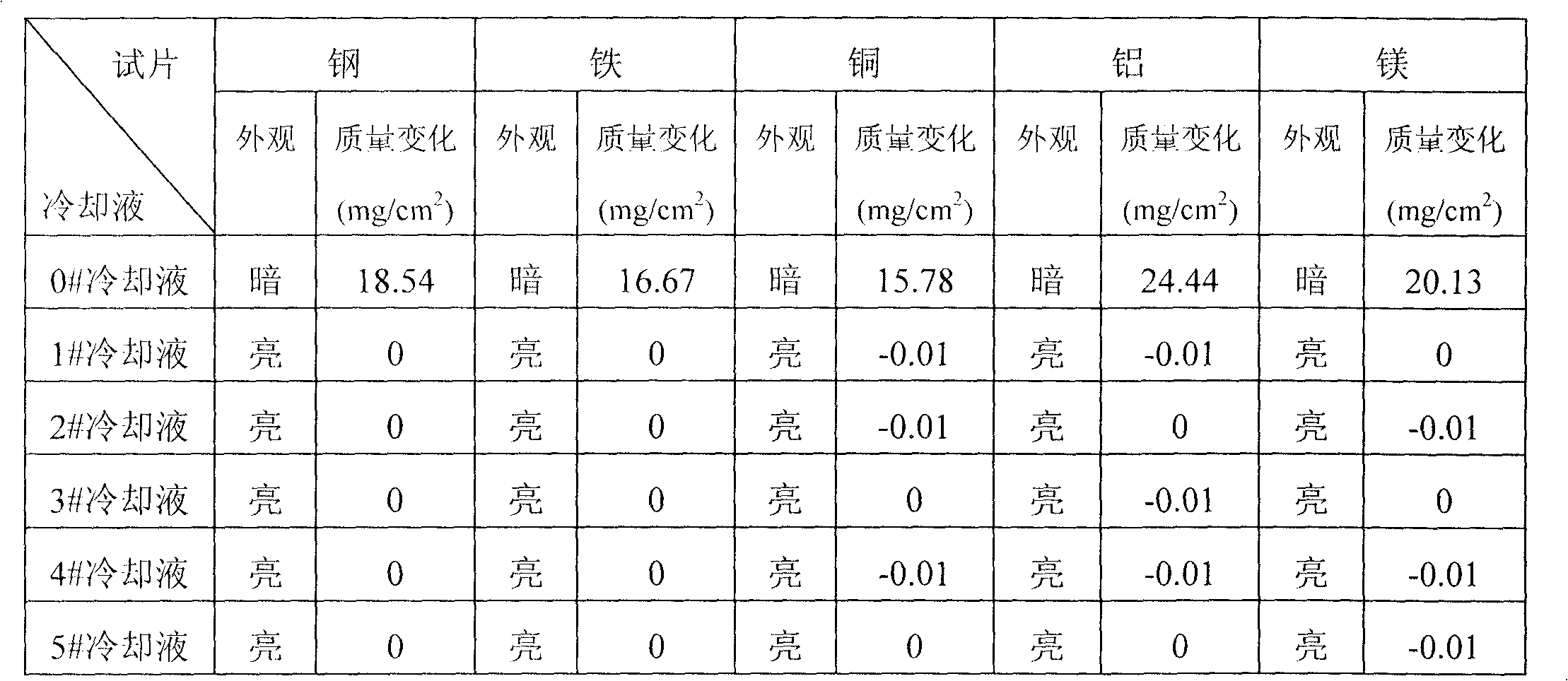

Examples

Embodiment 1

[0018] The specific steps of a method for preparing a corrosion inhibitor for engine coolant are as follows:

[0019] ① Preparation of extract

[0020] Get about 500 grams of fresh pansy flower whole grass scraps, add about 5 liters of water (about 10 times the weight of the whole pansy pansy), carry out ultrasonic-assisted leaching at 85 ° C for 2 hours, cool, stand still, filter, filter The cake repeats the above operation once, collects the extracted crude liquid twice, heats and concentrates to about 0.5 liters, and obtains an extract (equivalent to the whole herb extract of pansies contained in every liter of extract, calculated according to the raw material of whole herb of pansies). 1000 grams).

[0021] ② Preparation of corrosion inhibitor

[0022] Add additives sodium dodecylbenzenesulfonate and lanthanum nitrate to the extract prepared in step ①, stir to mix evenly, and obtain a corrosion inhibitor for engine coolant. Wherein, the addition of sodium dodecylbenzene...

Embodiment 2

[0024] The specific steps of a method for preparing a corrosion inhibitor for engine coolant are as follows:

[0025] ① Preparation of extract

[0026] Get about 500 grams of fresh pansy flower whole grass fragments, add about 3 liters of water (about 6 times the weight of the whole pansy pansy), carry out ultrasonic-assisted leaching at 70 ° C for 1 hour, cool, stand still, filter, filter Cake repeats above-mentioned operation 2 times, collects the extraction thick liquid of three times, heats and concentrates to about 0.5 liters, makes extracting liquid (equivalent to the whole plant extract of Pantera japonica contained in every liter of extracting liquid, calculates 1000 by fresh whole plant of Pantera japonica raw material. gram).

[0027] ② Preparation of corrosion inhibitor

[0028] Add additives sodium dodecylbenzene sulfonate and cerium nitrate to the extract prepared in step ①, stir to mix evenly, and obtain a corrosion inhibitor for engine coolant. Wherein, the a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap