Intelligent injection allocation process of water injection well

An intelligent and technological technology, applied in the direction of wellbore/well components, production fluids, instruments, etc., can solve the problems of increased testing workload and achieve the effects of saving conventional production testing costs, avoiding production testing, and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

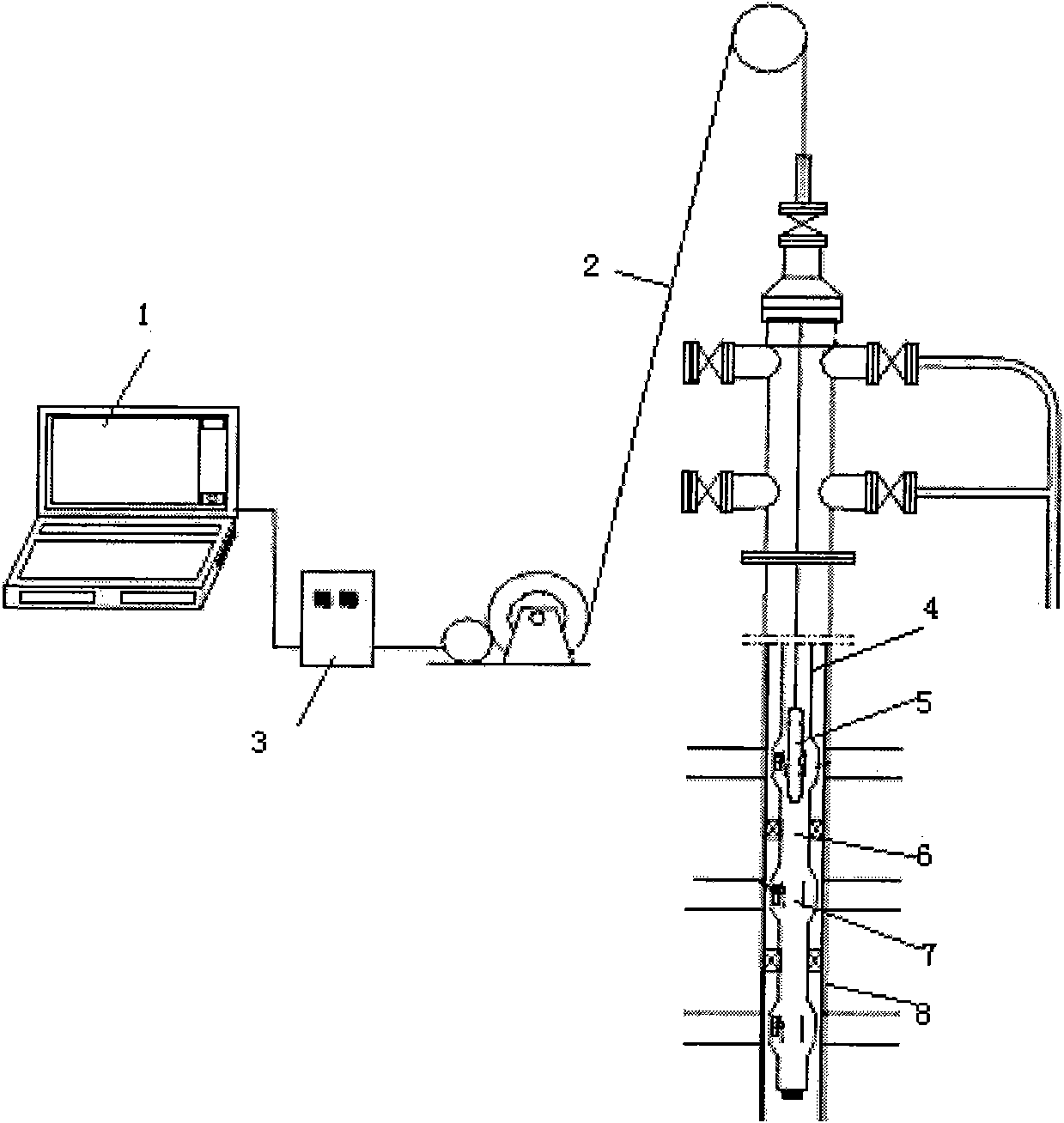

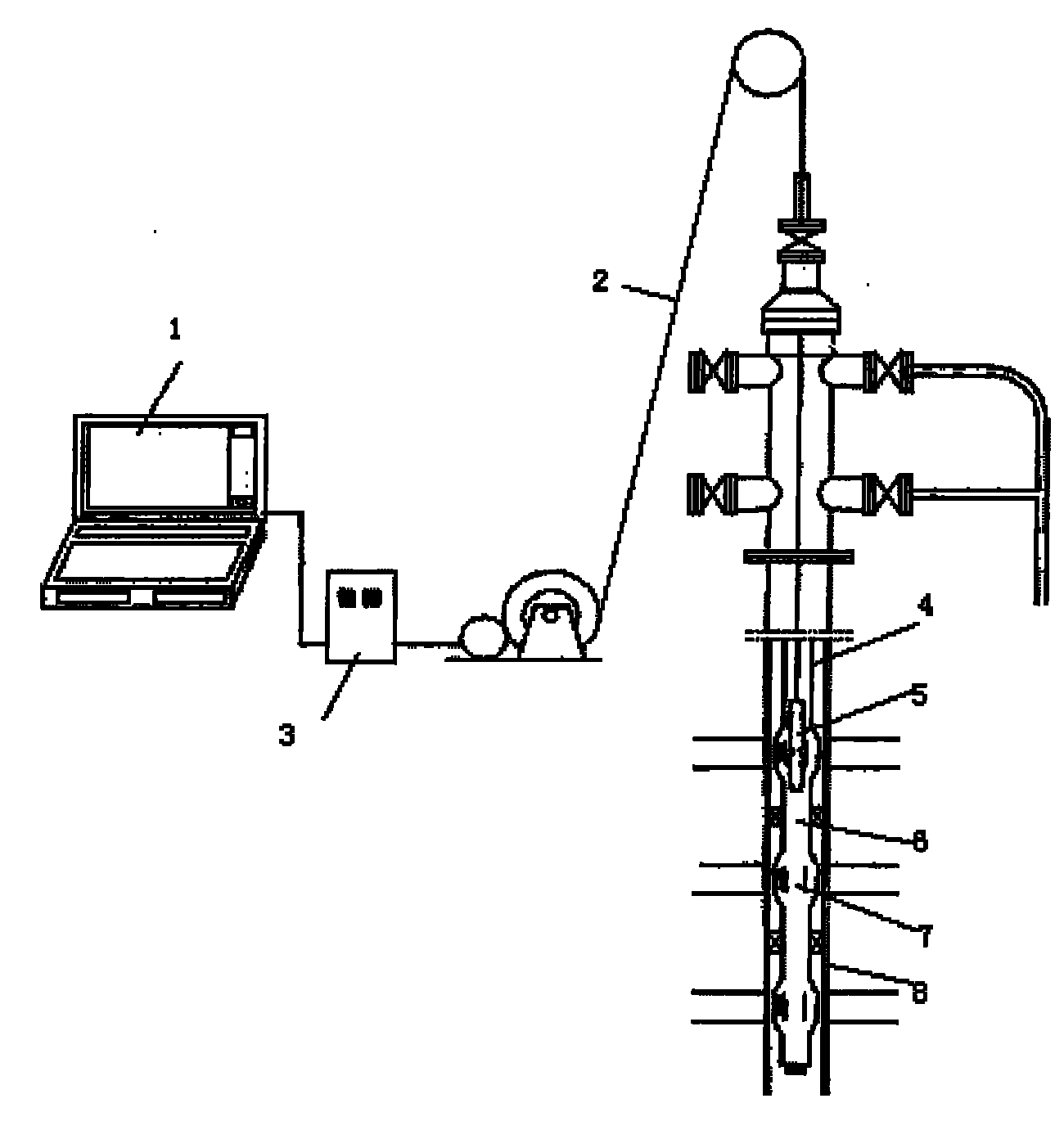

[0013] Below in conjunction with accompanying drawing, the present invention is further described: it is made up of computer 1, power cable 2, control main engine 3, oil pipe 4, dispensing instrument 5, packer 6, intelligent water distribution device 7 and bushing 8; wherein power cable 2 The upper end is connected to the control host 3, and the lower end is connected to the dispensing instrument 5. The intelligent dispensing instrument 5 is lowered into the intelligent water distribution device 7. The oil pipe 4 is connected to the packer 6 through a screw thread, and the packer 6 and the intelligent water distribution device 7 pass through. Threaded connection, oil pipe 4, packer 6 and intelligent water distribution device 7 have casing 8 outside; this process is realized through the following steps:

[0014] a. First, connect the tubing 4, packer 6, and intelligent water distribution device 7 and run them into the casing 8. At the same time, each intelligent water distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com