Method for preparing lead and lead alloy metallic phase samples and exposing texture

A technology for metallographic samples and alloys, which is applied in the preparation of metallographic samples of lead and its alloys and microstructure exposure experiments, in the field of preparation of metallographic samples of lead and its alloys, can solve the cost of consumables, working time and the sample preparation process Satisfactory, etc., to avoid surface tissue deformation, reveal high definition, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

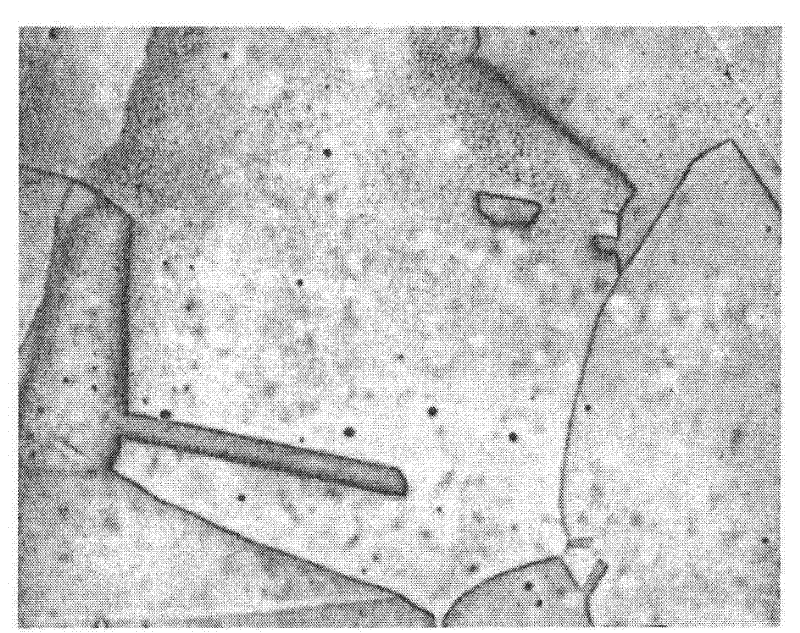

[0026] A piece of sample with a specification of 20mm×20mm was cut with a manual hacksaw on an industrial pure lead ingot. The specific implementation steps are as follows:

[0027] a. Wet grinding: the sample is first polished with a fine-toothed flat file, using flowing water as a coolant and lubricant, and then mechanically polished;

[0028]b. Mechanical polishing: put the wet-ground sample in water containing detergent, wash it in an ultrasonic vibration cleaner, and then perform mechanical polishing for about 2 minutes: the polishing speed is 200r / min; at this time, the polishing liquid is both a coolant and a Lubricant: Spray chromium oxide with a particle size of 0.5 μm on the microporous fabric polishing flannelette, mix it into water and stir the suspension evenly as a polishing liquid, polish the sample, observe the surface state of the sample under a microscope, and confirm that the surface of the sample is scratched by a file. Chemical polishing after the marks d...

example 2

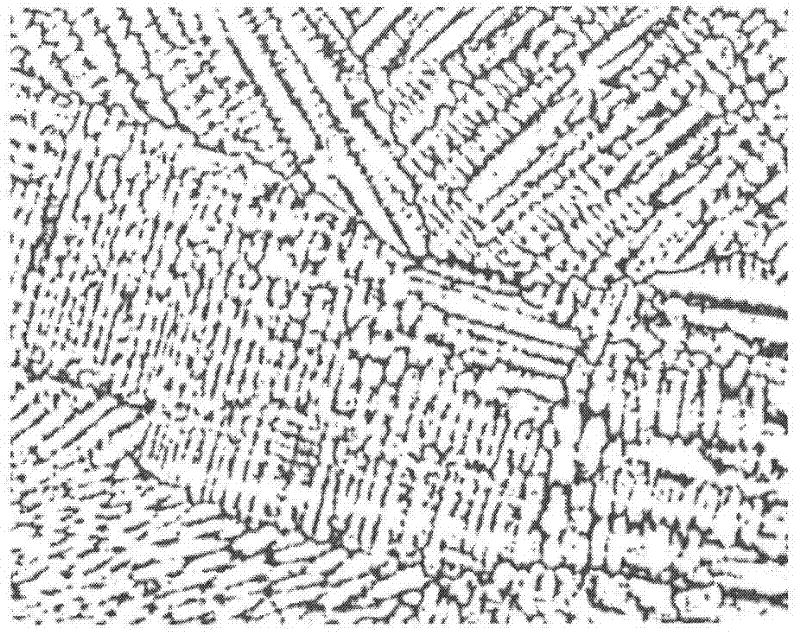

[0032] Cut a piece of sample with a size of 20mm×20mm on the battery grid alloy sample with a manual hacksaw. The specific implementation steps are as follows:

[0033] a. Wet grinding: the sample is first polished with a fine-toothed flat file, using flowing water as a coolant and lubricant, and then mechanically polished;

[0034] b. Mechanical polishing: put the wet-ground sample in water containing detergent, wash it in an ultrasonic vibration cleaner, and then perform mechanical polishing for about 2 minutes: the polishing speed is 500r / min; at this time, the polishing liquid is both a coolant and a Lubricant: Spray chromium oxide with a particle size of 0.5 μm on the microporous fabric polishing flannelette, mix it into water and stir the suspension evenly as a polishing liquid, polish the sample, observe the surface state of the sample under a microscope, and confirm that the surface of the sample is scratched by a file. Chemical polishing is carried out after the trac...

example 3

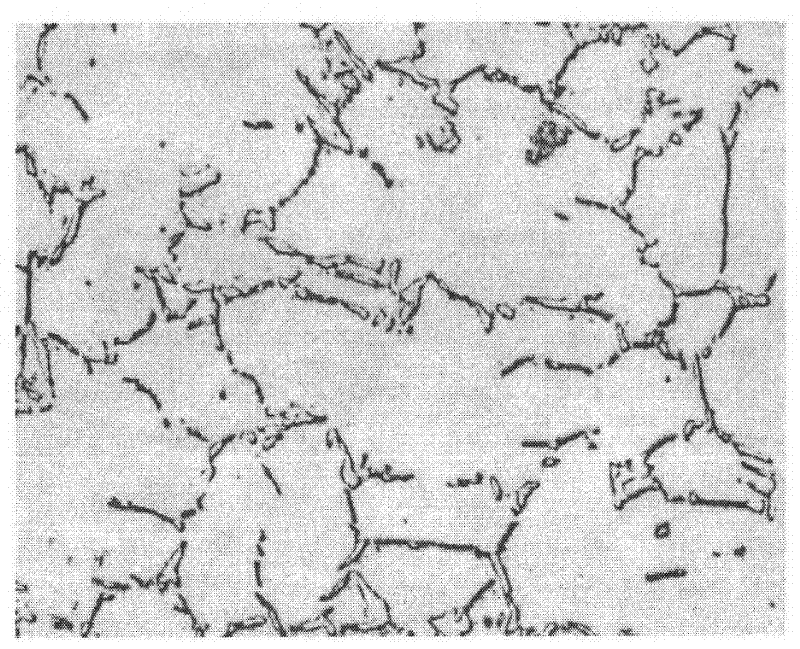

[0038] Cut a piece of sample with a size of 20mm×20mm on the battery grid alloy sample with a manual hacksaw. The specific implementation steps are as follows:

[0039] a. Wet grinding: the sample is first polished with a fine-toothed flat file, using flowing water as a coolant and lubricant, and then mechanically polished;

[0040] b. Mechanical polishing: put the wet ground sample in water containing detergent, wash it in an ultrasonic vibration cleaner, and then perform mechanical polishing for about 2 minutes: the polishing speed is 300r / min. At this time, the polishing liquid is both a coolant and a lubricant. agent; spray chromium oxide with a particle size of 0.5 μm on the microporous fabric polishing flannelette, transfer it into water and stir the suspension evenly as a polishing liquid, polish the sample, observe the surface state of the sample under a microscope, and confirm the file scratches on the surface of the sample Chemical polishing after complete disappear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com