Assembly for pouring paraffin into heat storage aluminum box, heat storage device and air conditioner

A paraffin and aluminum box technology, applied in the field of air conditioning, can solve the problems of affecting production efficiency, insufficient paraffin filling, and inability to guarantee the filling effect, etc., to achieve the effect of ensuring the filling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment describes in detail the assembly of the present invention for pouring paraffin into the thermal storage aluminum box.

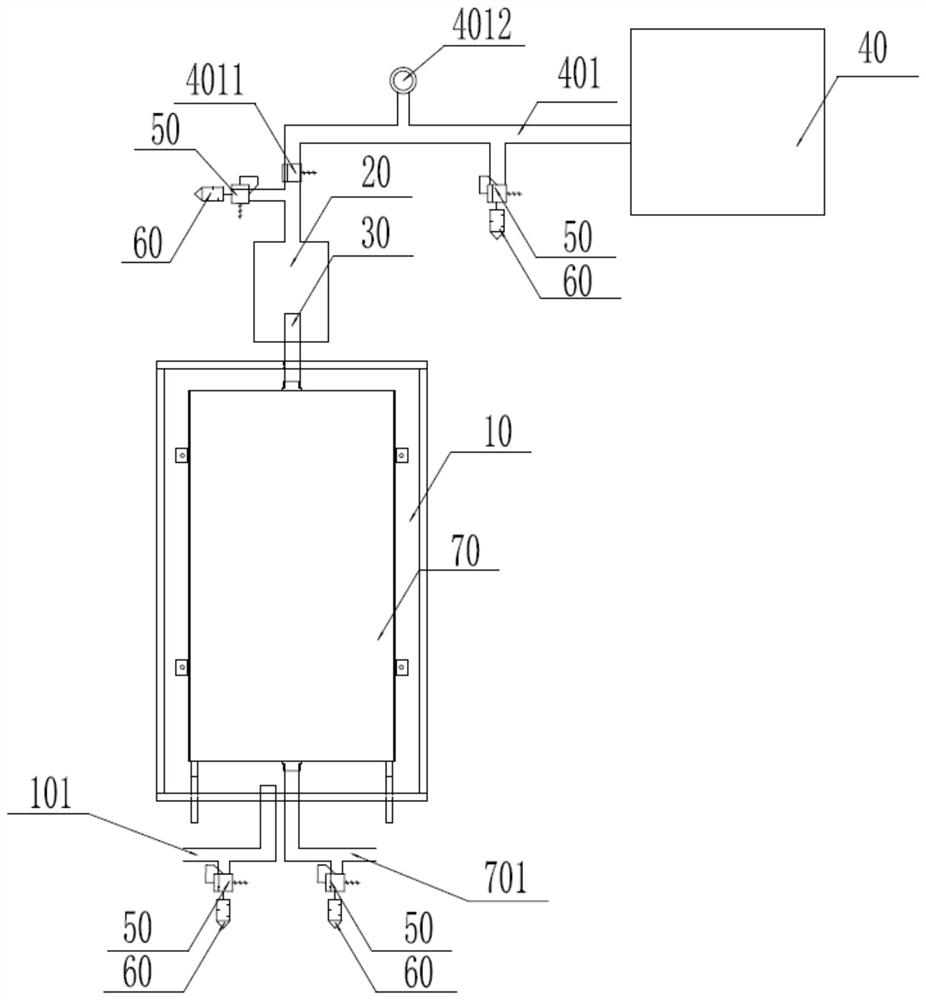

[0033] This embodiment is used to pour paraffin assembly to heat storage aluminum box, comprises sealed container 10 and paraffin injection assembly, as figure 1 shown. Preferably, the airtight container 10 is provided with a first air pipe 101, and the size of the airtight container 10 is larger than that of the heat storage aluminum box 70. When vacuuming, the heat storage aluminum box 70 is placed in the airtight container 10 and the airtight container 10 Sealing, the airtight container 10 and the heat storage aluminum box 70 are evacuated through the first air pipe 101 and the second air pipe 701 arranged on the heat storage aluminum box 70, and the vacuum degree difference between the airtight container 10 and the heat storage aluminum box 70 Less than the first preset difference; when the vacuum degree of the heat storage aluminu...

Embodiment 2

[0058] This embodiment describes the heat storage device of the present invention in detail.

[0059] The heat storage device of this embodiment includes a heat storage aluminum box 70 filled with paraffin wax, and the paraffin is filled by any technical solution in embodiment 1 for filling the heat storage aluminum box with paraffin wax. of. Preferably, the structures of the microchannel heat exchanger, flat tubes, and fins in the thermal storage aluminum box 70 of this embodiment are the same as those of the prior art, and will not be repeated here.

[0060] Compared with the traditional heat storage device, the paraffin filling amount of the heat storage device in this embodiment and the heat storage capacity of the heat storage device are effectively improved, which can not only ensure the paraffin filling effect and the heating effect during subsequent use, but also save manpower, material resources and Production time. That is, the heat storage device of this embodimen...

Embodiment 3

[0062] This embodiment describes the air conditioner of the present invention in detail.

[0063] The air conditioner in this embodiment includes an indoor unit and an outdoor unit, wherein the outdoor unit includes the heat storage device of any one of the technical solutions in Embodiment 2. Preferably, the remaining structures of the outdoor unit and the indoor unit of the air conditioner in this embodiment are the same as those of the prior art, and will not be repeated here.

[0064] The air conditioner in this embodiment includes an indoor unit and an outdoor unit, and the outdoor unit includes the heat storage device described in any one of the technical solutions in Embodiment 2. Since the filling amount of paraffin in the heat storage device is sufficient, it can ensure the defrosting of the outdoor unit in winter treatment, thereby ensuring the comfort of indoor air-conditioning users. That is, the air conditioner of this embodiment solves the technical problems in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com