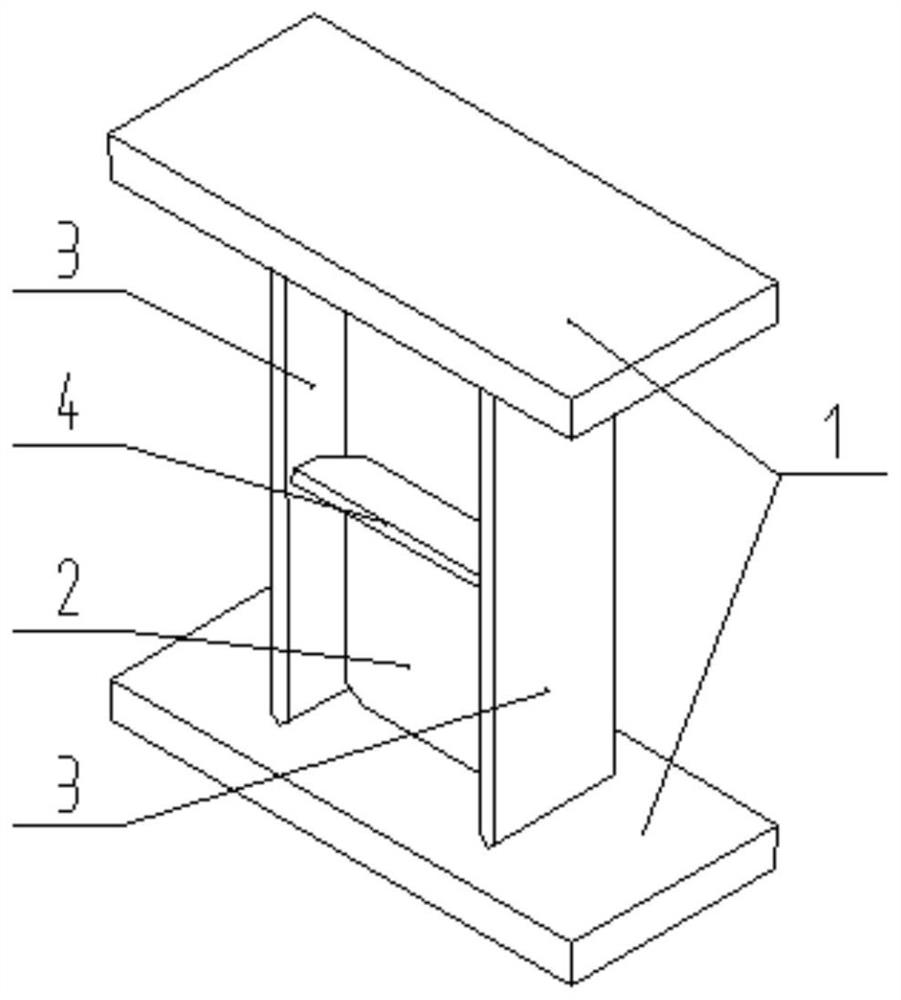

A Welding Process for Improving the Fatigue Performance of Metal Yield Dampers

A yield type damper, fatigue performance technology, applied in the direction of metal processing equipment, welding equipment, welding accessories, etc., can solve the problems of easy hardening structure, large grain size of structure, and the same quality of damper weld seam, etc., to improve Anti-fatigue performance, reducing stress concentration, and avoiding the effects of fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

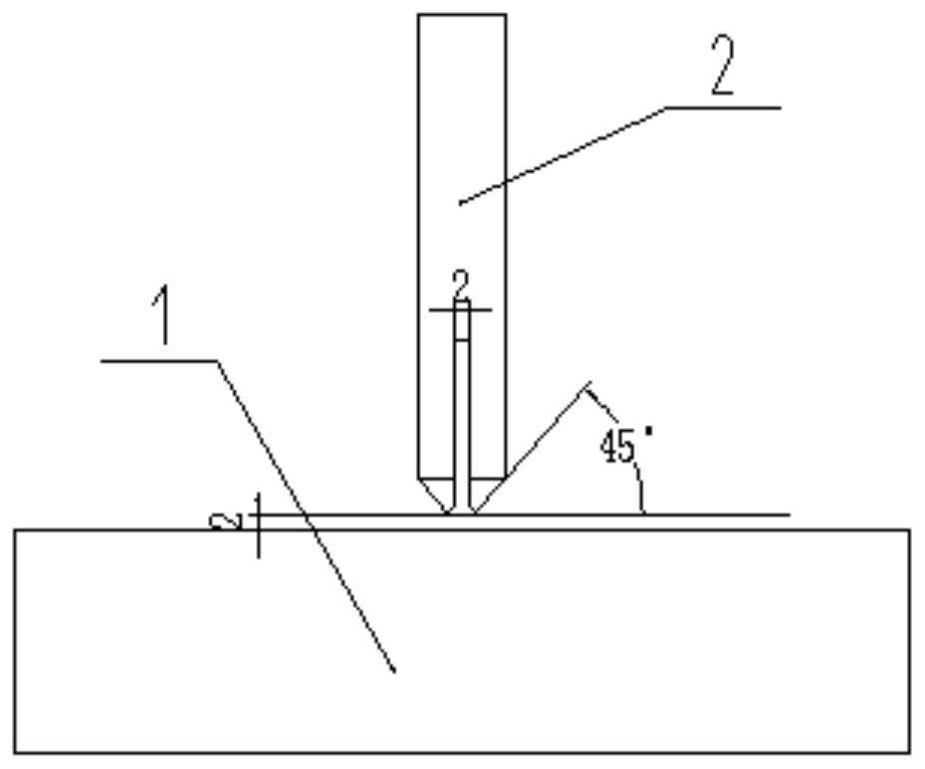

[0040] The difference from Example 1 is that in the step S2) of root welding, the process adopts pulse symmetrical welding, the wire feeding speed is 5 m / min, and the welding speed is 0.35 m / min.

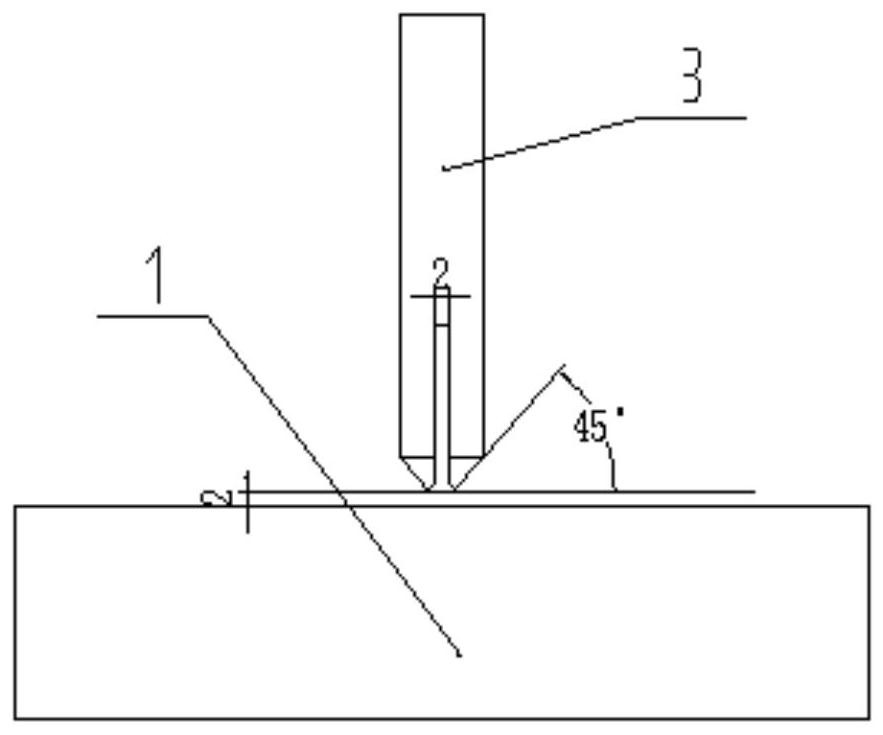

[0041]When the residence time at the end of the weld seam and the air supply time at the end of the weld seam are 0.8s, and the filling metal at the end of the weld seam is moderate, the problem of arc crater cracks can be solved and the welding strength can be improved. During bottom welding, gas shielded welding and pulse welding at the same time, after welding, due to the convection and heat dissipation of the surrounding air and the conduction and heat dissipation of the welded steel plate itself, the welding zone can produce a similar quenching effect and reduce the microstructure grains in the weld size, avoid hardened tissue. The invention ensures the penetration of the T-shaped weld seam of the metal yield damper by controlling the wire feeding speed, welding speed and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com