One-sided welding and double-sided forming welding method for titanium-steel composite pipe

A technology of single-sided welding and double-sided welding method, which is applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of complicated operation in the welding process, large welding stress deformation, and large cumulative heat input, etc., so as to facilitate the fusion transition , improve strength and toughness, and expand the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0040] A kind of embodiment of the present invention is: a kind of titanium-steel composite pipe (titanium alloy layer 3mm+steel metal layer 3-8mm, obtained by rolling method) single-sided welding double-sided forming welding method, comprising the following steps:

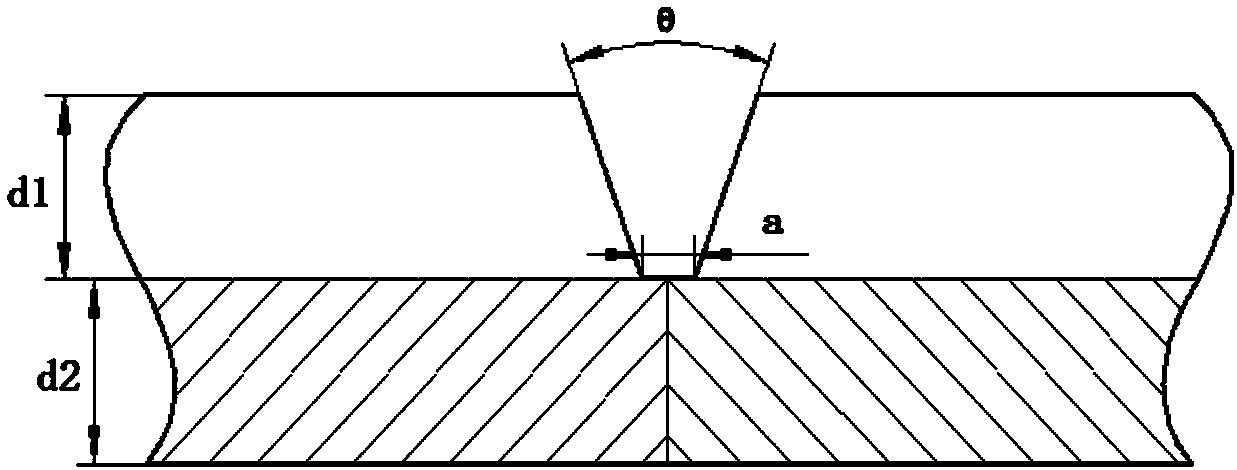

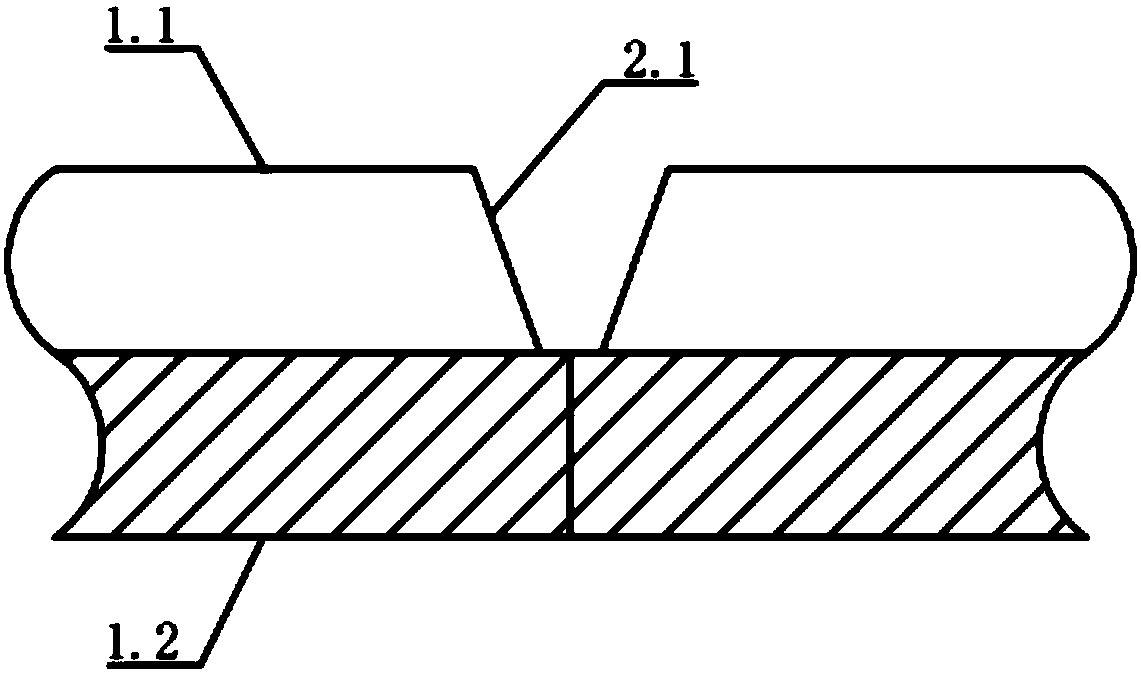

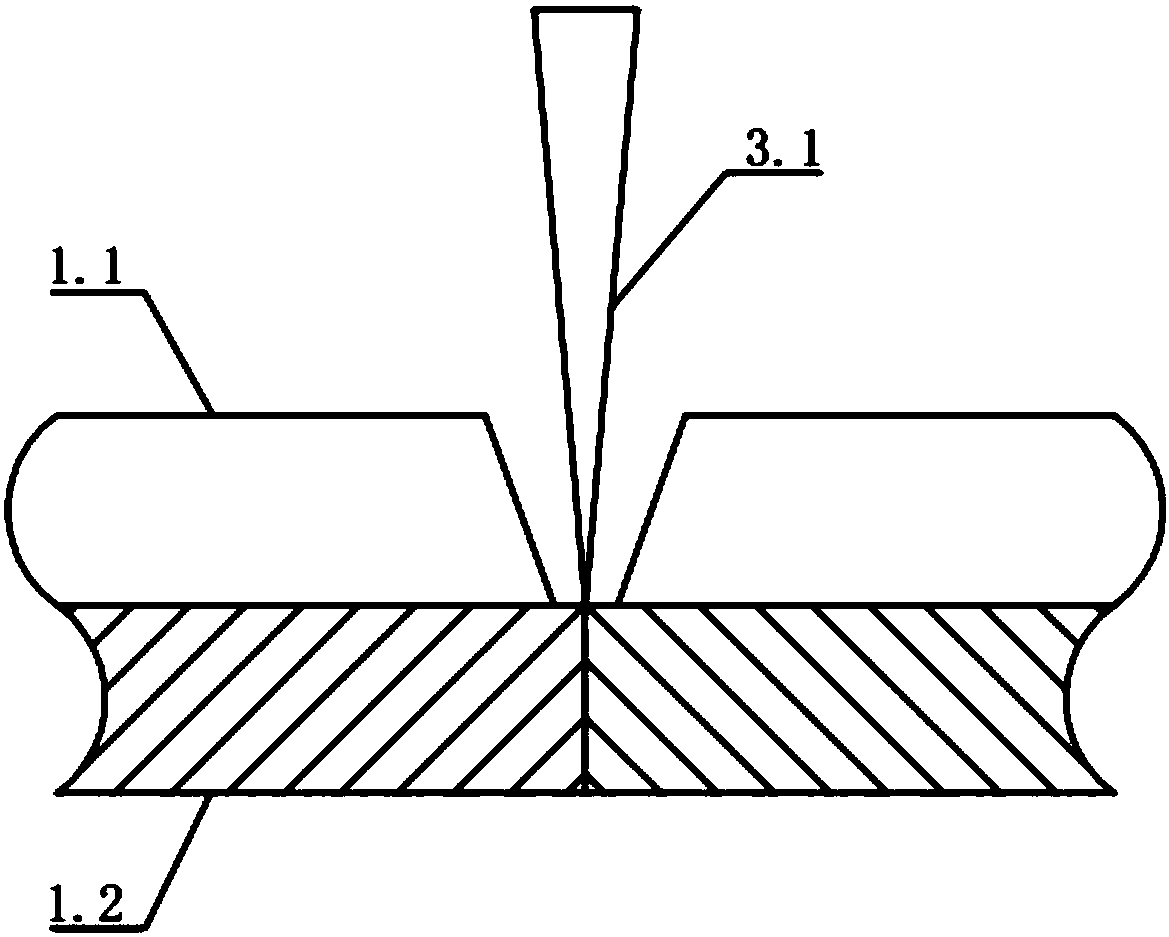

[0041] 1) Processing welding groove: processing a flat-bottomed trapezoidal groove with blunt edges on the pipe end of the titanium-steel composite pipe to be welded, the bottom edge of the flat-bottomed groove is close to the titanium alloy layer of the titanium-steel composite pipe to be welded, and the blunt edge The side size is the thickness of the titanium alloy layer; the groove angle is 15-20° on one side, and the bottom edge size of the groove is 1.4-2.4mm; figure 1 It is the design drawing of the welding groove in this example, figure 2 It is a schematic diagram of the titanium-steel composite pipe after the welding groove is processed in this example;

[0042] 2) Clean the welding area: clean the groo...

Embodiment 2

[0050] Another specific embodiment of the present invention is: a titanium-steel composite pipe (titanium alloy layer 3mm+steel metal layer 3-8mm, obtained by rolling) single-sided welding and double-sided forming welding method, comprising the following steps:

[0051] 1) Processing welding groove: processing a flat-bottomed groove with a blunt edge on the pipe end of the titanium-steel composite pipe to be welded, the bottom edge of the flat-bottomed groove is close to the titanium alloy layer of the titanium-steel composite pipe to be welded, and the blunt edge The size is the thickness of the titanium alloy layer; the groove angle is 15-20° on one side, and the size of the bottom edge of the groove is 1.4-2.4mm;

[0052] 2) Clean the welding area: clean the groove and the area to be welded of the titanium steel composite pipe to be welded. The cleaning area should not be less than 15mm from the edge of the groove, remove debris and oxide film, and then clean the area to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com