Patents

Literature

32results about How to "Achieve full penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

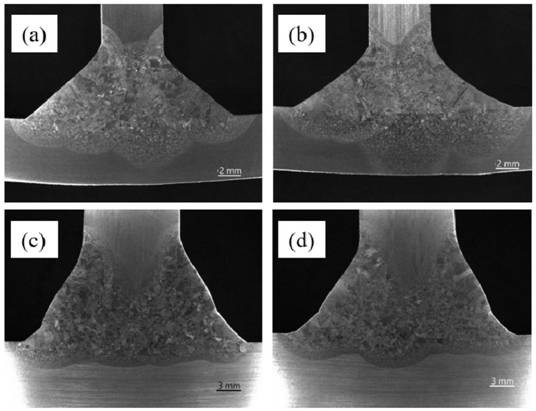

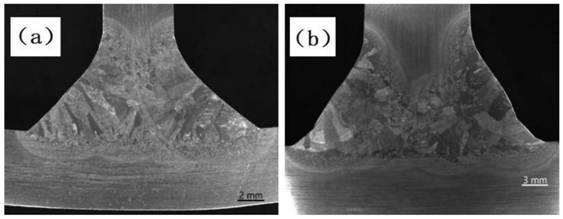

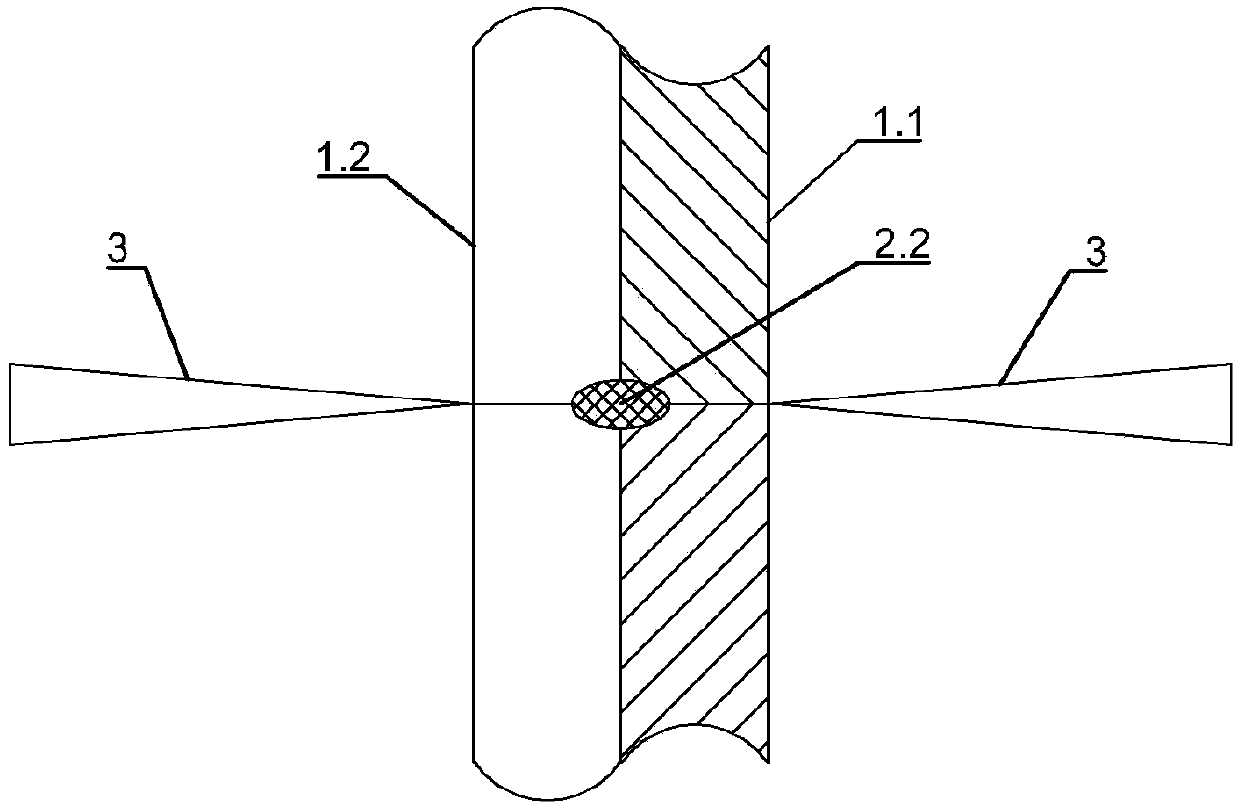

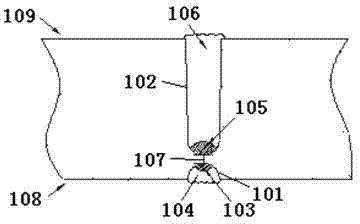

Double-sided laser titanium-steel clad plate full penetration welding method based on transition layer control

ActiveCN106425100ASimplified Soldering TechniquesImprove welding efficiency and qualityWelding/soldering/cutting articlesLaser beam welding apparatusTitaniumEngineering

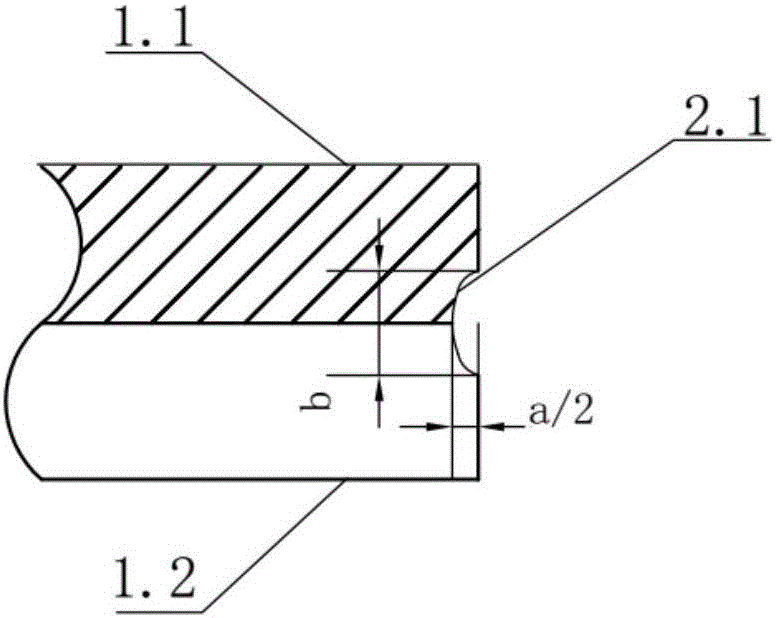

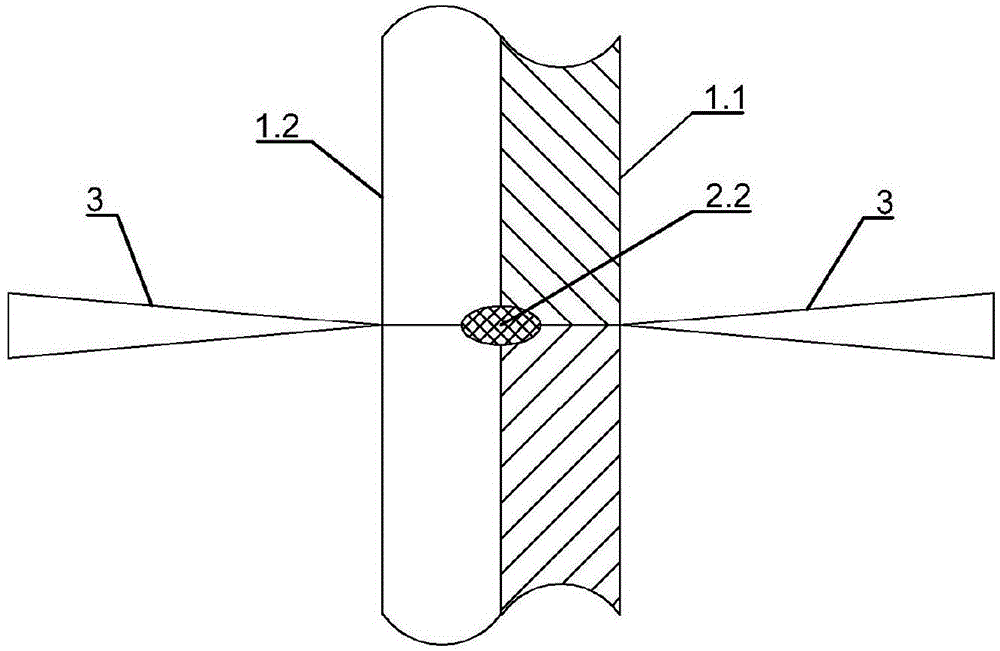

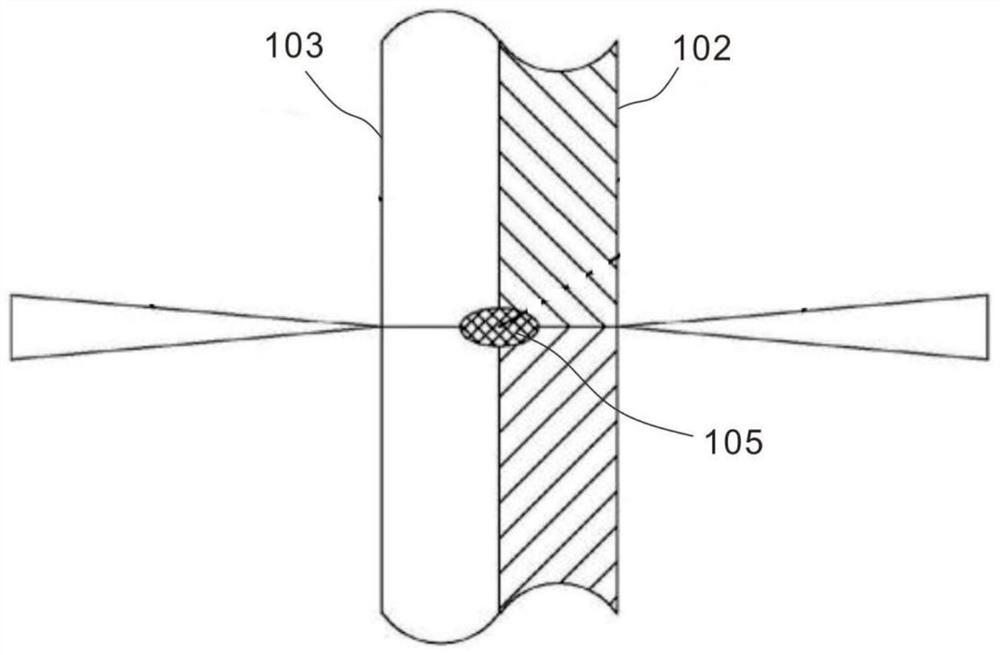

Provided is a double-sided laser titanium-steel clad plate full penetration welding method based on transition layer control. The method is suitable for welding of titanium-steel clad plates. The double-sided laser titanium-steel clad plate full penetration welding method based on transition layer control is provided in order to solve the problems that in the existing titanium-steel clad plate welding process, operation is complex, accumulated heat input is large, welding stress deformation is large, and the welding efficiency is low. The method comprises following steps that 1, semi-elliptical groove is prepared along a titanium-steel clad plate interface; 2, a welding area is cleaned; 3, a transition layer is prepared, wherein the transition layer is prepared by mixing a certain proportion of metal powder to be uniform; 4, laser welding is conducted on both sides, wherein after assembling and clamping are conducted, the titanium-steel clad plate is preheated to 100 DEG C to 120 DEG C, synchronous welding is conducted on the two sides with laser, and when welding is conducted, metal on the two sides is merged uniformly by controlling the linear energy. According to the double-sided laser titanium-steel clad plate full penetration welding method based on transition layer control, by means of control of the transition layer, the mechanical property of a welded joint of the titanium-steel clad plate is improved, an existing welding technology is simplified, and high-quality and high-efficiency welding is achieved.

Owner:SOUTHWEST JIAOTONG UNIV

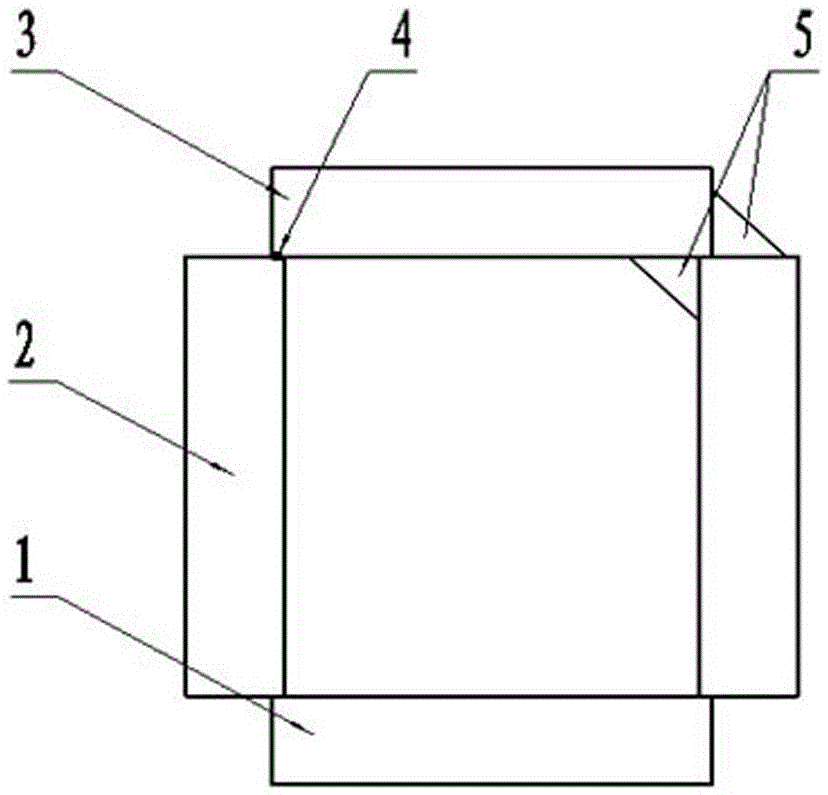

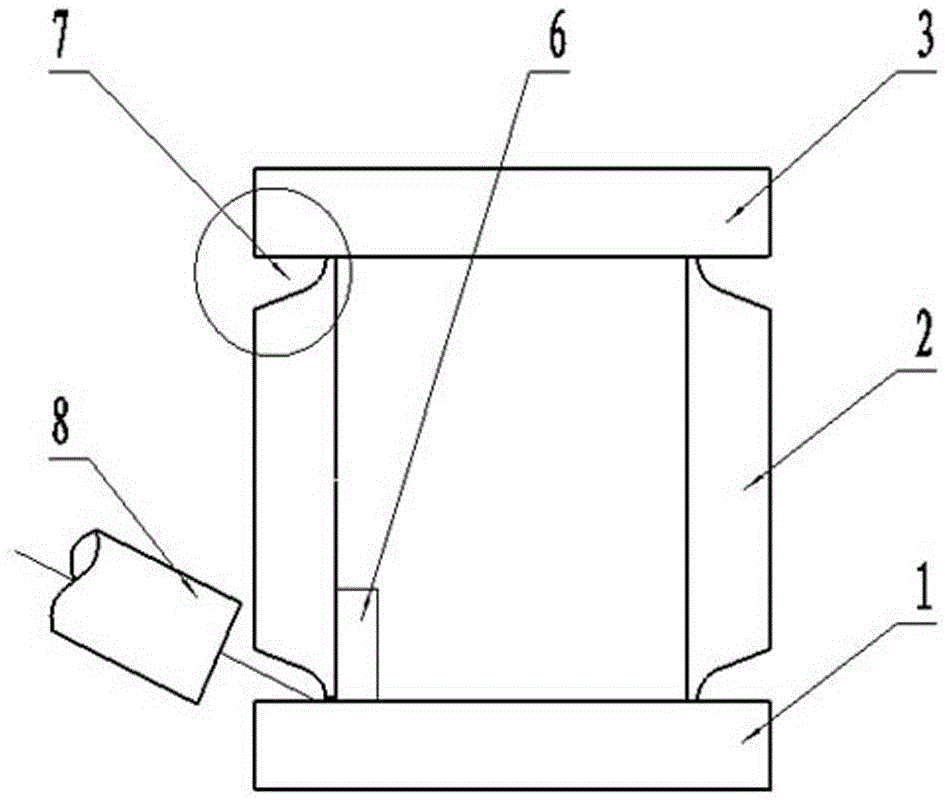

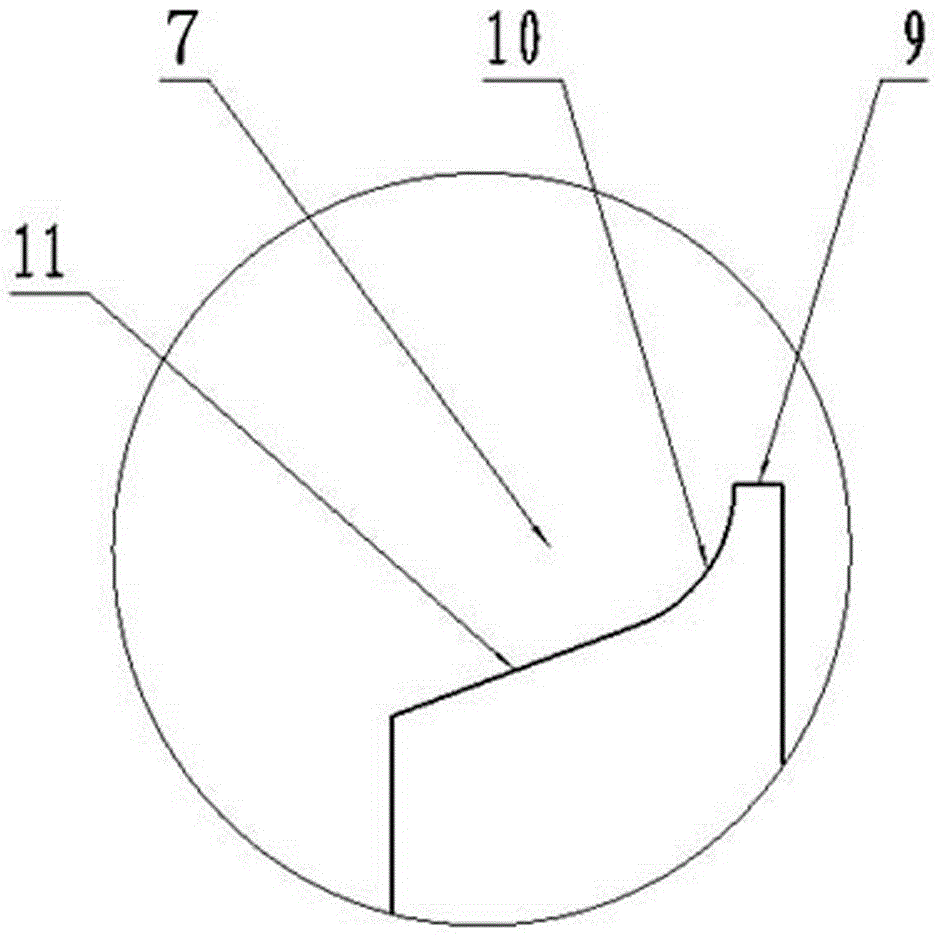

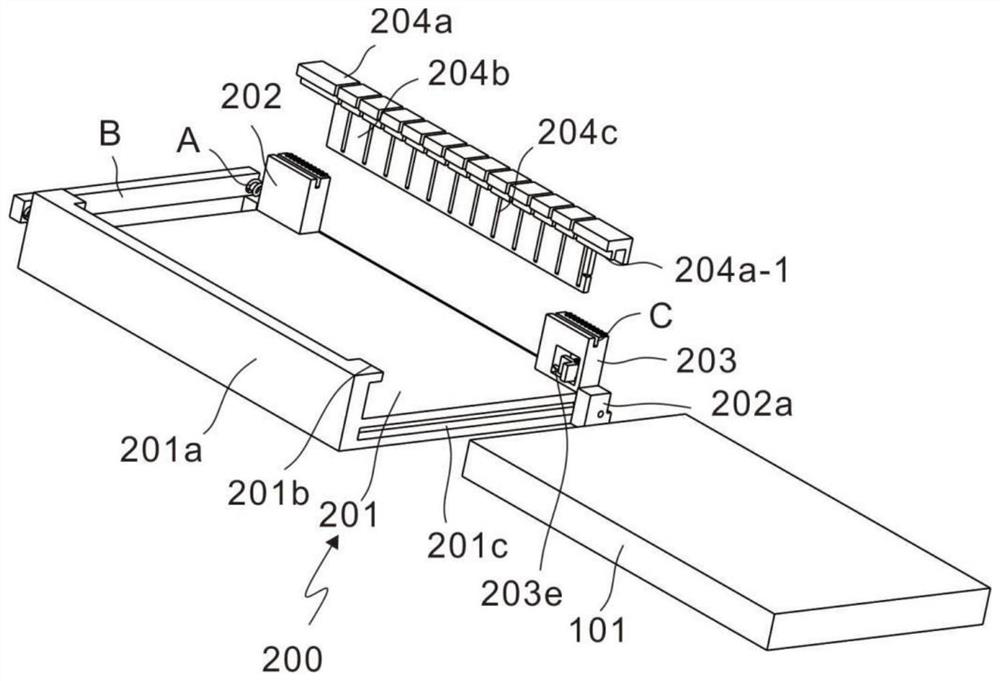

Full penetration weld method for fillet joint single-face J-shaped groove of box beam of vibration screen

ActiveCN104708172AEnsure consistencyStable controlArc welding apparatusMetal working apparatusMolten bathEngineering

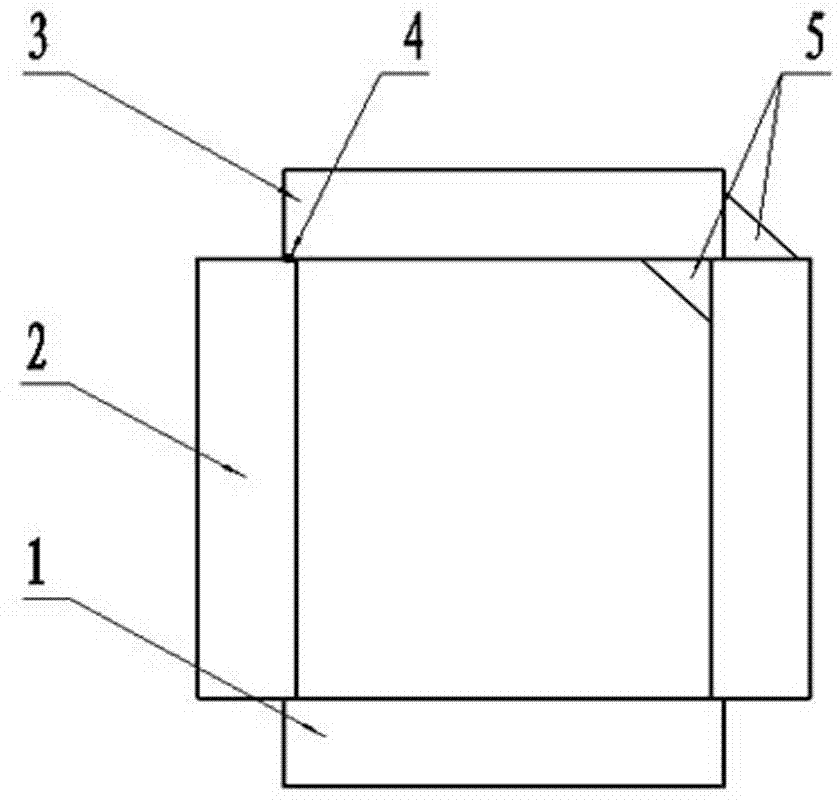

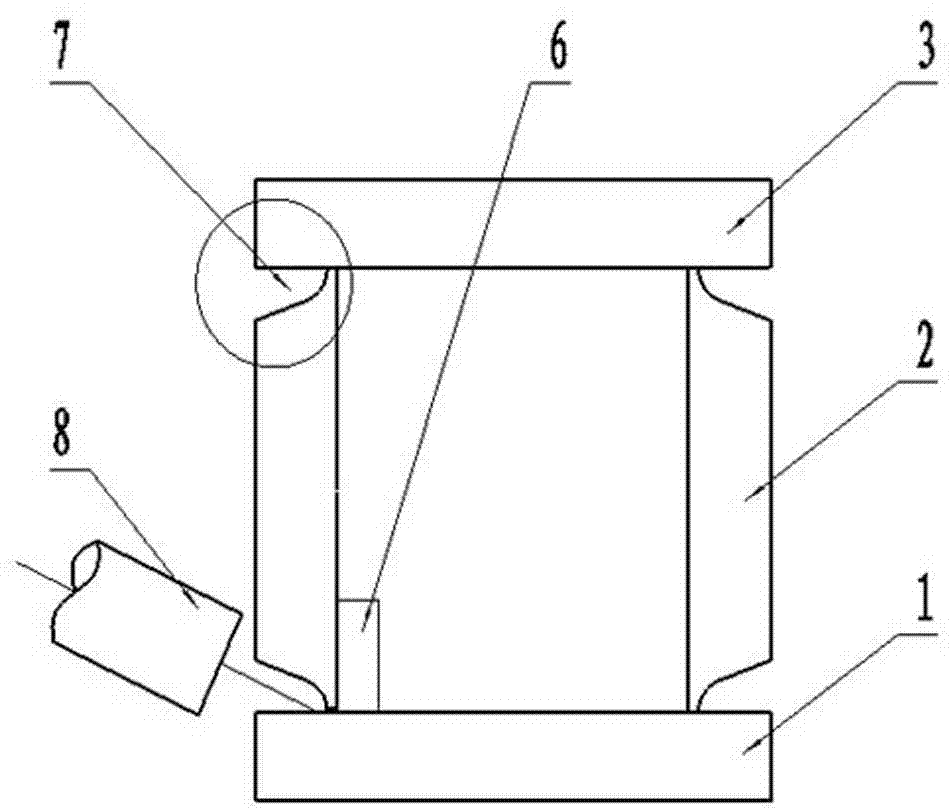

The invention provides a full penetration weld method for a fillet joint single-face J-shaped groove of a box beam of a vibration screen. According to the full penetration weld method, a weld back-up member is not additionally arranged, a general welding robot having a linear locating function is selected, weld joint molten bath forming influence factors and quantitative factor indexes formed by the technical features of a weld joint molten bath are effectively controlled, it is guaranteed that molten bath forming can be continuously and stably controlled in the welding process, and full penetration of the fillet joint single-face J-shaped groove of the type is achieved. By the adoption of the full penetration weld method, the problems in the welding process of similar fillet joint single-face J-shaped grooves of box beams of vibration screens, permanent backing-up members are not allowed to be used, different degrees of incomplete fusion and incomplete penetration are caused when detachable baking-up members are adopted, and full penetration of the weld joint cannot be guaranteed are solved, the welding technology process is simplified, the comprehensive production cost is greatly reduced, the efficiency is greatly improved by about two times, the labor intensity of welding operators is greatly relieved, and the welding quality of products is improved.

Owner:SHANXI PINGYANG IND MACHINERY

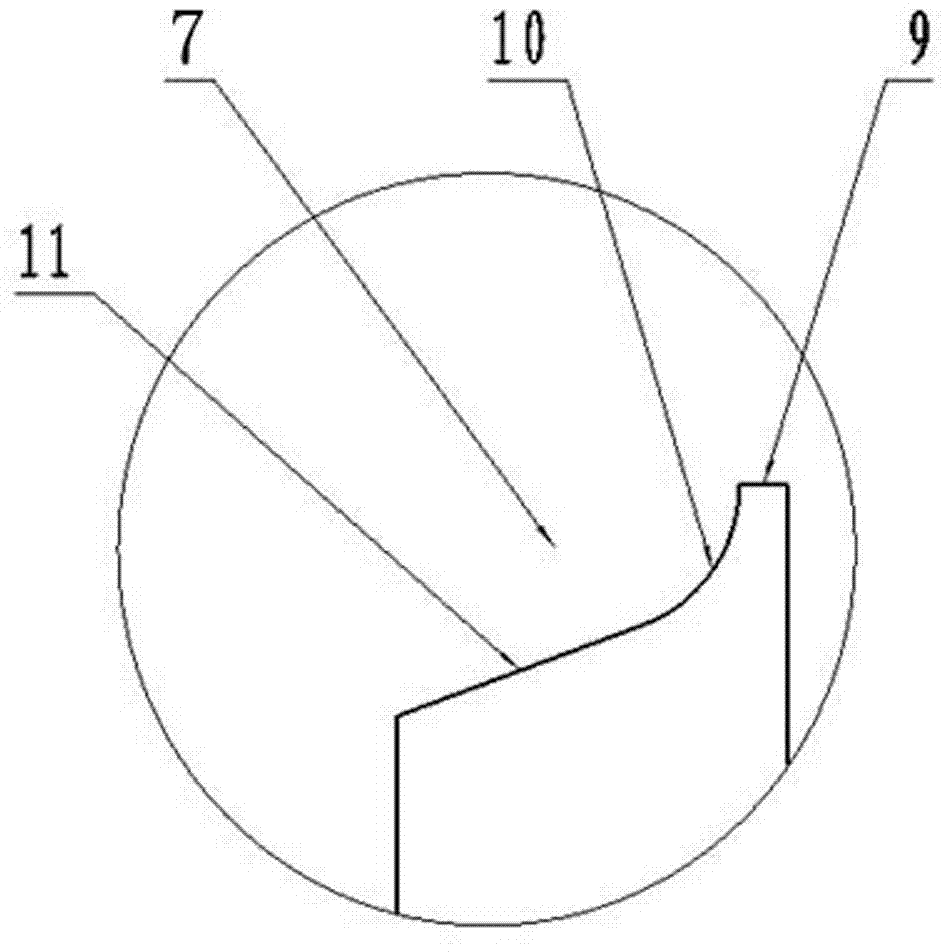

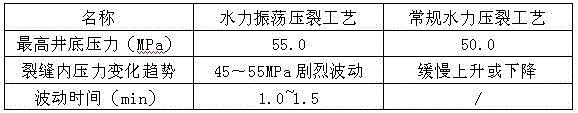

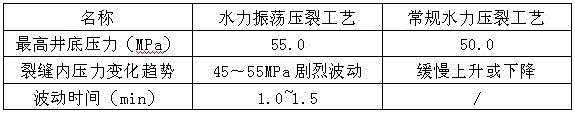

Hydraulic oscillation fracturing technology for oil and gas wells

ActiveCN103912255AAchieve full penetrationAchieve openFluid removalVibration devicesFracturing fluidPetroleum oil

The invention relates to the technical field of fracturing technologies implemented in petroleum extraction, and discloses a hydraulic oscillation fracturing technology for oil and gas wells. The hydraulic oscillation fracturing technology is characterized by at least comprising steps of 1), perforating fracturing modification target strata of the oil wells or the gas wells; 2), selectively utilizing compressible fluid as fracturing fluid and injecting the fracturing fluid in the target strata by the aid of phi88.9mm oil pipes with the displacement higher than 4.0m<3> / min; 3), injecting a certain quantity of fracturing fluid in a front fluid injection procedure after each stratum is fractured, then quickly stopping pumps, waiting for 30-60s after the pumps are stopped, repeatedly quickly stopping the pumps by 3-5 times in an integral front fluid injection stage, and sequentially increasing consumption of the fracturing fluid. The hydraulic oscillation fracturing technology has the advantages that the post-fracturing yields of the reservoir strata can be increased by the aid of the technology, a longitudinal complete penetration effect can be realized in longitudinal strong heterogenous reservoir stratum fracturing operation, and micro-fractures can be greatly opened in the micro-fracture developed reservoir strata.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

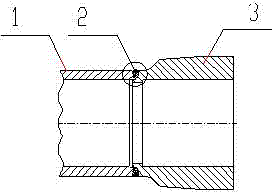

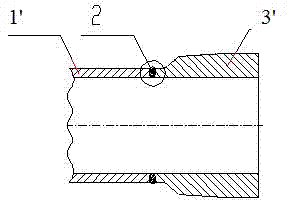

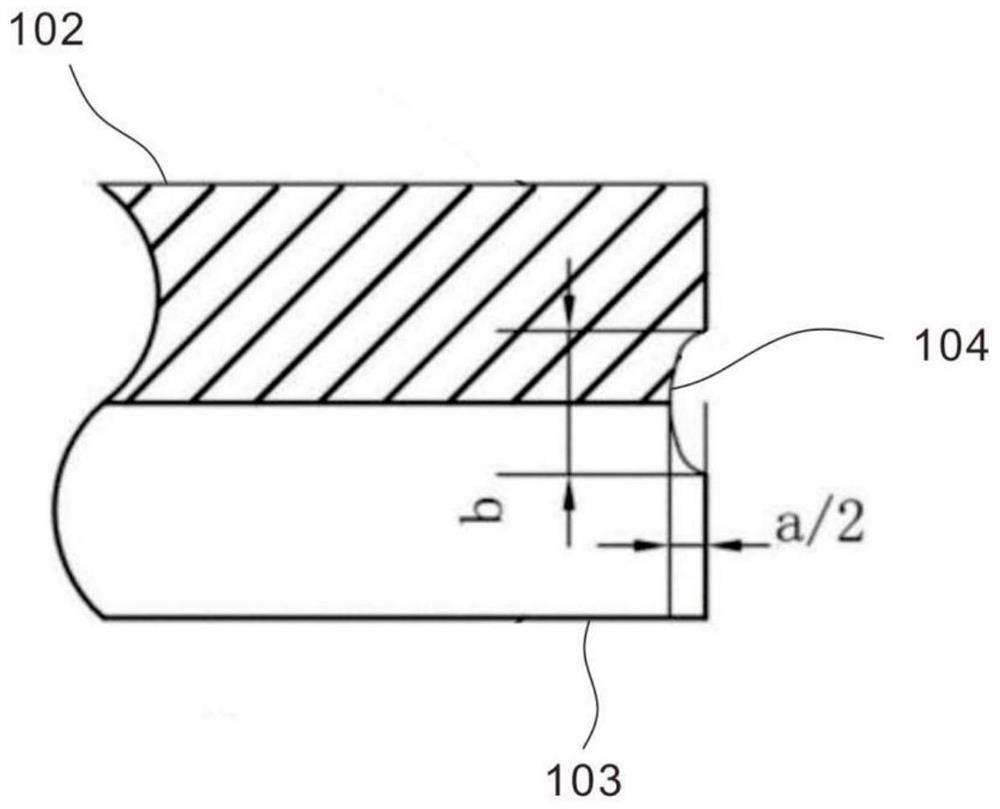

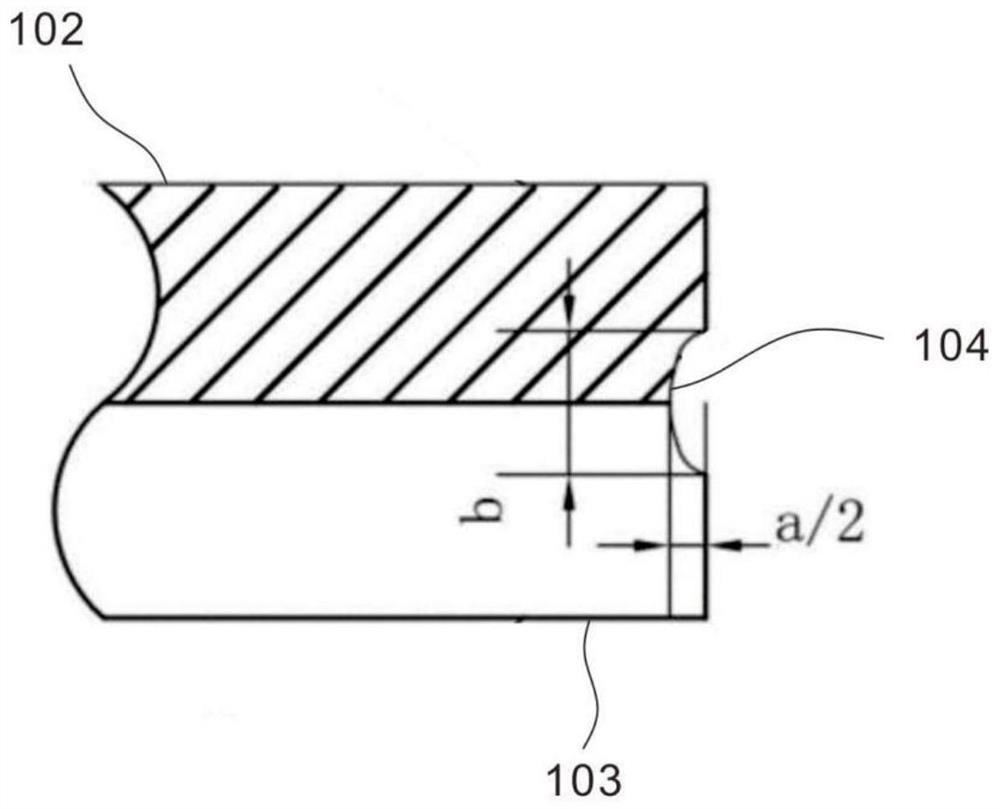

Welding structure of hydraulic cylinder jacket and processing technology thereof

InactiveCN104191096AReduce wall thicknessNot hurtWorkpiece edge portionsWelding apparatusHydraulic cylinderPulp and paper industry

The invention discloses a welding structure of a hydraulic cylinder jacket and a processing technology thereof, and belongs to the technical field of hydraulic cylinders. The welding structure of the hydraulic cylinder jacket comprises a cylinder body, and a jacket fixed at one end of the cylinder body, wherein an inner hole stop port is formed in one end of the cylinder body; a positioning cylinder is arranged at one end of the jacket; an outer circular stop port is formed in the outer side of the positioning cylinder; the positioning cylinder of the jacket is inserted in the inner hole stop port of the cylinder body; a loop of U-shaped welding line is arranged on a radial seam formed by two end surfaces of the cylinder body and the jacket; the complete fusion in welding can be guaranteed by the distance from the bottom end of the welding line to the outer surface of the positioning cylinder; and the cylinder body and the jacket can be fixedly welded in the welding line. As the fitting positioning mode of the hydraulic cylinder jacket and the cylinder body is changed, the wall thickness in a welding bead is reduced, the complete fusion in welding is realized, the purpose of obtaining a finished product having no abutting welding lines and welding defects is achieved, and a sealing piece performing the reciprocating movement is protected from being damaged.

Owner:XCMG HYDRAULICS CO LTD

Angle welding method of high penetration and low spatter

The invention relates to an angle welding method of high penetration and a high against gas hole. The angle welding method of the high penetration and the low-spatter has the characteristics that themethod adopts CO2 protection welding with a front-wire solid-core welding wire and a back-wire flux-cored wire, the current is 300-450 A and 280-400 A, the voltage is 25-30 V and 28-40 V, the weldingspeed ranges from 0.8 m to 1.4 m / min, the length of the welding wire is 10-15 and 20-30 mm, and Mn content of the solid-core welding wire is less than or equal to 1.0%, the content of Si+Mn of the solid-core welding wire is larger than or equal to 1.0% and less than or equal to 2.5%, the content of Ti is 0.02-0.2%, the content of S in the flux-cored wire is 0.005-0.02%, and the content of boron is0.005-0.05%. The method is suitable for fillet welding seam welding of a steel plate with primer, full penetration of 12-16 mm thick plates can be achieved.

Owner:张宇

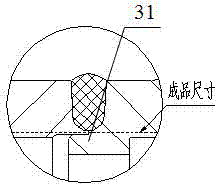

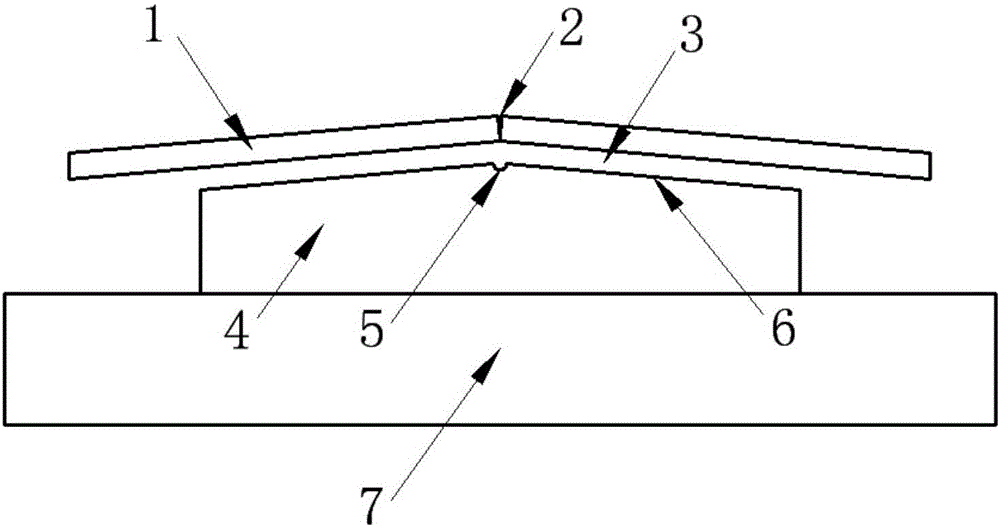

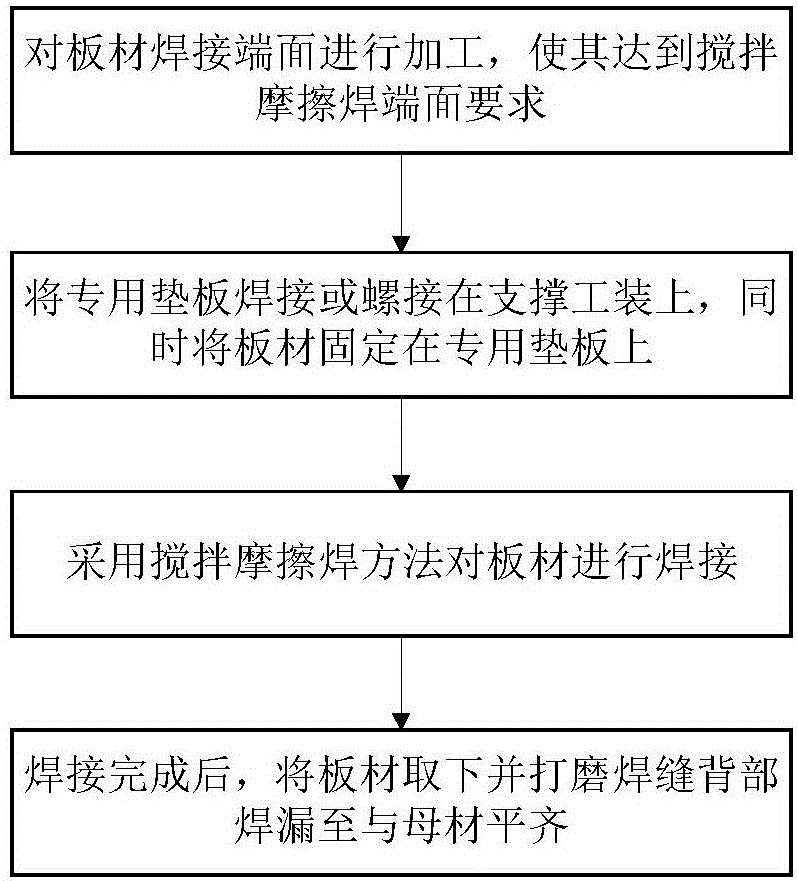

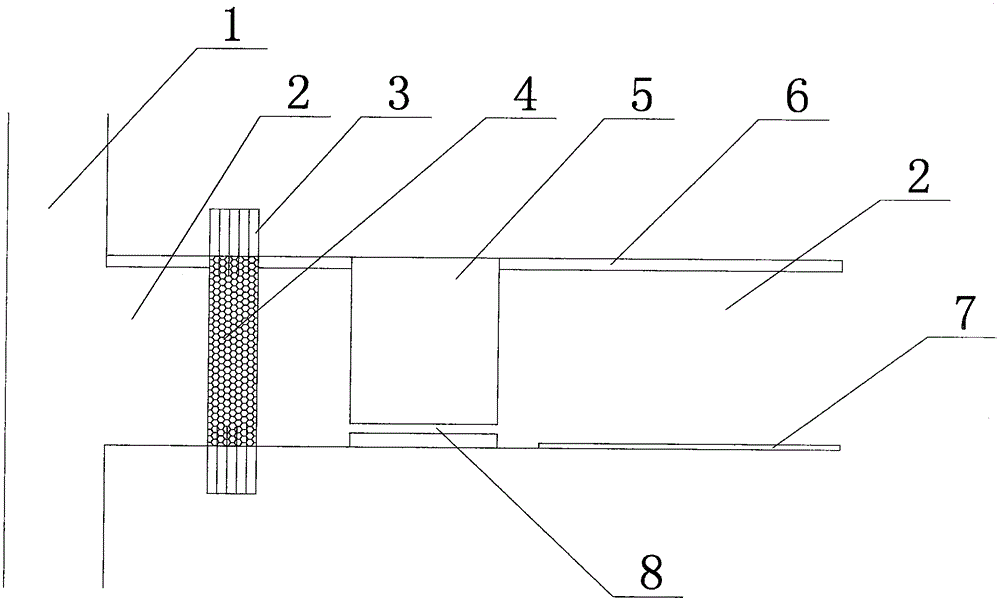

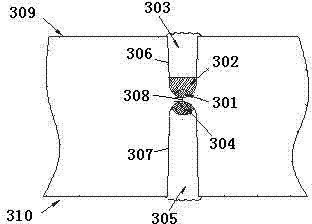

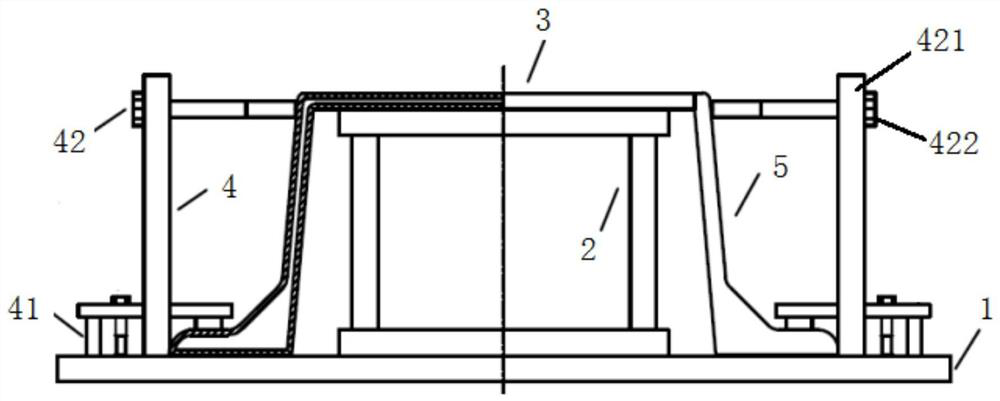

Special backing plate for friction-stir welding and welding method adopting backing plate

InactiveCN106513981AEasy to operateAdaptableWelding/soldering/cutting articlesNon-electric welding apparatusMechanical engineeringFriction stir welding

The invention provides a special backing plate for friction-stir welding and a welding method adopting the backing plate. A U-shaped or V-shaped welding leakage groove is formed in the center line of the special backing plate in the length direction. The welding leakage groove is located under a weld joint so that incomplete-penetration materials on the back of the weld joint can be squeezed into the welding leakage groove. The two sides of the welding leakage groove are bevels. The angles of the bevels are determined according to deformation of the plate. Through the special backing plate for friction-stir welding and the welding method adopting the backing plate, the incomplete-penetration materials on the back of the weld joint can be squeezed into the welding leakage groove; through the subsequent incomplete-penetration grinding procedure, the incomplete-penetration materials on the back of the weld joint are removed thoroughly, and complete penetration of the weld joint is realized. The two sides of the welding leakage groove are machined into the bevels used for conducting pre-welding predeformation on aluminum alloy plates so as to offset deformation generated in the welding process. Operation is easy. The adaptability is high.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

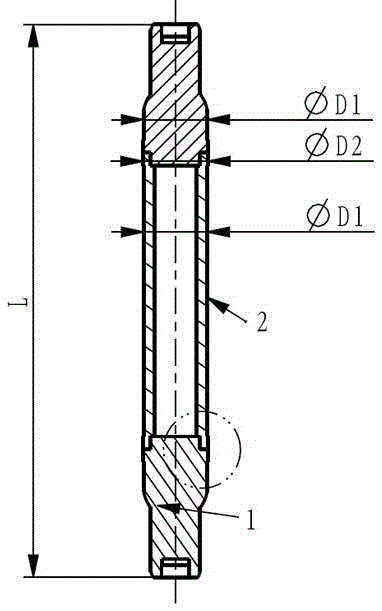

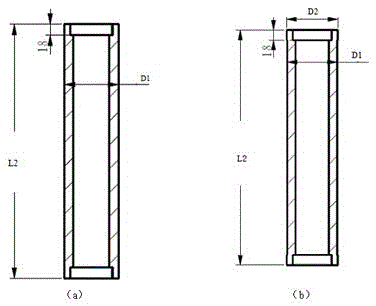

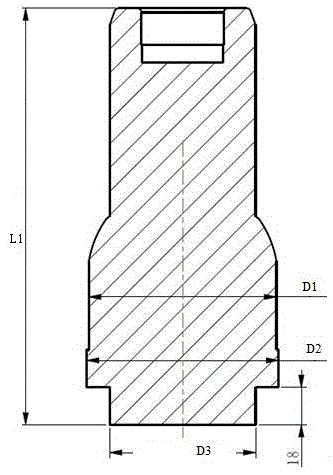

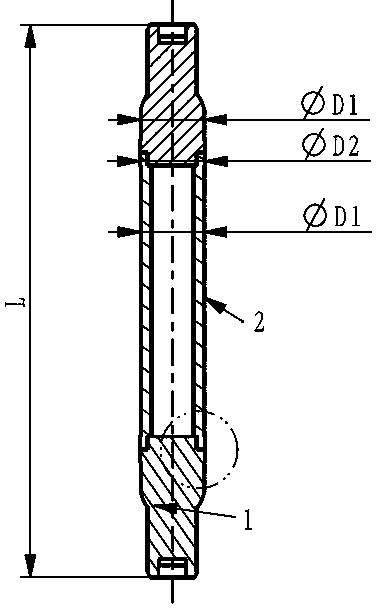

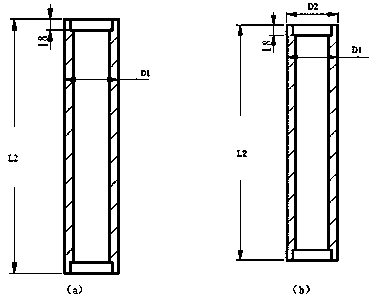

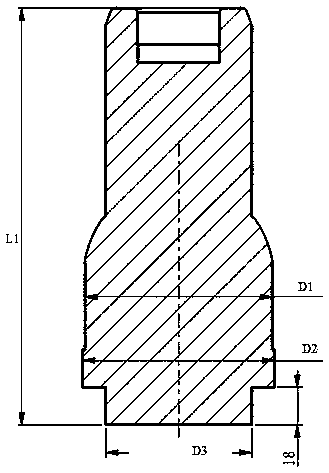

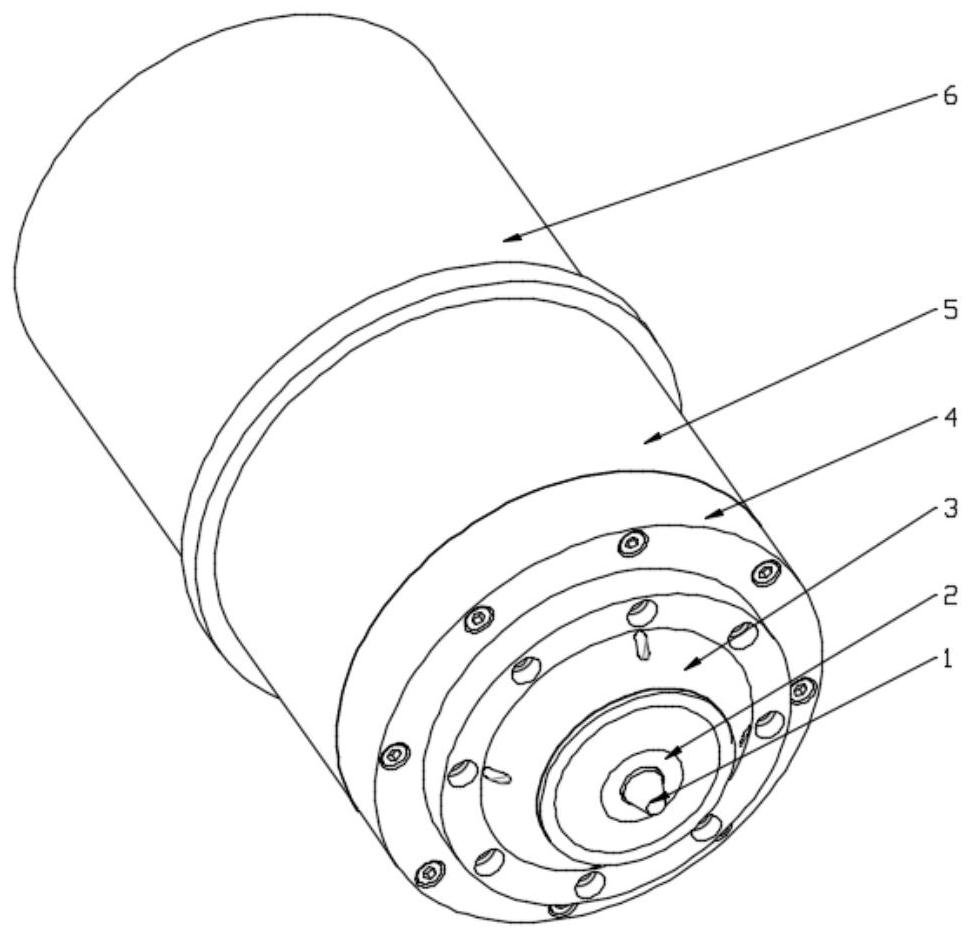

Aluminum alloy conductor pole manufacturing method

ActiveCN106825903ASolve quality problemsSolve the problem of longevityConductorsMetal working apparatusFriction weldingAutomatic control

The invention provides an aluminum alloy conductor pole manufacturing method. According to the method, a conducting body is manufactured firstly, specifically, extrusion forming, broaching forming and mechanical turning of a conducting rod are carried out; then a conducting head is manufactured, specifically, machining of the conducting head is mainly carried out; and finally, the conducting head and the conducting rod are connected through a no-keyhole stirring friction welding technology. By means of the aluminum alloy conductor pole manufacturing method, the problem of the welding quality of large-thickness small-diameter circular seams is solved, and the method has remarkable advantages compared with the prior art. By adoption of the conductor pole manufacturing method, the joint assembly design of the conducting rod and the conducting head as well as the no-keyhole stirring friction welding technology, the qualified rate of manufacturing of conductor poles is greatly improved, the production efficiency is improved, and the production cost is reduced. Tests prove that by adoption of the aluminum alloy conductor pole manufacturing method, the manufacturing dimension precision of the conductor poles meets the design requirement, weld joints are continuous and compact in texture, the defects including pores, impurities and keyholes are avoided, and automatic control is achieved in the production process; and the yield of one-time welding is increased from 40% to 95%.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

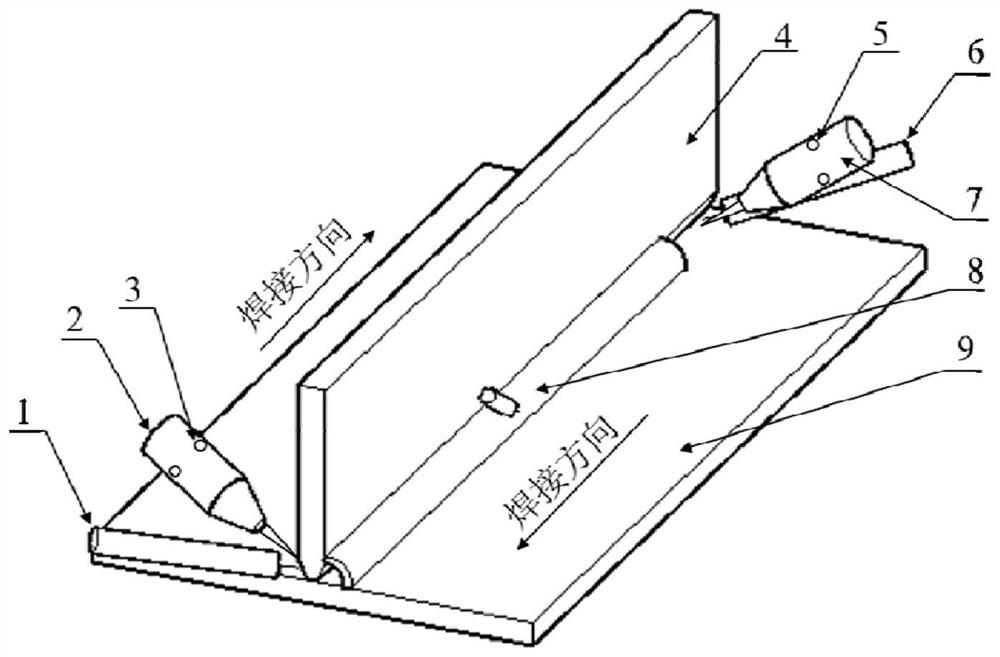

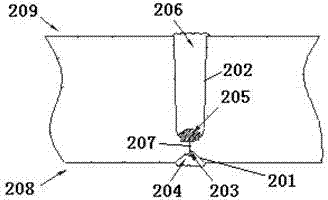

Welding method for heterogeneous titanium alloy T-shaped joint

ActiveCN113814535AImprove consistencyImprove welding strengthArc welding apparatusIncreasing energy efficiencyShielding gasStructural engineering

The invention discloses a welding method of a heterogeneous titanium alloy T-shaped joint, which comprises the following steps of: 1, processing a to-be-welded part of a rib plate into a K-shaped groove, and fixing the K-shaped groove on a welding tool clamp; 2, adopting coaxial powder feeding type laser cladding, wherein lasers act on the to-be-welded area on the two sides of the T-shaped connector correspondingly, an MIG welding gun swinging periodically is arranged on the rear side of a laser beam, and the included angle between the MIG welding gun and the rib plate and the included angle between the laser beam and the rib plate are adjusted to be located on the same plane; 3, setting welding process parameters; and 4, introducing shielding gas in advance, conducting double-face laser cladding composite electric arc welding of the T-shaped connector, conducting synchronous different-direction welding on welding heat sources on the two sides, wherein electric arcs swing periodically, single-pass welding forming of the workpiece is achieved, and the shielding gas is continuously introduced for cooling after welding. The laser cladding powder is used for regulating and controlling configuration, the internal consistency of the welding seam is enhanced, the welding seam strength is improved, and cracks are restrained through components of the welding wire before solidification of a molten pool.

Owner:JIANGSU UNIV OF SCI & TECH +1

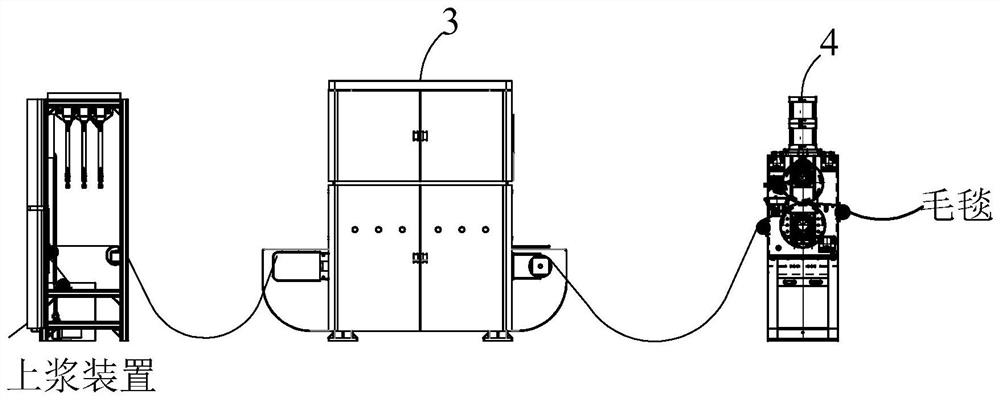

Raschel blanket digital ink-jet printing method

ActiveCN113062134AUnlimited patternImprove efficiencyDyeing processTextile treatment by spraying/projectingTextile printerProcess engineering

The invention relates to a Raschel blanket digital ink-jet printing method. The method comprises the following steps of 1, performing sizing: feeding a Raschel blanket subjected to pre-finishing treatment into a sizing device, carrying out pre-wetting treatment before sizing, and spraying white paste to the Raschel blanket by the sizing device, wherein the sizing device adopts a spraying sizing device capable of preventing blanket fluff from being pressed down, the white paste is composed of a synthetic thickener, water and a penetrant, and the viscosity of the white paste is 500-3000 CPS; 2, feeding the sized Raschel blanket into a digital ink-jet printing machine for ink-jet printing, wherein the printing procedure of the digital ink-jet printing machine comprises the steps that a designed pattern is called into printing software, the use amounts of all basic ink are automatically matched through an intelligent color matching and ink amount calculation method in the printing software, and the sized Raschel blanket is printed; and 3, feeding the Raschel blanket subjected to ink-jet printing into a pressure infiltration machine for pressure infiltration treatment.

Owner:HANGZHOU HONGYING DIGITAL TECH CO LTD

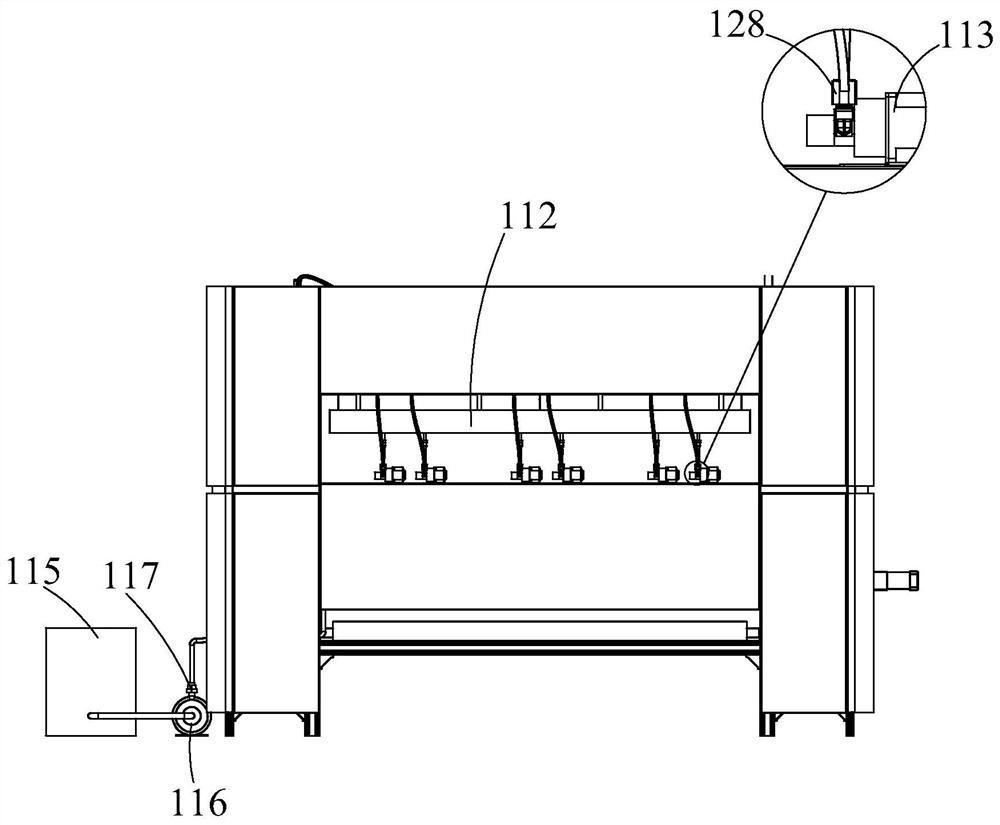

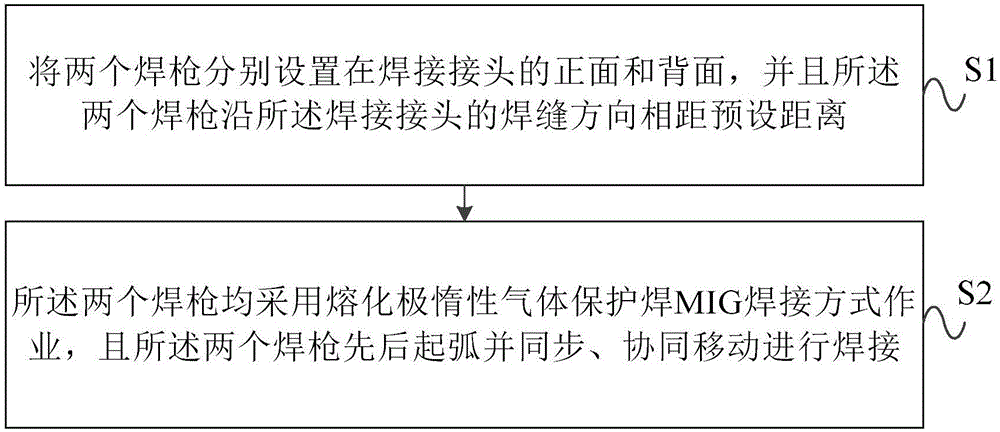

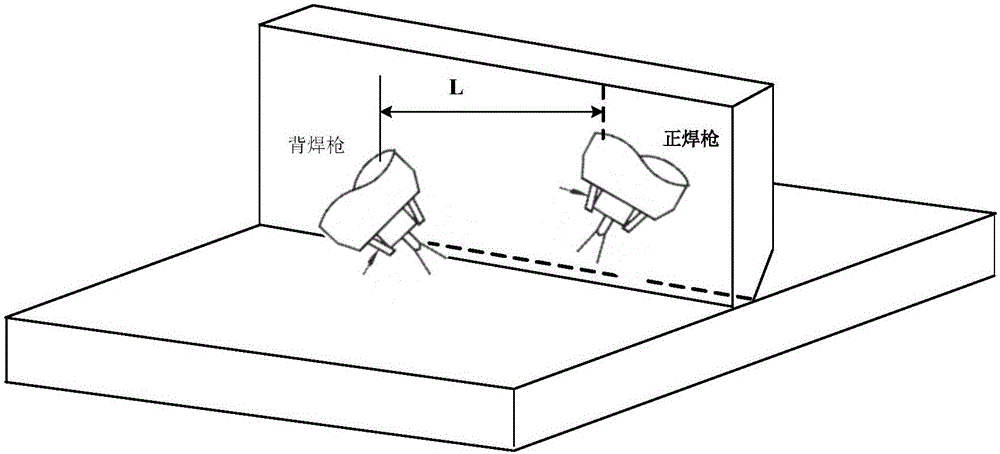

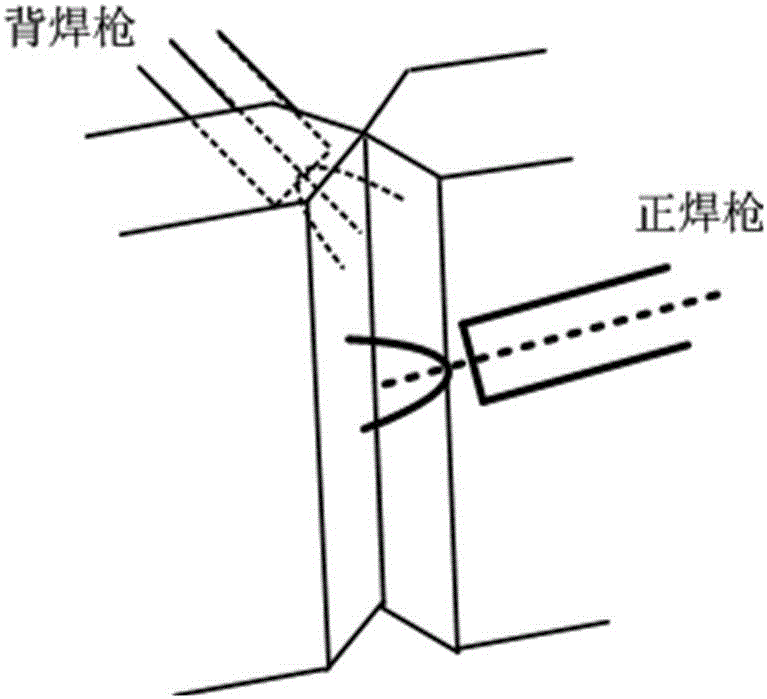

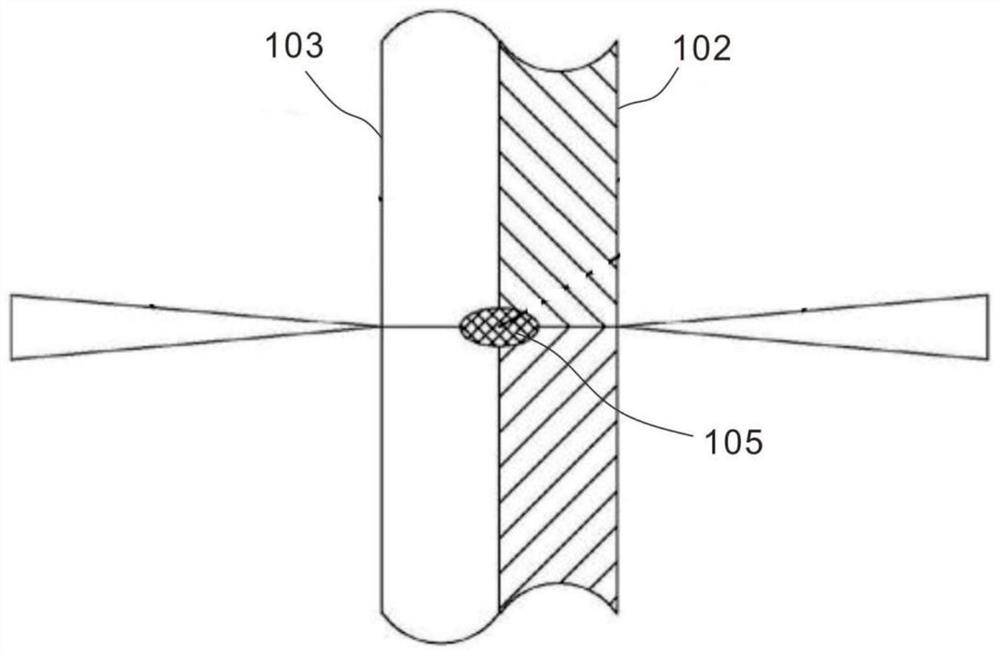

Aluminum and aluminum alloy double-gun double-face collaborative welding method

InactiveCN107520528AReduce heatExtended service lifeArc welding apparatusWelding/soldering/cutting articlesMaterials scienceMetal

The embodiment of the invention provides an aluminum and aluminum alloy double-gun double-face collaborative welding method. The aluminum and aluminum alloy double-gun double-face collaborative welding method comprises the steps that two welding guns are arranged on the front face and the back face of a welding joint correspondingly with a preset distance in the weld direction of the welding joint; and the two welding guns both operate in a metal inert-gas (MIG) welding mode, strike arcs successively and move synchronously and collaboratively to conduct welding. According to the aluminum and aluminum alloy double-gun double-face collaborative welding method, full penetration of a root of aluminum and aluminum alloy under the zero clearance condition is achieved, the welding joint with the large thickness can be welded through MIG welding, the quality of the welding joint of the aluminum and aluminum alloy is improved, and the service life of a weldment is prolonged.

Owner:CRRC QINGDAO SIFANG CO LTD

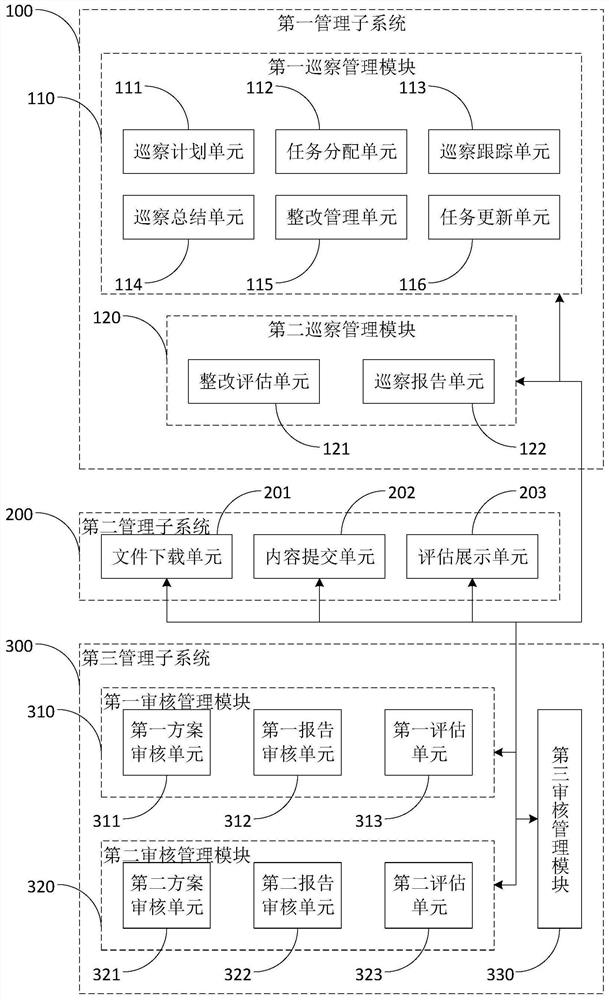

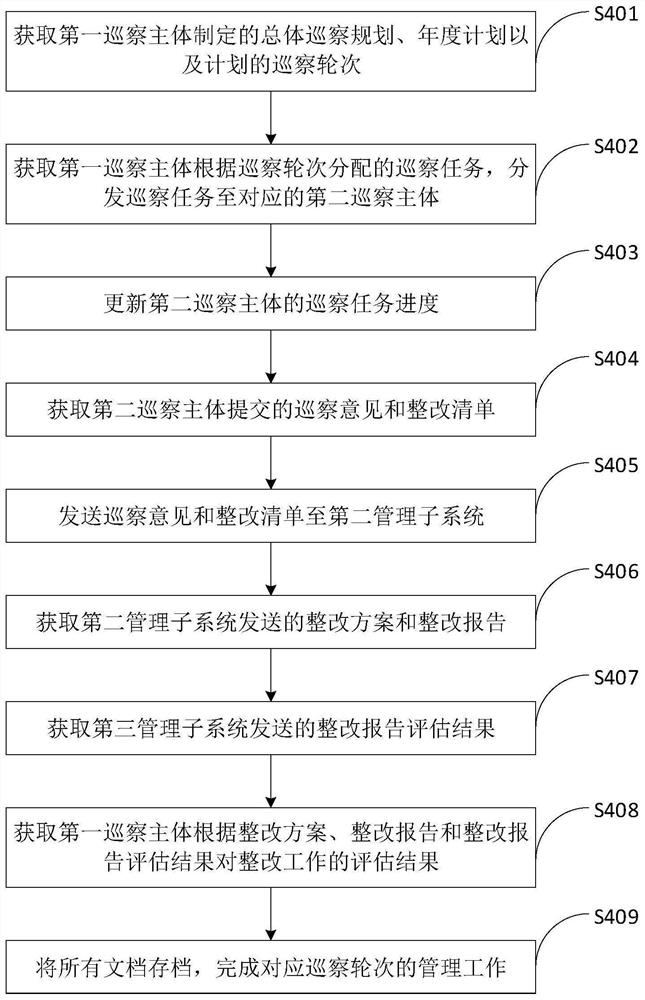

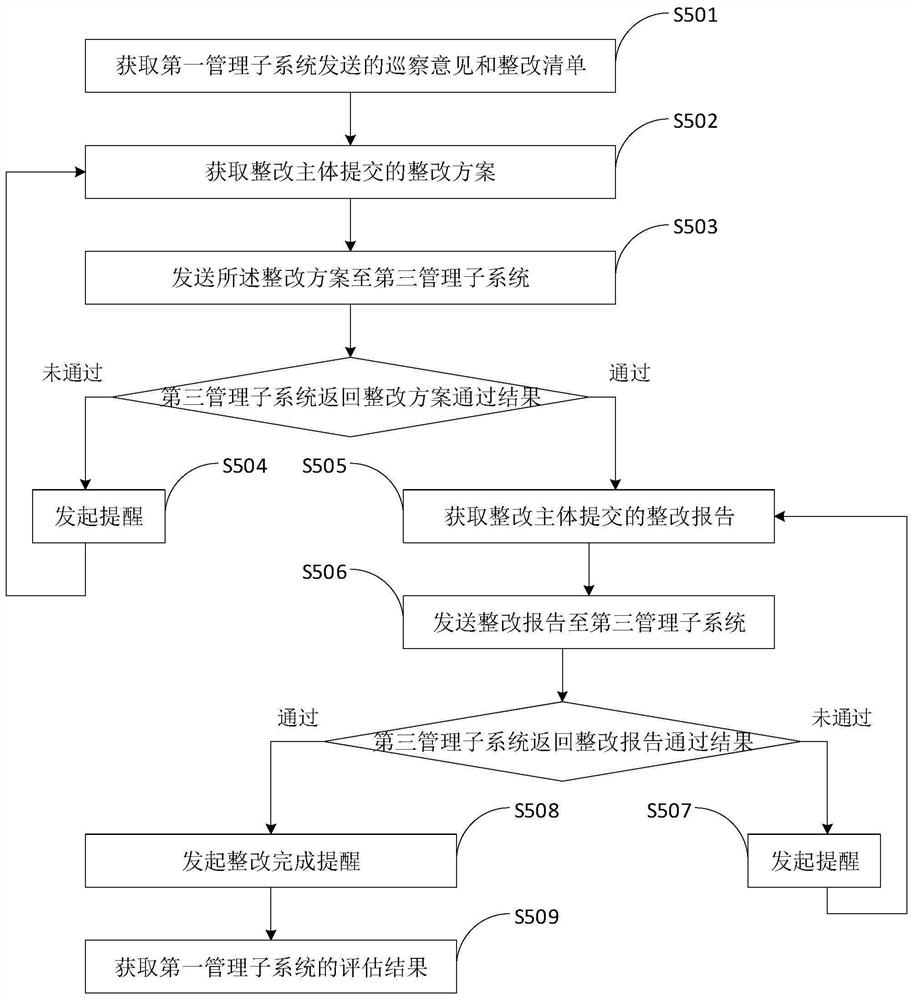

Rectification work management system and method

The invention is suitable for the technical field of informatization work management, and provides a rectification work management system and method, and the system comprises: a first management subsystem which is used for the inspection and rectification work management of an inspection main body; the second management subsystem that is used for carrying out rectification work management by the rectification main body according to the inspection rectification opinions issued by the inspection main body; and the third management subsystem that is used for managing the rectification audit workof the audit subject. According to the embodiment of the invention, all work before patrol, during patrol and after patrol is effectively linked, full penetration and full coverage of rectification management are realized, and closed-loop management of a patrol preparation stage, a development stage, a rectification stage and an auditing evaluation stage is achieved.

Owner:聚通智用(重庆)信息科技有限公司

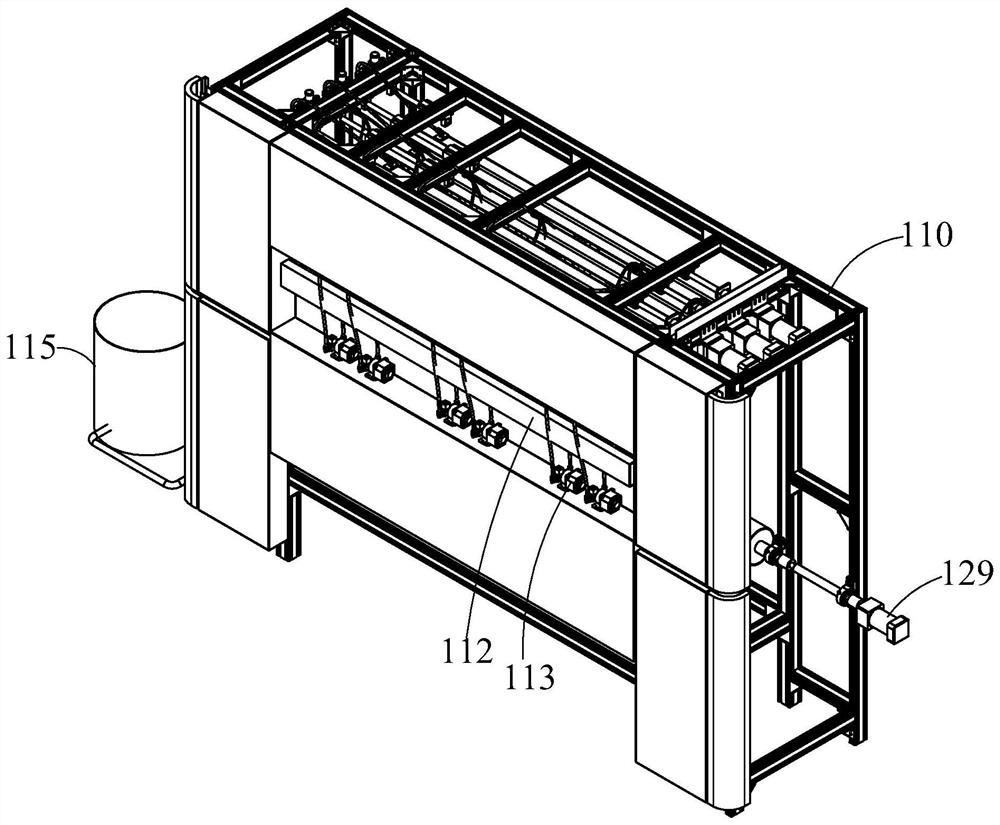

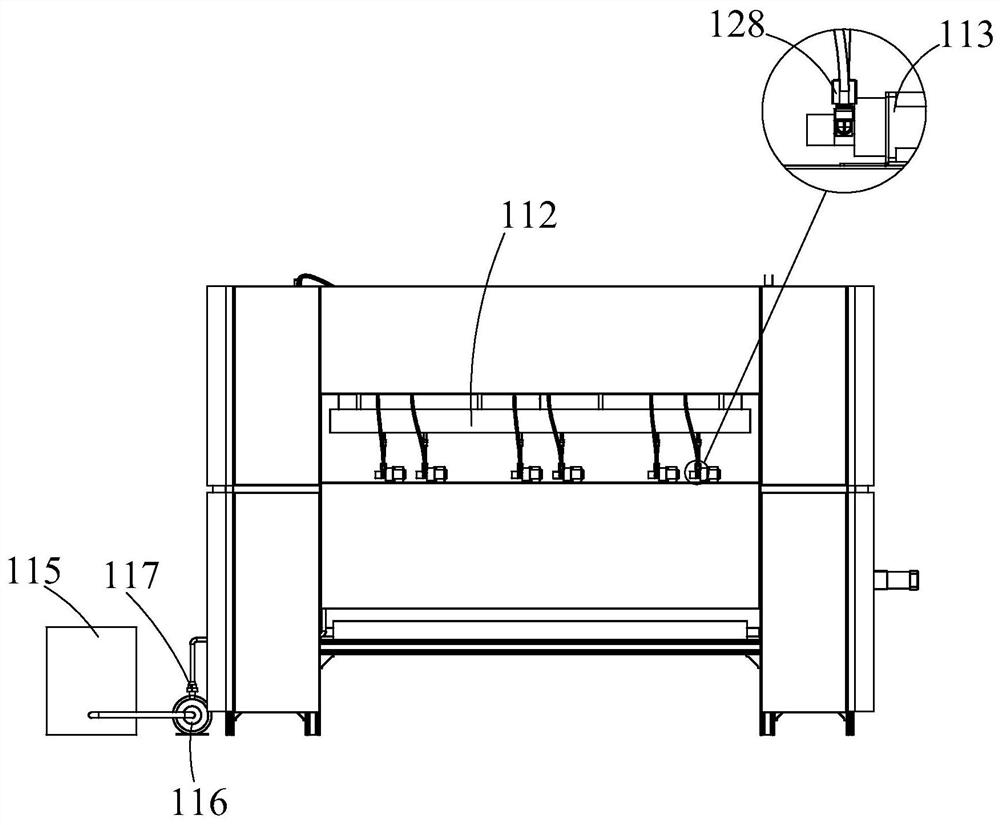

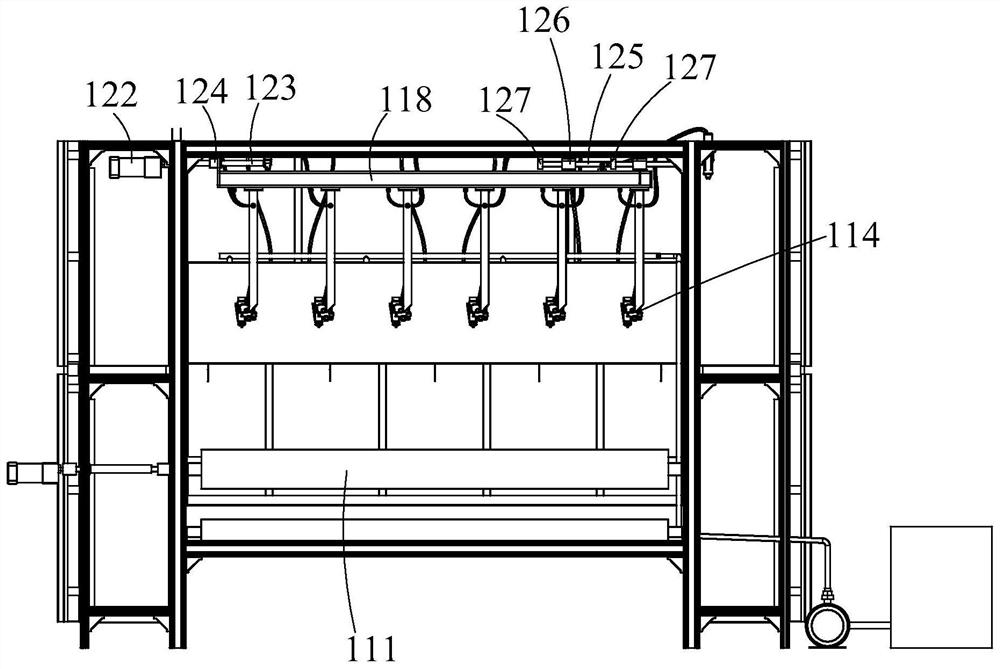

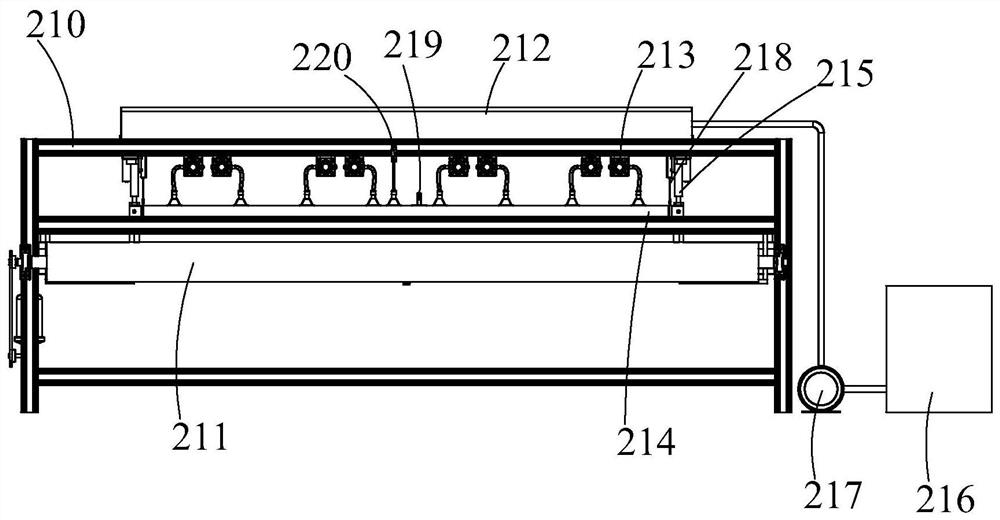

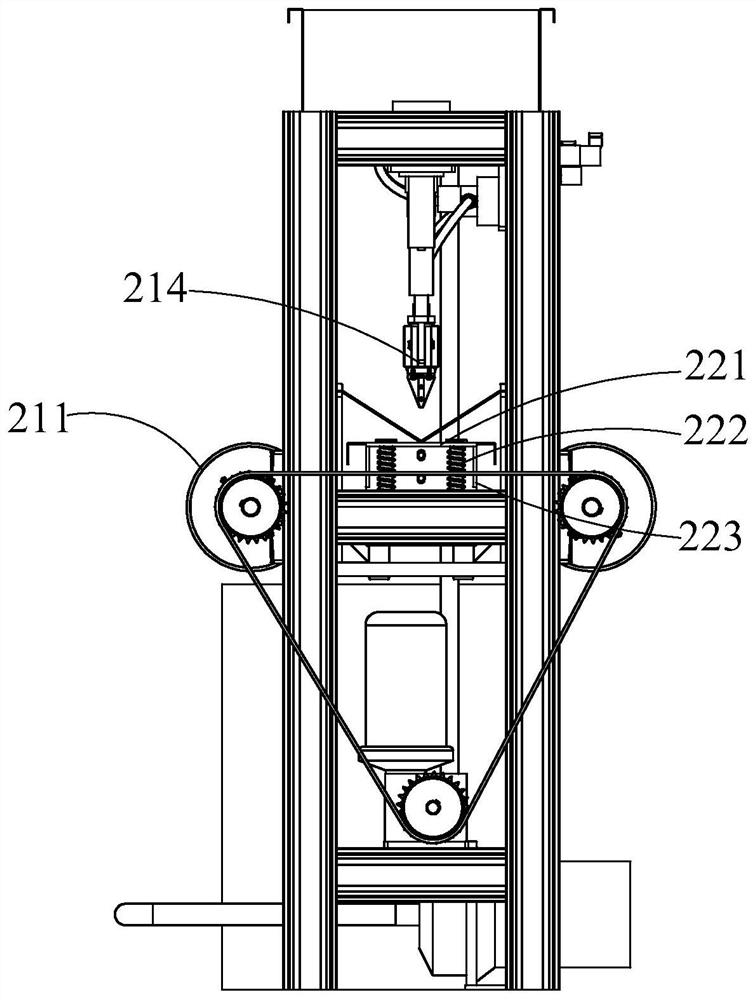

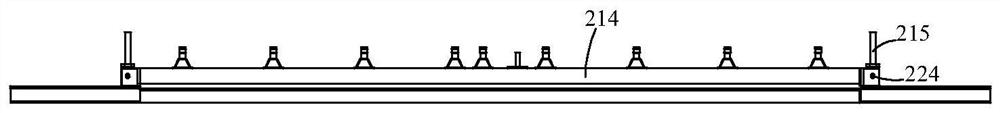

Atomizing, spraying and sizing device and method for digital printing pretreatment of high-pile fabric

ActiveCN112921539AAchieve full penetrationCompensation for pulp amount errorTextile treatment machine arrangementsTextile treatment by spraying/projectingTextile printerDigital printing

The invention relates to an atomizing, spraying and sizing device and method for digital printing pretreatment of a high-pile fabric. A cloth guide roller mechanism is mounted on a rack and used for guiding and conveying the fabric; an atomizing and spraying mechanism is mounted on the rack, is positioned above the cloth guide roller mechanism and is used for spraying white paste to the fabric; the atomizing and spraying mechanism comprises a size vat, a paste supply pump and multiple rows of atomizing nozzles; the size vat is used for containing the white paste; the paste supply pump is used for conveying the white paste in the size vat to the atomizing nozzles; each row of atomizing nozzles is provided with a set of transverse moving mechanism; and the transverse moving mechanisms drive the atomizing nozzles in the same row to move horizontally in the fabric breadth direction. When the atomizing, spraying and sizing device is used for conducting sizing pretreatment on the high-pile fabric, on the premise that the pile is not pressed down, the surface of the fabric can be evenly provided with 30 percent to 80 percent of white paste, so that a good foundation is provided for subsequent ink-jet digital printing.

Owner:HANGZHOU HONGYING DIGITAL TECH CO LTD

Full Penetration Welding Method of Single Side J-shaped Groove Joint of Vibrating Screen Box Beam Angle Joint

ActiveCN104708172BAchieve full penetrationReduce processing costsArc welding apparatusMetal working apparatusMolten bathEngineering

Owner:SHANXI PINGYANG IND MACHINERY

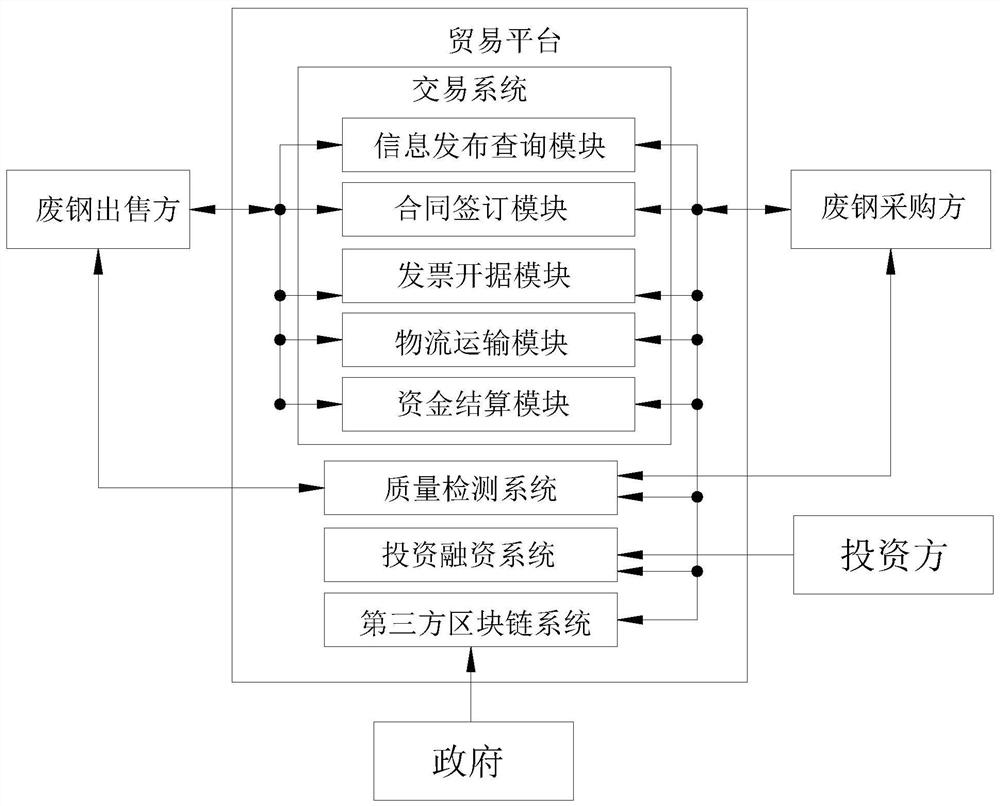

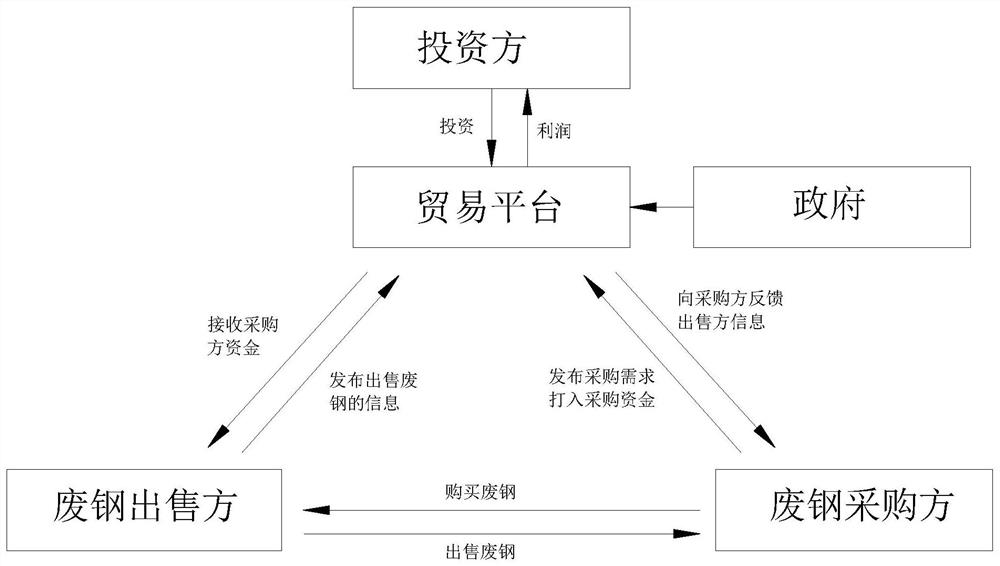

Scrap steel purchasing, selling and operating system and method

PendingCN112465644AAvoid mistrustAchieve full penetrationFinanceBilling/invoicingThird partyLogistics management

The invention discloses a scrap steel purchasing, selling and operating system and method. The system comprises a scrap steel seller, a scrap steel purchaser, a trade platform and an investor; the scrap steel seller is a scrap steel owner and sells scrap steel to the scrap steel purchaser; the scrap steel purchaser is a scrap steel purchaser and purchases scrap steel from the scrap steel seller; the investor is an investor for obtaining profits and performing investment on the trade platform; and the trade platform comprises a trade system, a quality inspection system, an investment financingsystem and a third-party blockchain platform. According to the scrap steel purchasing, selling and operating system and method provided by the invention, after the investment financing system, the quality inspection system and the block chain system are added to a traditional e-commerce platform, the long-standing fund shortage problem, especially the transaction integrity problem, including the quality integrity problem of buyers and sellers in the scrap steel trade industry and the trust problem of buyers and sellers, governments and investors on logistics, funds, bills and like of scrap steel transaction can be solved, the buyer and the seller can be relieved, and the investor and the government can be relieved.

Owner:欧冶链金再生资源有限公司

Titanium steel composite plate machining method based on transition layer control

ActiveCN114147350AAchieve full penetrationSimplified Soldering TechniquesLaser beam welding apparatusTitaniumComposite plate

The invention discloses a titanium-steel composite plate machining method based on transition layer control. The titanium-steel composite plate machining method comprises the following steps that (1) a semi-oval groove is prepared along the interface of a titanium-steel composite plate; 2) cleaning a welding area; 3) preparing a transition layer: uniformly mixing metal powder in a certain proportion to prepare the transition layer; 4) laser double-side welding: after assembling and clamping, preheating the titanium steel composite plate to 100-120 DEG C; laser double-side synchronous welding is used, and metal on the two sides is uniformly fused by controlling line energy during welding; and (5) fixing, clamping and cutting are conducted, specifically, the machined composite board is fixedly installed and cut according to the needed length. According to the method, the mechanical property of the welding joint of the titanium-steel composite plate is improved through control over the transition layer, the existing welding technology is simplified, and high-quality and efficient welding is achieved.

Owner:南京首勤特种材料有限公司

A method of manufacturing an aluminum alloy conductive rod

ActiveCN106825903BObvious technological advancementAchieve full penetrationConductorsMetal working apparatusElectrical conductorWeld seam

The invention provides an aluminum alloy conductor pole manufacturing method. According to the method, a conducting body is manufactured firstly, specifically, extrusion forming, broaching forming and mechanical turning of a conducting rod are carried out; then a conducting head is manufactured, specifically, machining of the conducting head is mainly carried out; and finally, the conducting head and the conducting rod are connected through a no-keyhole stirring friction welding technology. By means of the aluminum alloy conductor pole manufacturing method, the problem of the welding quality of large-thickness small-diameter circular seams is solved, and the method has remarkable advantages compared with the prior art. By adoption of the conductor pole manufacturing method, the joint assembly design of the conducting rod and the conducting head as well as the no-keyhole stirring friction welding technology, the qualified rate of manufacturing of conductor poles is greatly improved, the production efficiency is improved, and the production cost is reduced. Tests prove that by adoption of the aluminum alloy conductor pole manufacturing method, the manufacturing dimension precision of the conductor poles meets the design requirement, weld joints are continuous and compact in texture, the defects including pores, impurities and keyholes are avoided, and automatic control is achieved in the production process; and the yield of one-time welding is increased from 40% to 95%.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Preservative for rubber wood chip, and application of preservative

InactiveCN102241033APenetration ImprovementsAchieve full penetrationBiocideDisinfectantsPreservativeBoric acid

The invention discloses a preservative for a rubber wood chip. The preservative is prepared from the raw materials in percentage by weight: 10 to 20 percent of ethylamine, 50 to 60 percent of boric acid, and 20 to 40 percent of water. In the preservative for the rubber wood chip, the permeability of the preservative containing the boric acid can be improved well due to the ethylamine. Simultaneously, the preservative can react with dissociated formaldehyde, so that the corrosion to wood is avoided. During use, the preservative of the formula is diluted in water so that the content of the boric acid is 20 percent; and 30g of preservative is sprayed onto one square meter of the wood chip of which the thickness is 1.5mm, and then the wood chip is dried at the temperature of 140 DEG C for 4 to 5 minutes to ensure that the boric acid can permeate the sheet completely. The preservative can also be brushed onto a laminated wood board for corrosion prevention. The preservative has a good corrosion preservation function.

Owner:何汝桥

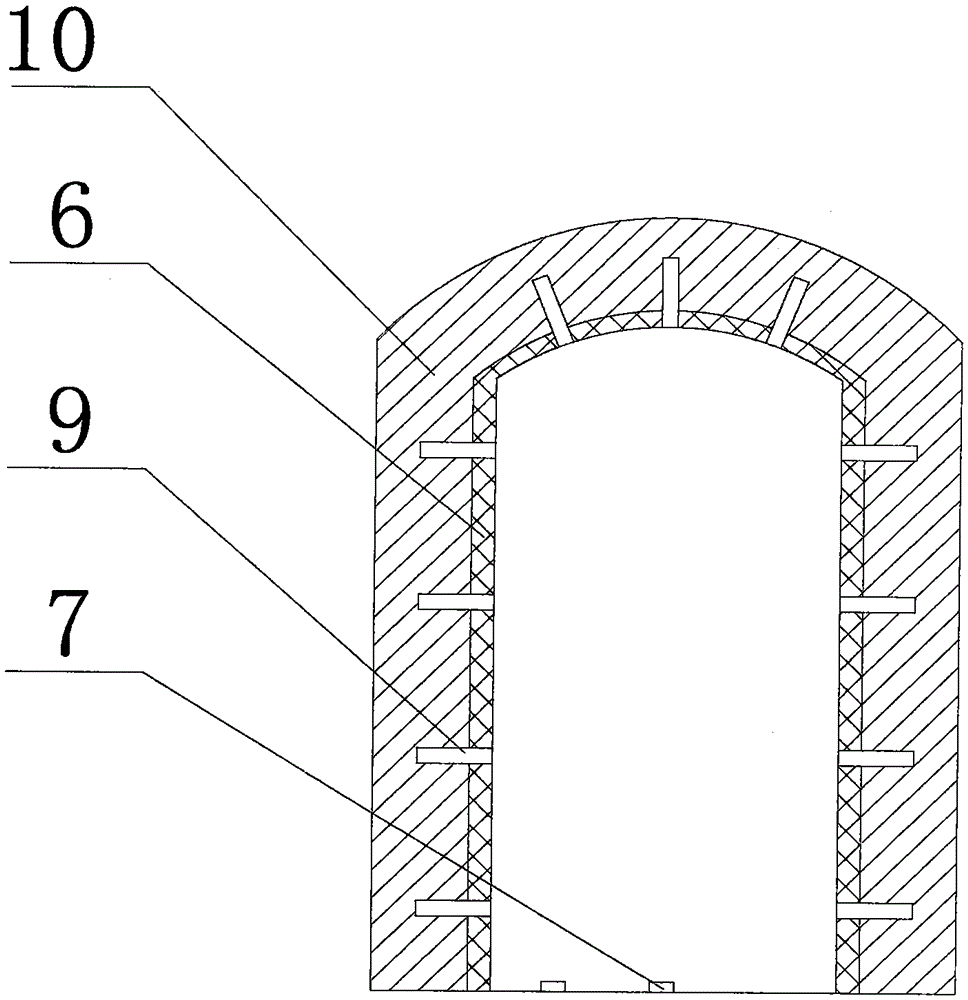

Convenient construction method for tunnel structure

InactiveCN106609673AReduce investmentImprove work efficiencyTunnelsElectricityStructural engineering

The invention discloses a convenient construction method for a tunnel structure. The construction method is characterized by including the steps of: step a, blasting the mine on a place where a tunnel is excavated, laying a horizontal guide rail on the exploded place, and excavating with an excavating device of the horizontal guide rail; step b, blasting while excavating to excavate gradually; step c, using a boring device on the horizontal guide rail to bore through holes in non-through tunnel to realize supply of wind, water and electricity on the opposite side, step d, arranging a protective wall on the opposite through tunnel in the previous step; step e, after arranging the protective wall, withdrawing cables, wind ducts and water pipes, blasting the non-through tunnel; and step f, after blasting, using excavation equipment for excavating. The construction method is safe and convenient, and improves the working efficiency, and avoids re-access of wind, water and electricity works for construction from the opposite side of through tunnel. Manpower, physical and time investment is reduced, and sustainable and stable development of mine construction and production can be maintained.

Owner:CHINA HUAYE GROUP

Full penetration welding method of double-sided laser titanium-steel clad plate based on transition layer control

ActiveCN106425100BAchieve full penetrationSimplified Soldering TechniquesWelding/soldering/cutting articlesLaser beam welding apparatusEngineeringComposite plate

Provided is a double-sided laser titanium-steel clad plate full penetration welding method based on transition layer control. The method is suitable for welding of titanium-steel clad plates. The double-sided laser titanium-steel clad plate full penetration welding method based on transition layer control is provided in order to solve the problems that in the existing titanium-steel clad plate welding process, operation is complex, accumulated heat input is large, welding stress deformation is large, and the welding efficiency is low. The method comprises following steps that 1, semi-elliptical groove is prepared along a titanium-steel clad plate interface; 2, a welding area is cleaned; 3, a transition layer is prepared, wherein the transition layer is prepared by mixing a certain proportion of metal powder to be uniform; 4, laser welding is conducted on both sides, wherein after assembling and clamping are conducted, the titanium-steel clad plate is preheated to 100 DEG C to 120 DEG C, synchronous welding is conducted on the two sides with laser, and when welding is conducted, metal on the two sides is merged uniformly by controlling the linear energy. According to the double-sided laser titanium-steel clad plate full penetration welding method based on transition layer control, by means of control of the transition layer, the mechanical property of a welded joint of the titanium-steel clad plate is improved, an existing welding technology is simplified, and high-quality and high-efficiency welding is achieved.

Owner:SOUTHWEST JIAOTONG UNIV

Air knife spraying and sizing device and method for digital printing pretreatment of high-pile fabric

ActiveCN112921538AAchieve full penetrationWon't overwhelmTextile treatment machine arrangementsTextile treatment by spraying/projectingTextile printerDigital printing

The invention relates to an air knife spraying and sizing device and method for digital printing pretreatment of a high-pile fabric. The air knife spraying and sizing device for digital printing pretreatment of the high-pile fabric comprises a rack, a cloth guide roller mechanism and an air knife spraying mechanism, wherein the cloth guide roller mechanism is mounted on the rack and is used for guiding and conveying the fabric; the air knife spraying mechanism is positioned above the cloth guide roller mechanism and is used for spraying white paste to the fabric; the air knife spraying mechanism comprises a size vat, a paste supply pump, an air knife and an air knife lifting mechanism; the size vat is used for containing the white paste and is installed on the rack; the air knife is arranged on the rack in a manner of being capable of lifting up and down through the air knife lifting mechanism; and the paste supply pump is used for conveying the white paste in the size vat into the air knife. When the air knife spraying and sizing device is used for conducting sizing pretreatment on the high-pile fabric, on the premise of not pressing down the pile, the surface of the fabric can be evenly provided with 30 percent to 80 percent of white paste, so that a good foundation is provided for subsequent ink-jet digital printing.

Owner:HANGZHOU HONGYING DIGITAL TECH CO LTD

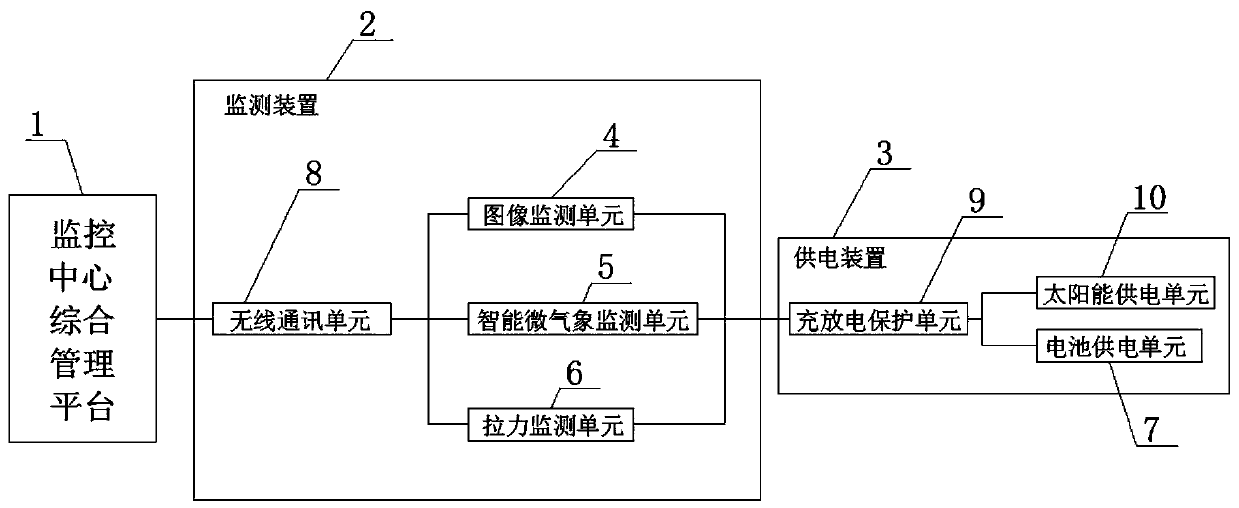

Novel icing monitoring technology based on image analysis

InactiveCN110536111ARealize online real-time monitoringMeet the actual needs of ice monitoringMeasurement devicesCircuit arrangementsCommunication unitResource utilization

The invention provides a novel icing monitoring technology based on image analysis. The system comprises a monitoring center integrated management platform, a monitoring device and a power supply device. The monitoring device comprises an image monitoring unit, an intelligent microclimate monitoring unit, a tension monitoring unit and a wireless communication unit. The novel icing monitoring technology based on image analysis is reasonable in design, and the holographic perception capability, the ubiquitous connection capability and the platform resource utilization rate can be effectively improved.

Owner:武汉纳思系统技术有限公司

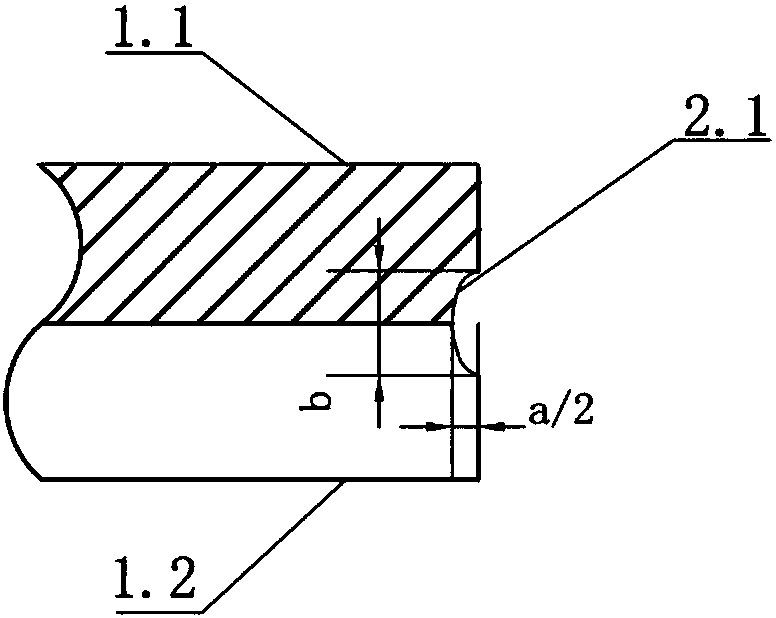

Groove butt welding structure and welding method thereof

InactiveCN104759779AShorten the lengthGuarantee welding qualityArc welding apparatusWorkpiece edge portionsNon destructiveButt welding

The invention provides a groove butt welding method. The welding method comprises the following steps: forming a first groove and a second groove in inner and outer sides of a butt welding part respectively; completely penetrating the bottom center of the first groove and welding to form a first welding channel, and then filling up the whole first groove; welding on the bottom center of the second groove to form a second welding path, and then filling up the whole second groove. According to the groove butt welding method disclosed by the invention, the welding of the whole butt welding seam is completed through improved welding material dimension, welding parameters, welding sequence and the like, so that the welding quality of the butt welding seam is guaranteed, the non-destructive examination process, the visual examination process and the dimension examination process after middle clearing and clearing are reduced, the production and manufacturing period is shortened, and the production efficiency is improved.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

A hydraulic oscillatory fracturing process for oil and gas wells

ActiveCN103912255BAchieve full penetrationAchieve openFluid removalVibration devicesFracturing fluidMicro fracture

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

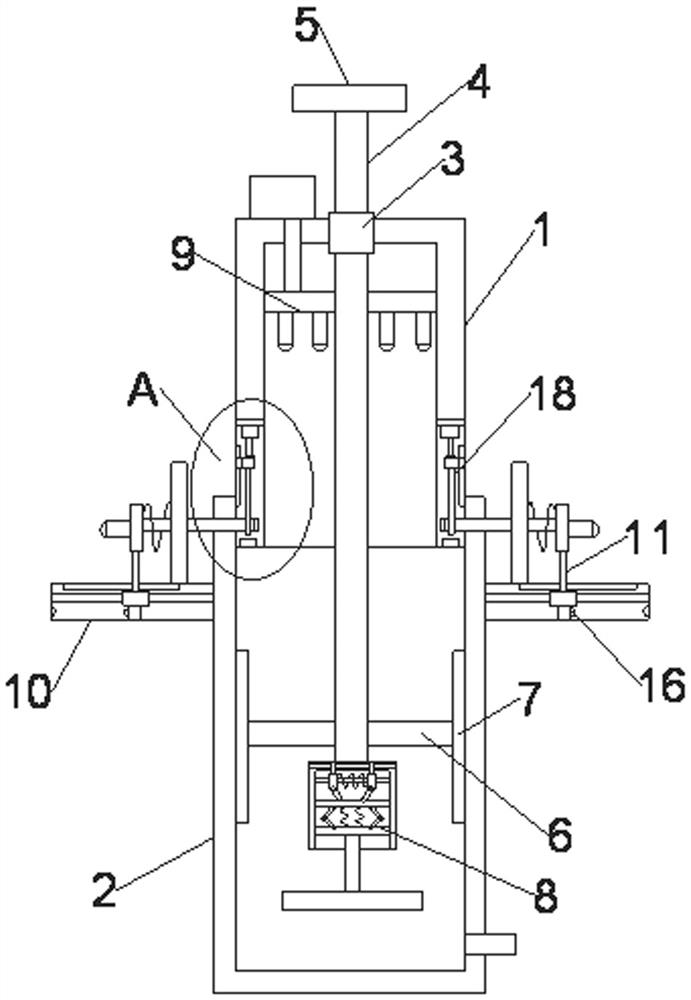

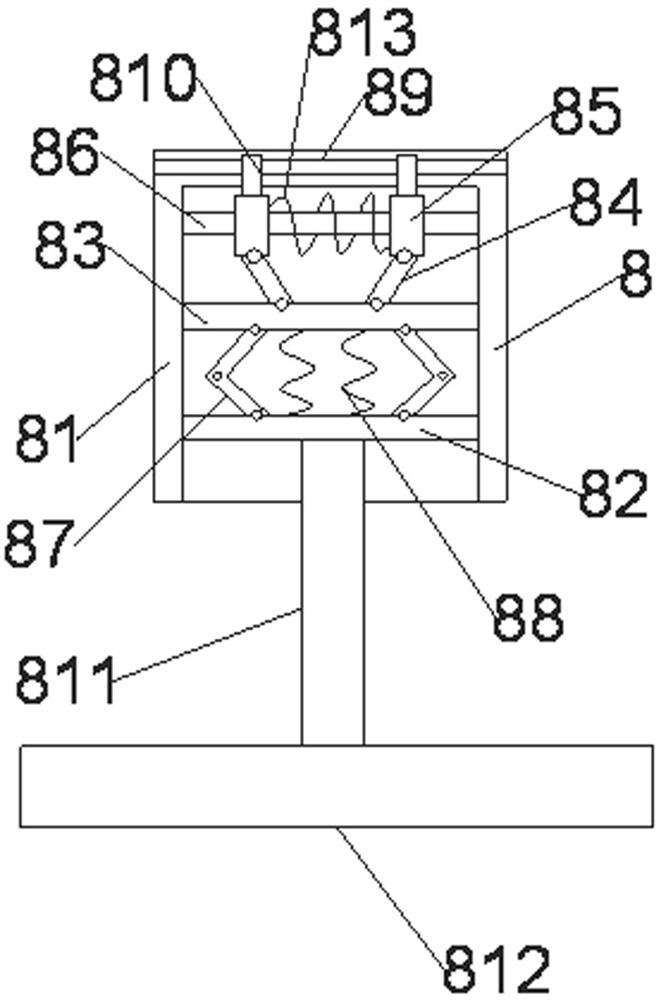

Driving type hydraulic oscillator for well drilling

InactiveCN112127795AImprove the fixed effectEasy to disassembleEarth drilling toolsVibration drillingEngineeringStructural engineering

The invention discloses a driving type hydraulic oscillator for well drilling. The driving type hydraulic oscillator comprises an upper shell and a lower shell, wherein a shaft sleeve is fixedly arranged at the top of the upper shell; a cleaning shaft fixedly penetrates through the shaft sleeve; a handle block is connected to the top end of the cleaning shaft; a cleaning rod is mounted at the bottom of the cleaning shaft; a cleaning brush is connected to the cleaning rod; an anti-collision mechanism is fixedly mounted at the bottom end of the cleaning shaft; and a cleaning mechanism is arranged on the outer top wall of the upper shell. According to the driving type hydraulic oscillator, the handle block is held by a hand to pull the upper shell, then the cleaning shaft is driven to move upand down, the cleaning rod moves up and down to drive the cleaning brush to move, and then the lower shell is cleaned.

Owner:侯江伟

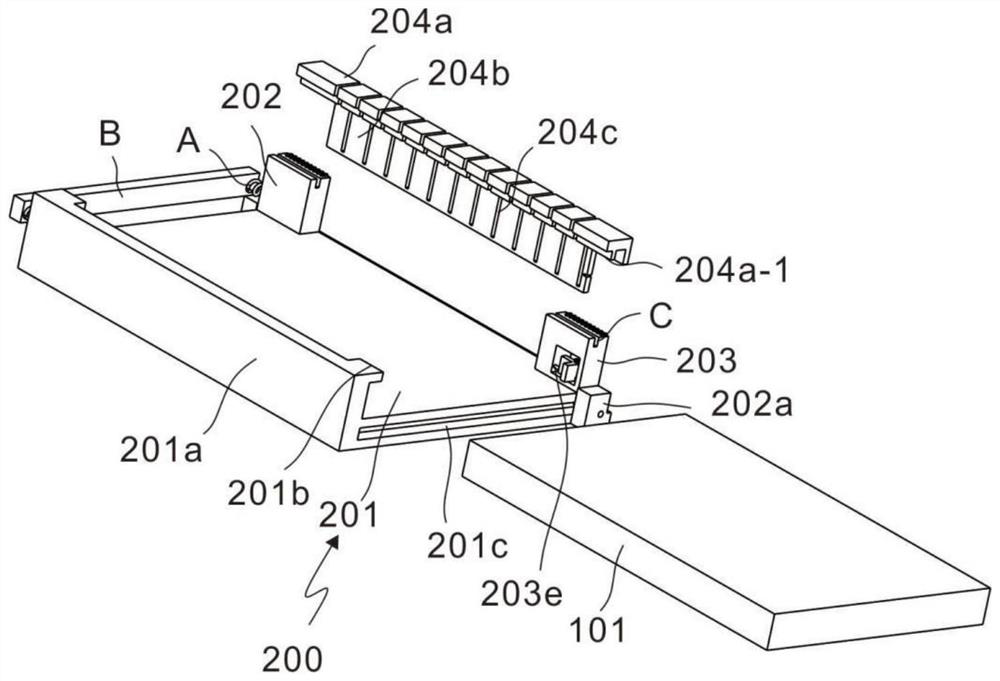

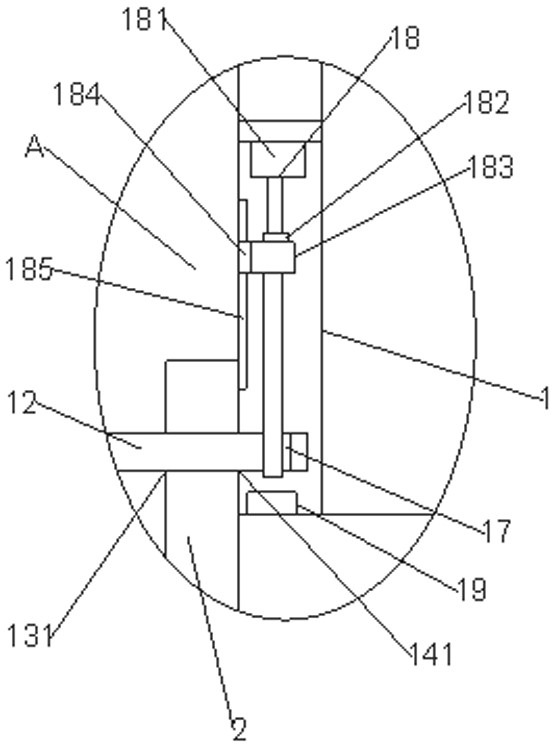

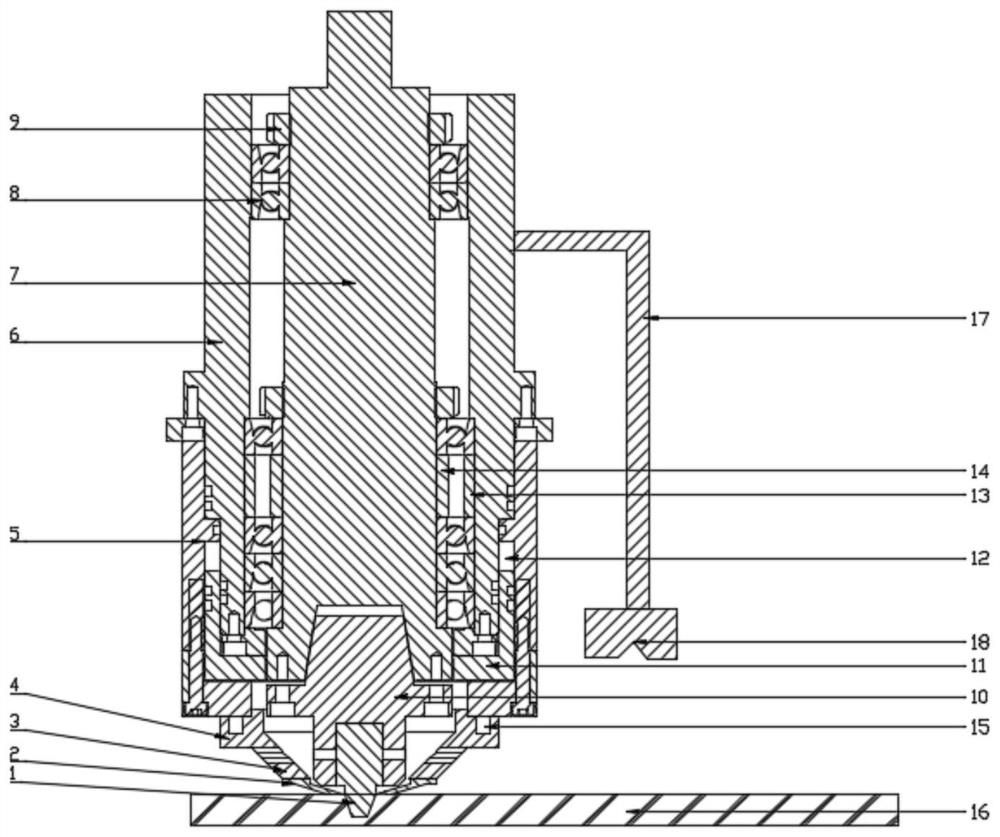

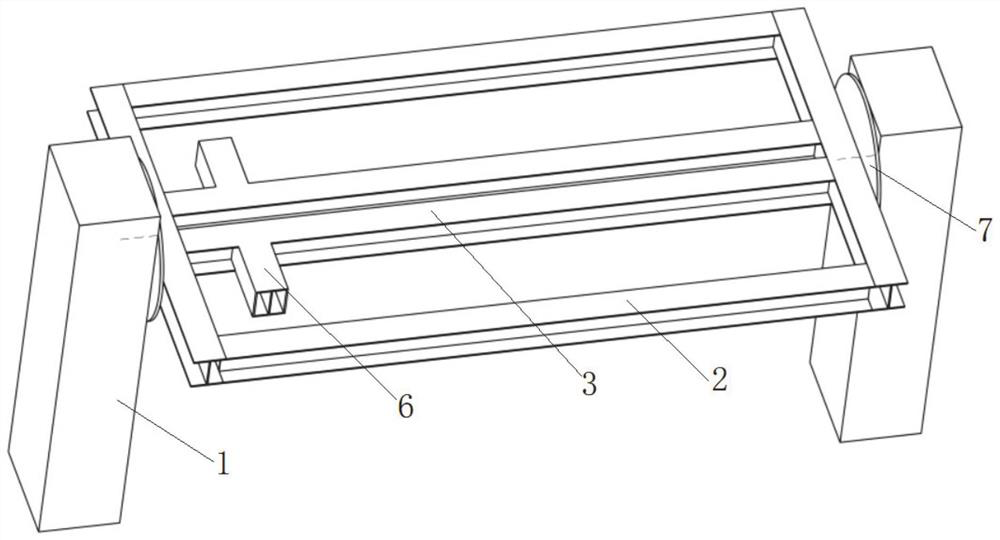

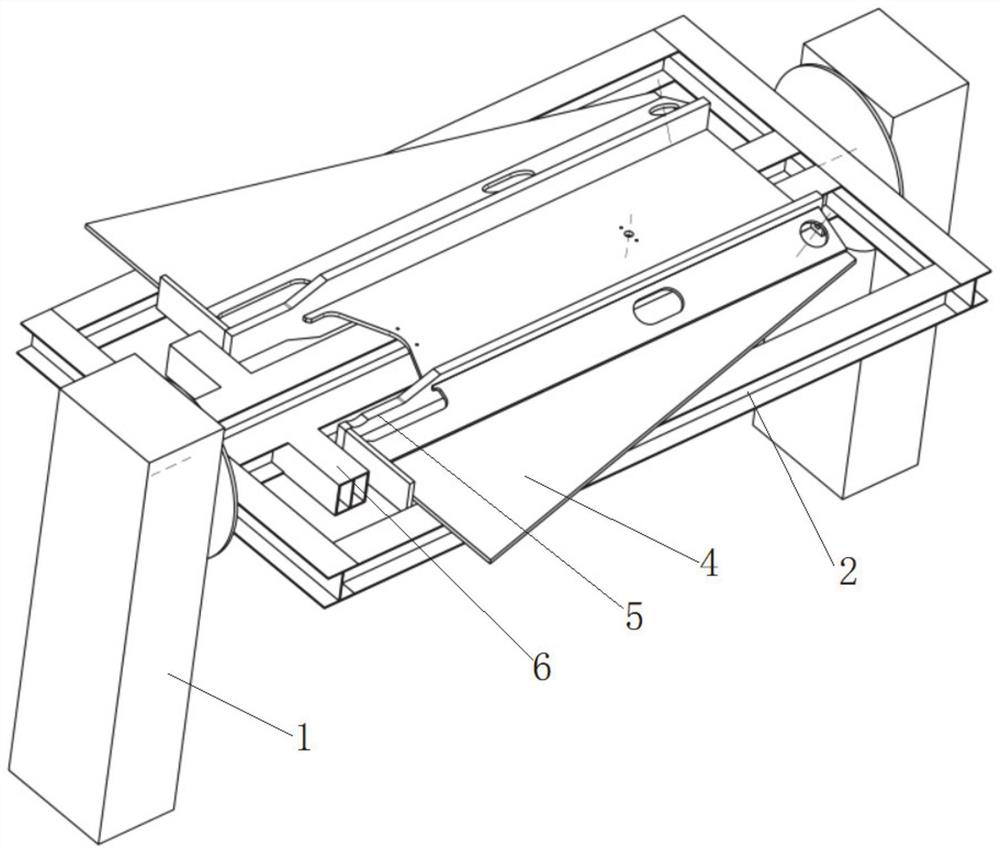

Pressure-displacement cooperative control stationary shoulder friction stir welding spindle head device

PendingCN113492256AShorten the lengthCompact and reasonable designNon-electric welding apparatusStructural engineeringWeld seam

The invention provides a pressure-displacement cooperative control stationary shoulder friction stir welding spindle head device. The device is characterized in that a shell is of a hollow structure, a rotating shaft is arranged in the shell through a bearing pack, and the tail end of the rotating shaft is connected with the head end of a welding pin through a cutter handle; an outer piston is connected with the lower portion of the shell, an oil seal cover is fixedly connected with the tail end of the shell, the oil seal cover is of a hollow structure, and an oil cavity is formed among the outer piston, the shell and the oil seal cover; and a shoulder fixing ring is fixedly connected with the bottom of the outer piston, a shoulder transition ring is connected with a static shoulder through the shoulder fixing ring, and the welding pin penetrates through the static shoulder and extends out of the static shoulder. The device realizes full penetration of a friction stir welding seam, is stable in static process, and has the advantages of compact structure, flexibility and the like.

Owner:天津益普科技发展有限公司

Molybdenum tube electrode and stainless steel electrode support welding device and welding process

PendingCN113210781AGuaranteed positioningSimple structureMetal working apparatusSoldering auxillary devicesMetallurgyStainless steel electrode

The invention discloses a molybdenum tube electrode and stainless steel electrode support welding device and a welding process. The molybdenum tube electrode and stainless steel electrode support welding device comprises a bottom plate; a molybdenum tube electrode tray tool is arranged on the bottom plate; a plurality of molybdenum tube electrodes are placed on the top of the molybdenum tube electrode tray tool in parallel at intervals; the two ends of each molybdenum tube electrode extend out of the molybdenum tube electrode tray tool; stainless steel electrode support pressing tools are symmetrically arranged on the two sides of the molybdenum tube electrode tray tool; the stainless steel electrode support pressing tools comprise a lower pressing tool used for pressing the bottom of a stainless steel electrode support on the bottom plate and an upper pressing tool used for pressing the top of the stainless steel electrode support on the two sides of the molybdenum tube electrodes; and the welding process comprises the steps of winding an Ag54Cu21Pd25 brazing wire on to-be-welded pipe orifices of the molybdenum pipe electrodes and the like. According to the molybdenum tube electrode and stainless steel electrode support welding device, the bonding strength and the sealing performance of the molybdenum tube electrodes and the stainless steel electrode support can be ensured; the flow of the internal cooling water path can be ensured; and the high-energy particle beam extraction capability of an ion source can be further improved.

Owner:合肥聚能电物理高技术开发有限公司

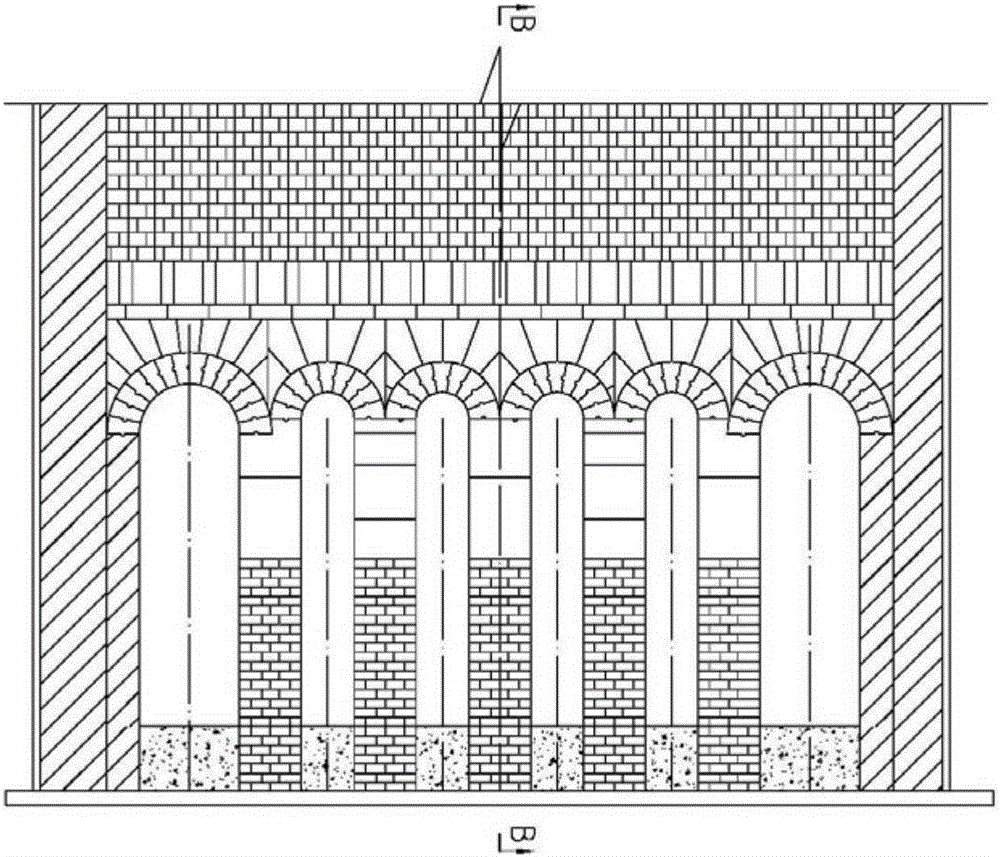

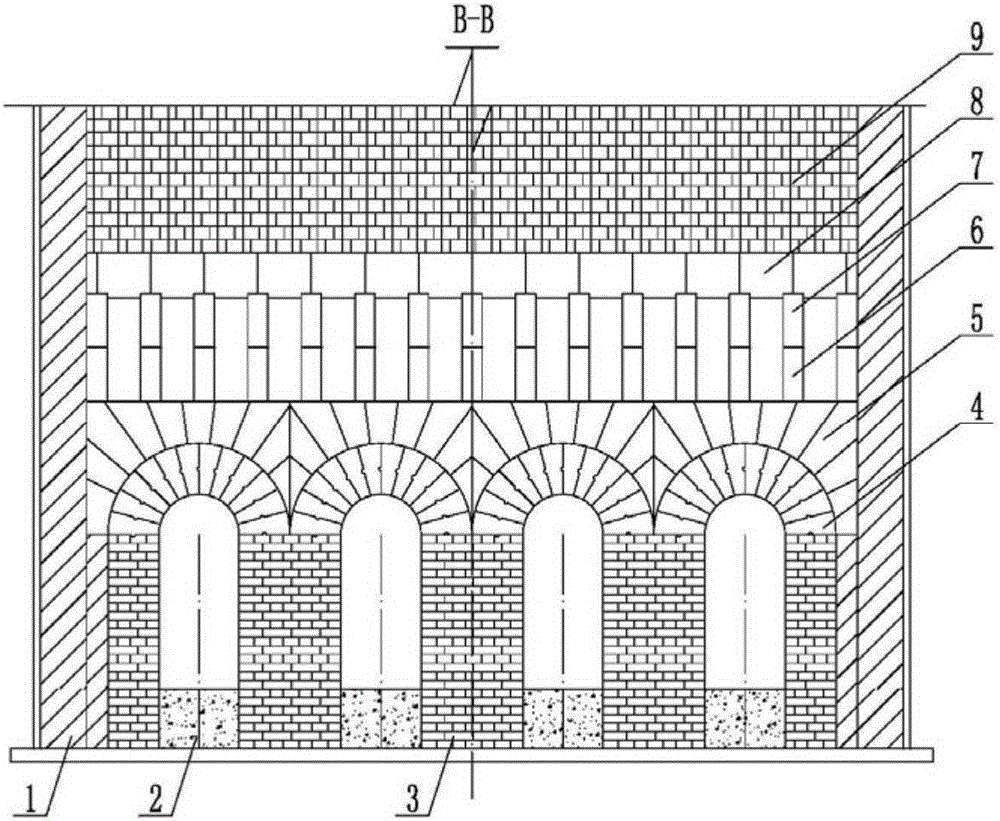

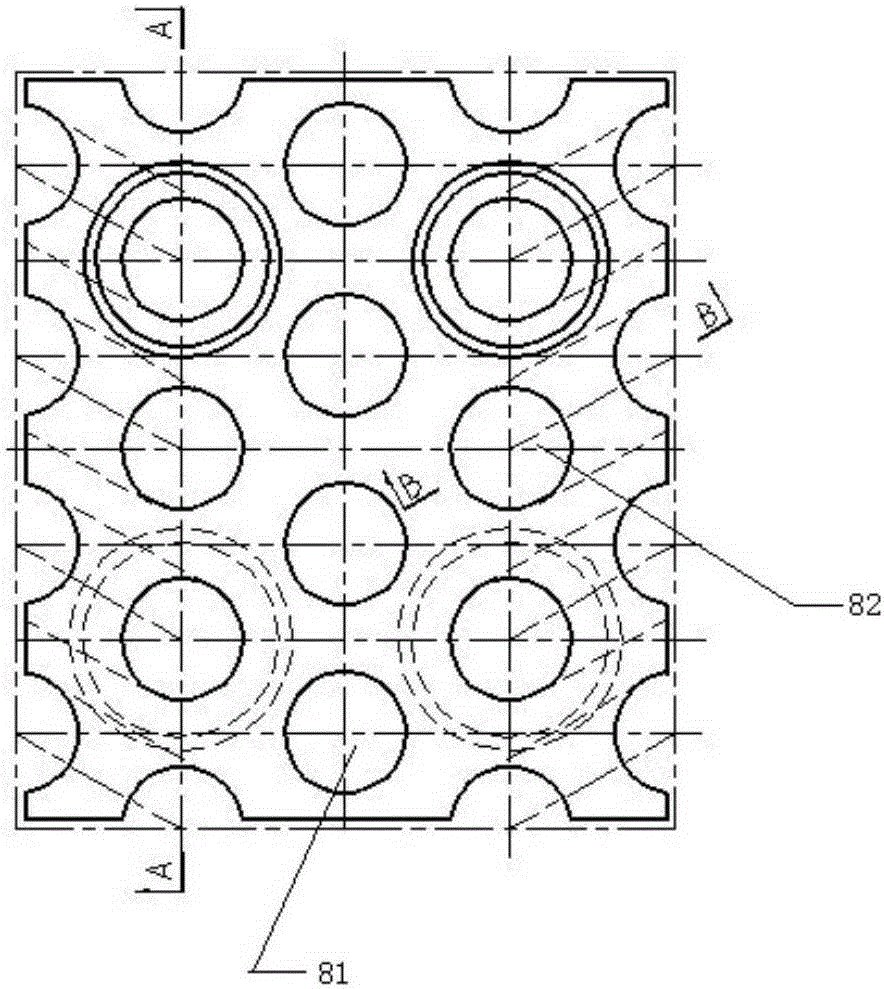

Full refractory structure supporting lattice brick furnace body structure and masonry process method

The invention relates to a full-refractory structure-supported checker brick furnace body construction and a construction technology method thereof. According to the method, a double-layer arch-shaped structure is adopted to ensure that a supporting system has enough strength so as to support an upper checker brick heat accumulator, and realize the effective engagement of the upper heat-accumulation checker bricks and a lower arc-shaped cross beam through transition bricks having a special structure, so that not only can the stability of the overall structure be guaranteed, but also the complete communication of all check brick holes of the heat accumulator can be realized; compared with a traditional brick heat accumulator, the full-refractory structure-supported checker brick furnace body construction has the advantages that the unit heat accumulation area is increased by almost one time, and the heat accumulation capability can be improved by 20%. The full-refractory structure-supported checker brick furnace body construction has the most advantage that the refractory supporting structure of checker bricks has high temperature resistance performance, with the refractoriness achieving 1500DEG C, thus completely meeting the special requirement of a heating furnace in a petrochemical industry on burning accumulated carbon below a grate with open fire, and simultaneously meeting the requirements of improving smoke temperature for preheating air and coal gas in the metallurgy industry.

Owner:鞍钢集团工程技术有限公司

A press-fit sealing material for blast furnace and preparation method thereof

The invention provides a pressed-in sealant for a blast furnace and a preparation method thereof and aims to solve the problem that existing sealants have a poor densification effect. The pressed-in sealant successively comprises, by weight, high aluminium bauxite, gangue, pyrophillite, flint clay, kyanite, clay, high alumina bauxite powder, silicon carbide powder, quartz powder, graphite and modified sliicon-alumininm sol. The prepared sealant matrix has high content and good fluidity, can slowly wriggle in a small slit and has good permeability. The modified sliicon-alumininm sol has short bonding and hardening time, the strength is suitable, and a hardened product has elasticity and will not become hard and fragile or crack. The product has good endophilicity and excellent seal performance, and is firmly glued with a steel casing and a furnace lining to form an integral body so as to greatly prevent gas from fleeing along the slit.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

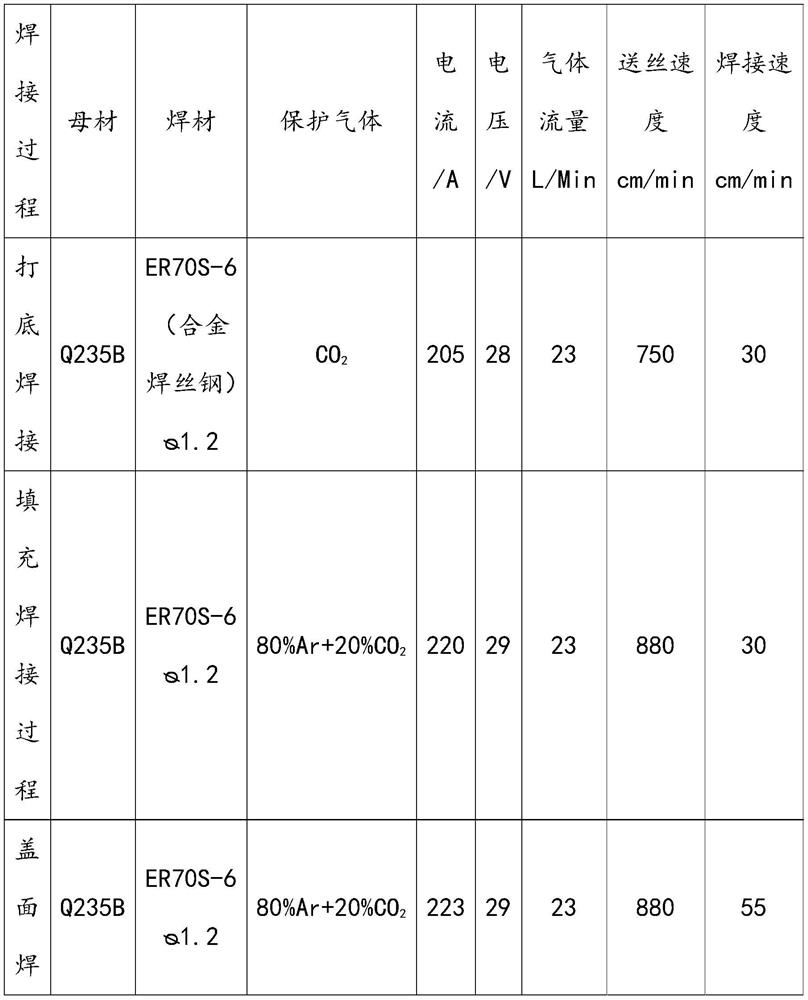

Diesel engine rack single-piece double-face double-arc synchronous gas shielded welding process

PendingCN113478055AGuaranteed weld pass rateAchieve full penetrationWelding accessoriesDieselingShielding gas

The invention discloses a diesel engine rack single-piece double-face double-arc synchronous gas shielded welding process, solves the problems of diesel engine rack single-piece poor welding seam quality and low production efficiency in the prior art, and has the beneficial effects of ensuring the welding seam quality and realizing full penetration welding without leaving a gap. According to the specific scheme, the diesel engine rack single-piece double-face double-arc synchronous gas shielded welding process comprises the steps that diesel engine rack single-piece protection is conducted through protection gas in the backing welding process so as to ensure that base metal for backing is melted, and argon and carbon dioxide in the set proportion serve as the protection gas in the filling welding and capping welding process, so that welding spatter is avoided in the forming and welding process of each layer of welding seam, and welding currents are different in the backing welding, filling welding and capping welding processes.

Owner:中国船舶重工集团柴油机有限公司

A processing method of titanium-steel clad plate based on transition layer control

ActiveCN114147350BAchieve full penetrationSimplified Soldering TechniquesLaser beam welding apparatusTitaniumComposite plate

Owner:南京首勤特种材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com